Dc charging pile integrates power electronics technology, embedded technology and IoT technology. The biggest sticking point is power electronics. The power electronics technology in the field of charging piles is rectifier technology. The power size of the rectifier, from 3kW in the 1990s to 20kW-60kW, has progressed rapidly, but the mainstream circuit topology is still three-phase Vienna (PFC), LLC or phase-shifted full bridge (DC/DC). Rectifier technology in the 1990s is the main application of communication power supply, the output voltage range is very narrow, 42V-56V; Applied to DC charging pile, the output voltage range is very wide, 200V-1000V. A wide voltage range is achieved by connecting the secondary sides of the transformer in series or in parallel, and there have been some innovations in this regard over the years. Due to the very harsh use environment of charging piles, the industry has also been seeking a breakthrough in heat dissipation. Four heat dissipation methods, such as forced air cooling, independent air duct, liquid cooling and natural cooling, are used in different types of DC charging piles.

Forced Air Cooling

Forced air cooling refers to the heat dissipation method by forcing the circulation of air through the fan. The fan directly blows or exhausts the "heat source devices" (such as MOS tubes, transformers, inductors, electrolytic capacitors, etc.) to take away the heat by strong exhaust air. The heat source device, such as the MOS tube, needs to be close to the radiator, and the heat of the MOS tube is dispersed, because the size of the MOS tube is small, the heat is concentrated, and the accumulation is fast. If the radiator is larger, the fan speed can be smaller.

Forced air cooling is the most common heat dissipation method for switching power supply products used indoors, such as server computers and desktop computer power supplies. Compared with natural cooling, forced air cooling is faster and more efficient. The disadvantages of forced air cooling are: low protection level and loud noise.

In the way of forced air cooling, a special design is to use forced fans and heat pipes to dissipate heat, which is particularly common in high-power electronic products (such as laptops, high-performance desktop computers, etc.). The principle of using heat pipes is to complete the transfer of heat through the evaporation and condensation of the liquid inside the heat pipe. Specifically, there is a low and a high inside the heat pipe, the low is close to the heat source, the high is connected to the higher position of the fan. The high temperature on the heat source causes the liquid inside the heat pipe to evaporate, and the steam will flow from the low place to the high place, and after flowing to the high place, due to the help of the fan, the steam will quickly condense into a liquid, and the heat transfer is completed. The use of heat pipes can solve the heat dissipation problem without increasing too much space, and does not affect the performance and appearance of the product. However, this heat dissipation method has not been applied in the field of charging modules.

Independent Duct

Independent air duct may not be an academic term, nor was it once a conventional term in the circle, but due to the use of energy efficient electricity, "independent air duct" has been written into the SOR of automotive products as a conventional heat dissipation method.

The independent air duct means that the PCBA is completely sealed, and the heat generated by the heat source device is transmitted to the teeth of the radiator in the way of conduction, and the fan can only blow or exhaust the teeth of the radiator to take away the heat generated by the sealing part. Using this heat dissipation method, the heat is evenly distributed by the large area of the heat sink, at room temperature, the fan can remove the heat at a very low speed (4000 RPM), so the noise can be very small. The noise at room temperature can be controlled within 45 decibels. Since the PCBA is sealed, the "dust free" of the IP6X is guaranteed. Low noise and high protection are the two major advantages of independent air duct design.

Liquid Cooling

The PCBA process of the liquid cooling method is similar to that of the independent air duct, which is also to completely seal the PCBA, and seal the entire die casting body by the way of grooves and sealing rings. The difference is that the heat of the liquid cooling method is conducted to the bottom of the die casting body, and the heat is taken away by the flow of the liquid in the water pipe. The PCBA is buried under the water channel, with water inlet and outlet. Heat is carried away by the flow of liquid, but how does it eventually escape? The on-board charger, motor controller and other components of the electric vehicle are mostly liquid cooling heat dissipation, these components are very small, and the heat treatment part is shared with other parts of the car. The heat is ultimately dispersed by the radiator and taken away by the pressure difference of the fan.

