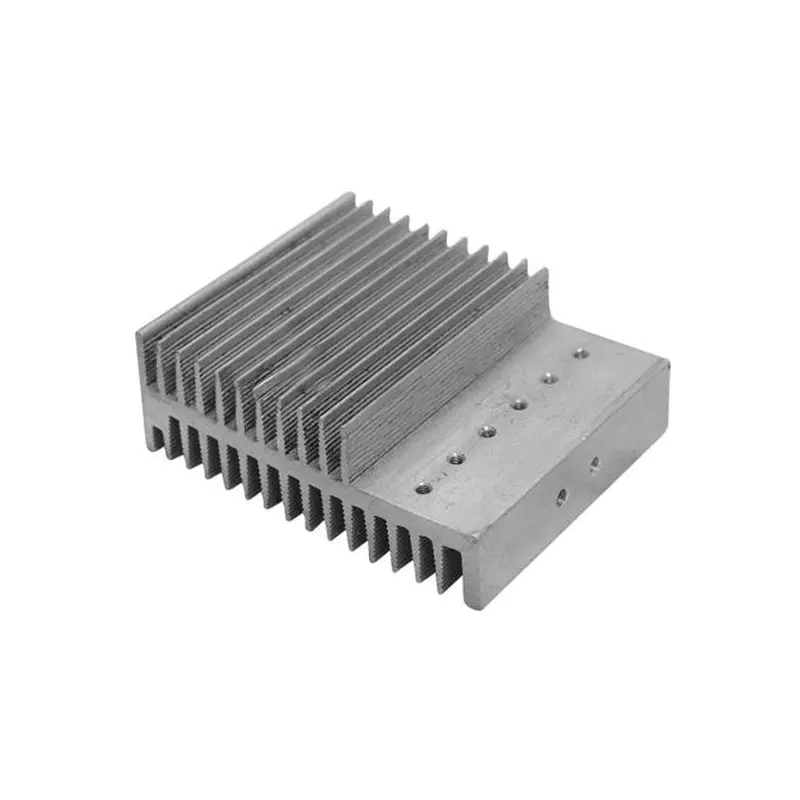

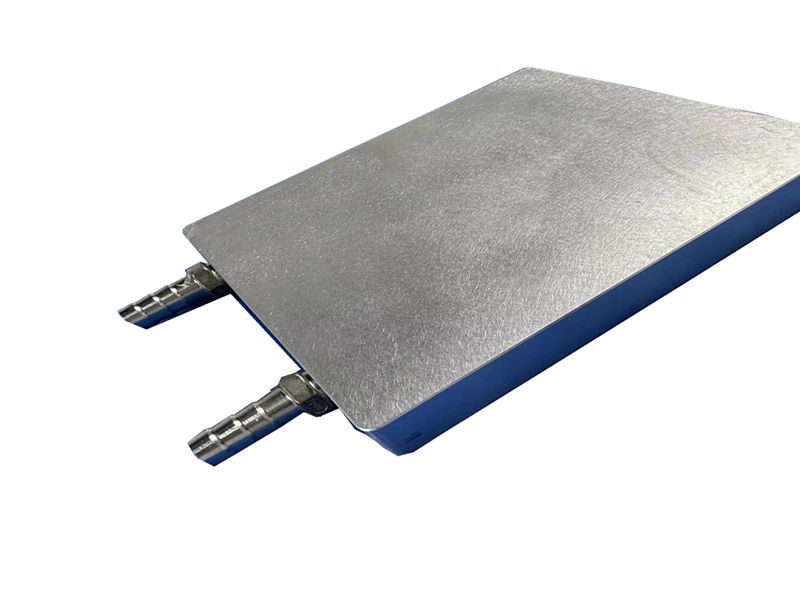

High Power Inverter Friction Stir Welding Liquid Water Cooling Cold Plate for IGBT

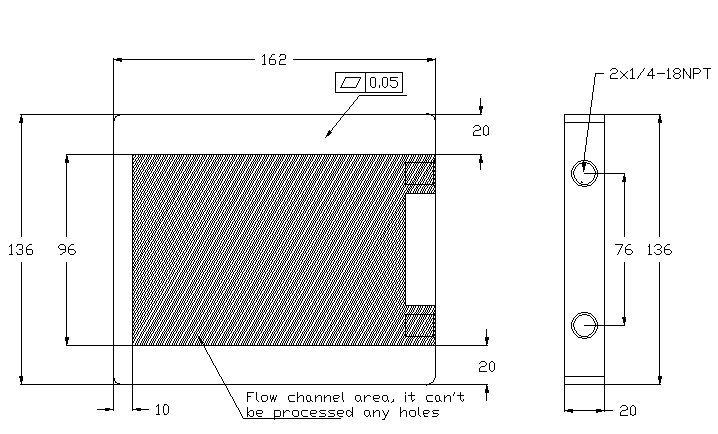

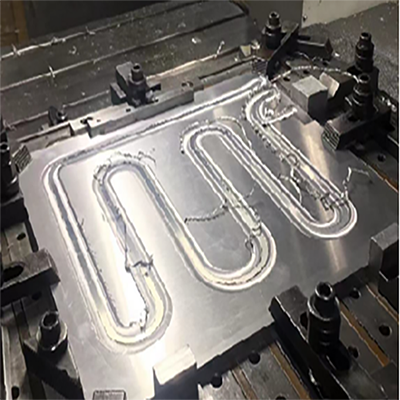

The base material of this high power Inverter friction stir welding liquid water cooling cold plate for IGBT is aluminum 6063.Longitudinal channels are formed on the base by CNC machining,and then milled at both ends of the transverse interval,the channels are tightly connected by friction welding.In the direction of higher compressive strength and thinner thickness,the technology has been successfully applied to the liquid water cooling cold plate for inverters.The surface of this Liquid Water Cooling Cold Plate is hard anodized and has a smooth,burr-free surface,making it worth your while choose a device that can withstand harsh usage environments and long-term fluid erosion.In the actual liquid water cooling cold plate design process,engineers will choose a variety of specifications of IGBT module,and the design of an IGBT inverter liquid water cooling cold plate with optimal heat dissipation performance is the difficult part of the design process.Generally speaking, the following steps need to be considered regarding the thermal performance of IGBT.The choice of heat dissipation material is crucial.In general,aluminum alloy is a more common choice due to its excellent thermal conductivity and strength.On the other hand,copper is also a commonly used material because of its superior thermal conductivity to aluminum.Depending on the type of liquid water cooling cold plate, designing specific runners requires different process designs.For specific liquid water cooling cold plate design, you can contact us and we can provide comprehensive information about flow path design can contact us,we can provide comprehensive information about our liquid water cooling cold plate designs,including dimensions, manufacturing process, material selection, flatness specifications and inlet/outlet requirements.This will help engineers make informed decisions.