The application of water-cooled plate in military equipment is more and more extensive, mainly because of its efficient thermal management ability. The following are some specific applications and advantages of water-cooled plates in military equipment:

Application

1. Radar system:

○ Military radar systems process a lot of data and generate a lot of heat. The water-cooled plate can effectively remove heat from key electronic components, ensuring stable operation of the system.

2. Communication equipment:

○ Military communication equipment often operates under high loads, and water-cooled plates help maintain the normal operating temperature of these equipment to avoid failures caused by overheating.

3. Missiles and Drones:

○ Electronic devices in missiles and drones generate a lot of heat in high-speed flight and complex environments, and water-cooled plates can ensure that these devices can still operate normally under extreme conditions.

4. Electronic Warfare equipment:

○ Electronic warfare equipment needs to run for a long time and handle high-power signals, and water-cooled plates provide reliable heat dissipation solutions to prevent equipment overheating.

5. Computer servers and data processing centers:

○ Military computing and data processing equipment have high heat dissipation requirements, and water-cooled plates help improve system performance and reliability.

Advantage

1. Efficient heat dissipation:

○ The heat dissipation efficiency of the water-cooled plate is higher than that of the traditional air-cooled system, and the heat generated by the equipment can be taken away faster.

2. Stability and reliability:

○ By maintaining the equipment within the appropriate temperature range, the water-cooled plate improves the stability and reliability of military equipment.

3. Reduce equipment volume and weight:

○ Water-cooled systems are usually smaller and lighter than air-cooled systems with the same heat dissipation capacity, helping to reduce the weight and volume of the overall equipment, especially in applications that are sensitive to weight and space.

4. Reduce noise:

○ Water cooling systems operate with low noise, which is conducive to use in military applications that require a low noise environment.