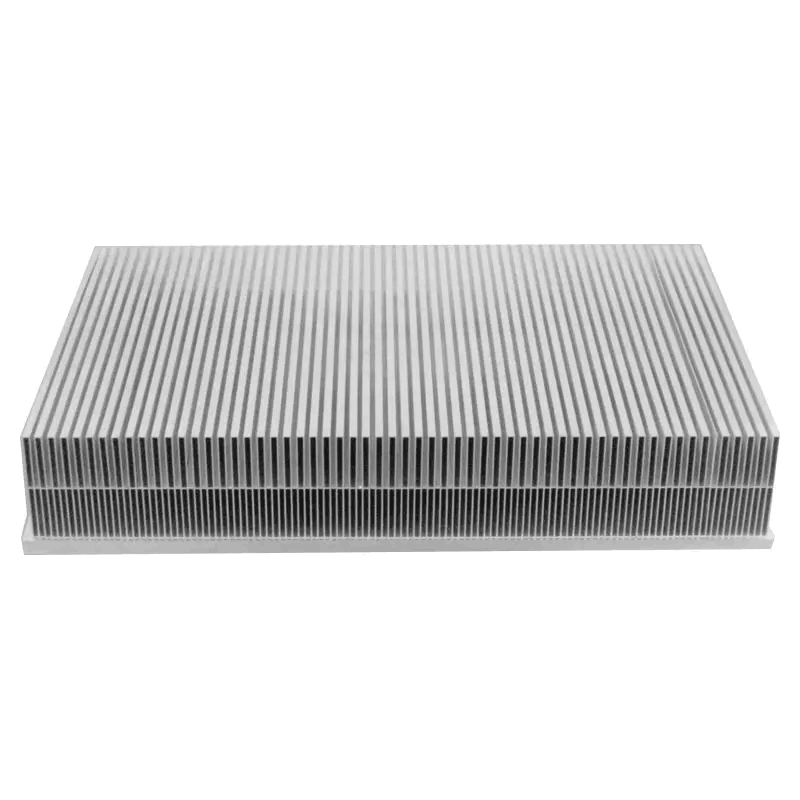

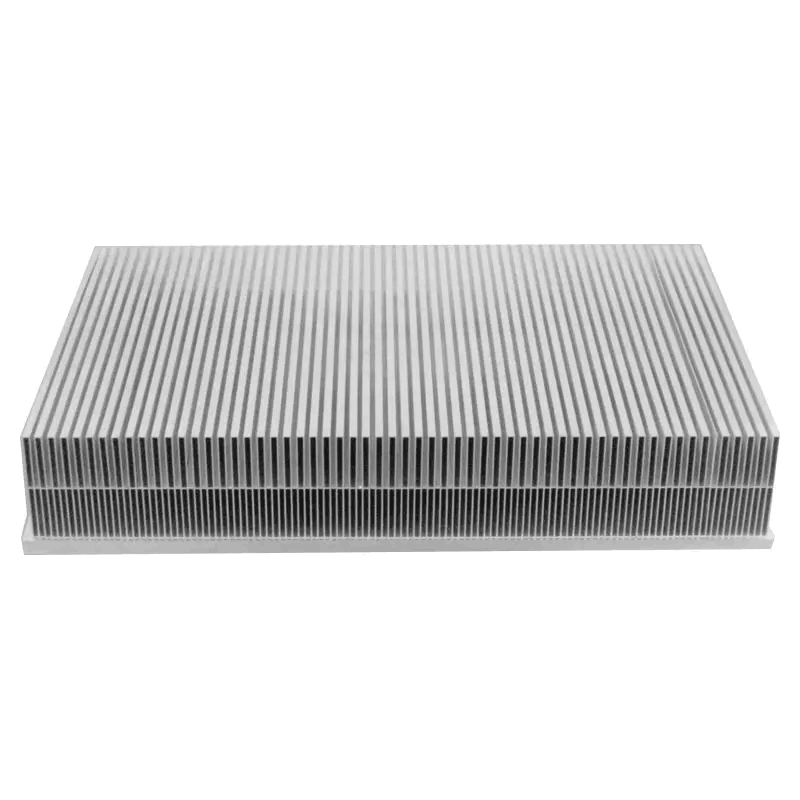

Natural Cooling

Natural cooling is the use of high thermal conductivity of metal materials to take away heat and dissipate heat into the air cooling method, using the natural convection between the outlet and the inlet to complete. In the absence of specific wind speed requirements for natural convection, the heat sinks used are copper-aluminum sheets, aluminum extrusions, heat pipes, machined or alloy castings. Because natural heat dissipation mainly uses natural air flow, the area and layout of heat dissipation need to be planned in advance in product design, otherwise it will lead to insufficient or uneven heat dissipation.

There is only so much heat that natural cooling can take away. In order to take away more heat, the volume of the radiator must be larger, and correspondingly, the weight is heavier. For the home 7kW low-power DC charging pile, after going to OBC, the ultimate solution is natural cooling.

Lori has been focusing on heat dissipation for nearly ten years, and we have rich experience in thermal management. Do you need to customize an efficient heat sink for your charging pile? Contact us!