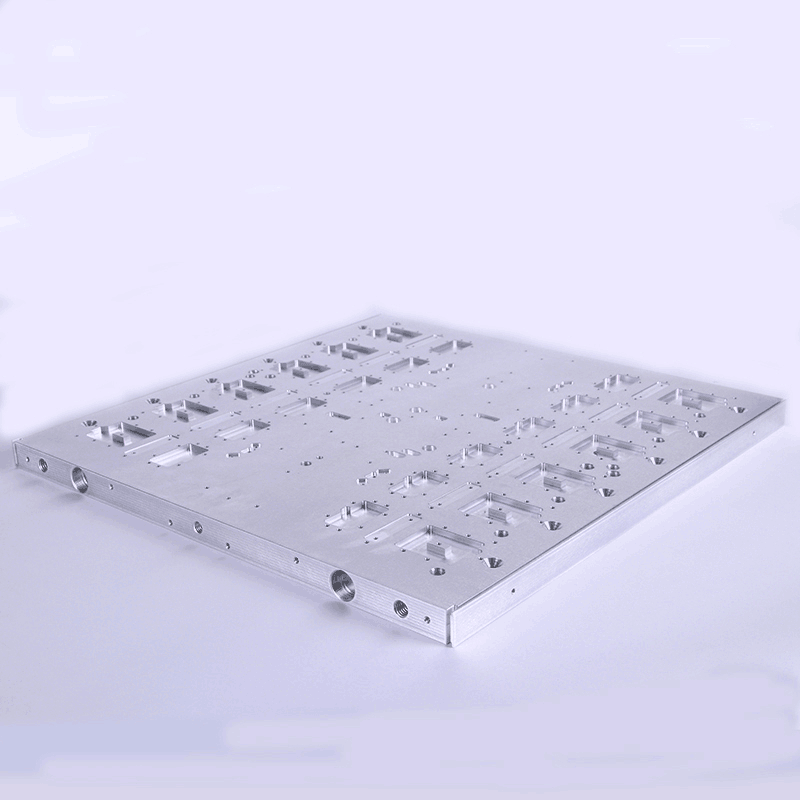

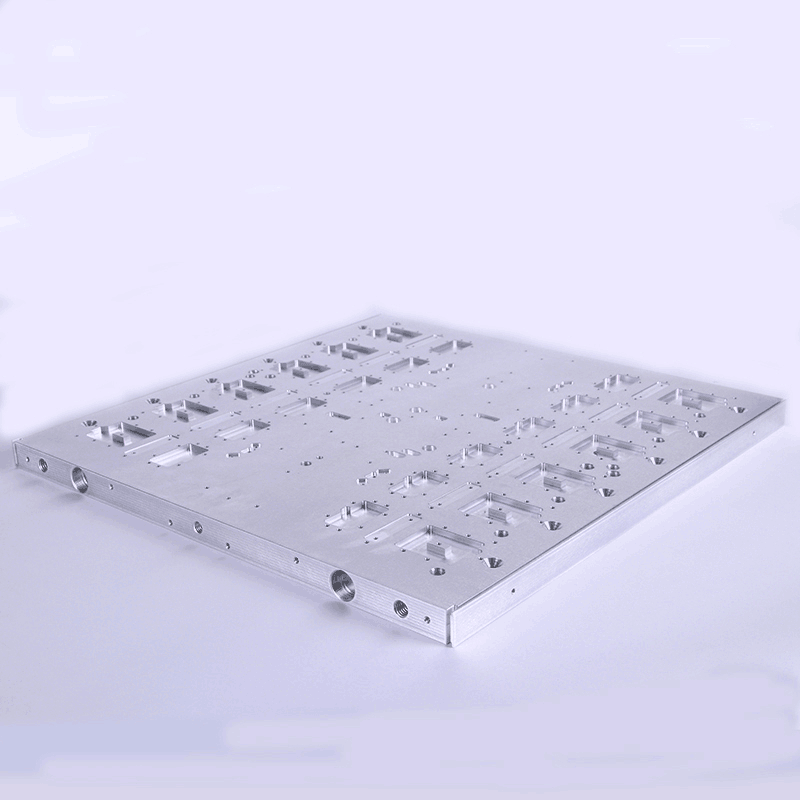

5. Flexibility and customizability:

○ Water cooling plate can be customized according to the specific needs of different equipment to provide the best heat dissipation solution.

Challenge

1. Environmental adaptability:

○ Military equipment often works in extreme environments, including high temperature, high humidity, low temperature and high radiation environment. The water-cooled plate and its coolant need to maintain stable performance under these conditions.

2. Durability and reliability:

○ Military equipment usually requires long-term stable operation, and the design of water-cooled plates must consider corrosion, leakage and wear problems in long-term use.

3. Maintenance and repair:

○ The maintenance and repair of military equipment is usually more difficult, and the water-cooled plate design needs to be easy to maintain and replace, reducing maintenance time and cost.

4. Energy Efficiency:

○ Energy consumption for cooling systems is also a key concern, especially in front line and field environments where energy is limited. Water cooling plate systems need to be energy efficient.

Solution

1. Advanced material application:

○ The use of corrosion-resistant, high-strength materials, such as titanium alloy, stainless steel and high-performance composite materials, can improve the environmental adaptability and durability of water-cooled plates.

2. Intelligent cooling Management:

○ Integrated intelligent control system, through real-time monitoring of temperature and flow, dynamic adjustment of coolant flow rate and temperature, optimize energy efficiency and ensure system stability.

3. Modular design:

○ Water cooling plate adopts modular design for quick replacement and maintenance. Simplify maintenance with quick-disconnect connections and standardized interfaces.

4. Nanotechnology and Coatings:

○ The high thermal conductivity coating and anti-corrosion coating manufactured by nanotechnology can significantly improve the heat dissipation performance and durability of the water-cooled plate.

5. Optimized coolant formula:

○ Research and develop new coolant formulations to improve thermal conductivity and extreme environmental resistance, and reduce coolant evaporation and corrosion problems.

Future outlook

With the continuous progress of science and technology, the application of water-cooled plate in military equipment will continue to expand, and its technology will continue to improve. Here are some possible directions for the future:

1. Adaptive cooling technology:

○ Future water-cooled plates may integrate adaptive cooling technology to automatically adjust the cooling mode according to real-time heat load, providing the optimal thermal management solution.

2. Integrated multi-function module:

○ The thermal management, power management, data transmission and other functions are integrated together to form a multi-functional module to improve the overall performance of the system.

3. Efficient and low-cost manufacturing technology:

○ The use of 3D printing, laser processing and other advanced manufacturing technology, reduce production costs, improve production efficiency, and can create more complex and efficient cooling structures.

4. Environmentally friendly design:

○ The future design of water-cooled plates will pay more attention to environmental friendliness, using renewable materials and environmentally friendly coolants to reduce the impact on the environment.

Conclusion

The application of water-cooled plate in military equipment not only solves the heat dissipation problem of high heat density electronic equipment, but also improves the overall performance and reliability of the equipment. Although there are some technical challenges, these challenges can be effectively solved through continuous technological innovation and design optimization. In the future, with the application of new materials, new technologies and new processes, water-cooled plates will continue to play an important role in the military industry, providing more powerful thermal management solutions for military equipment.