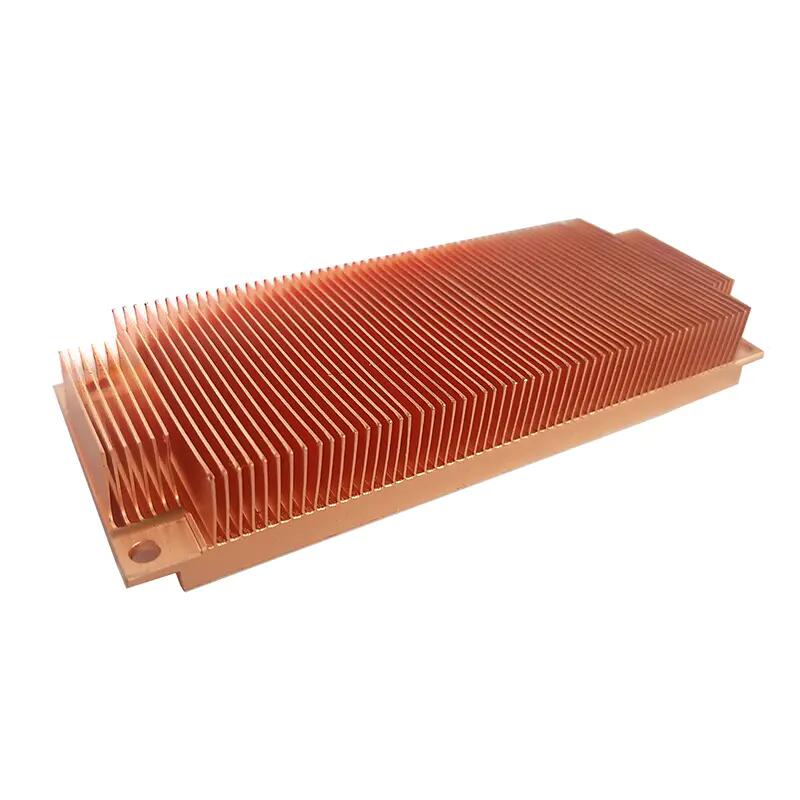

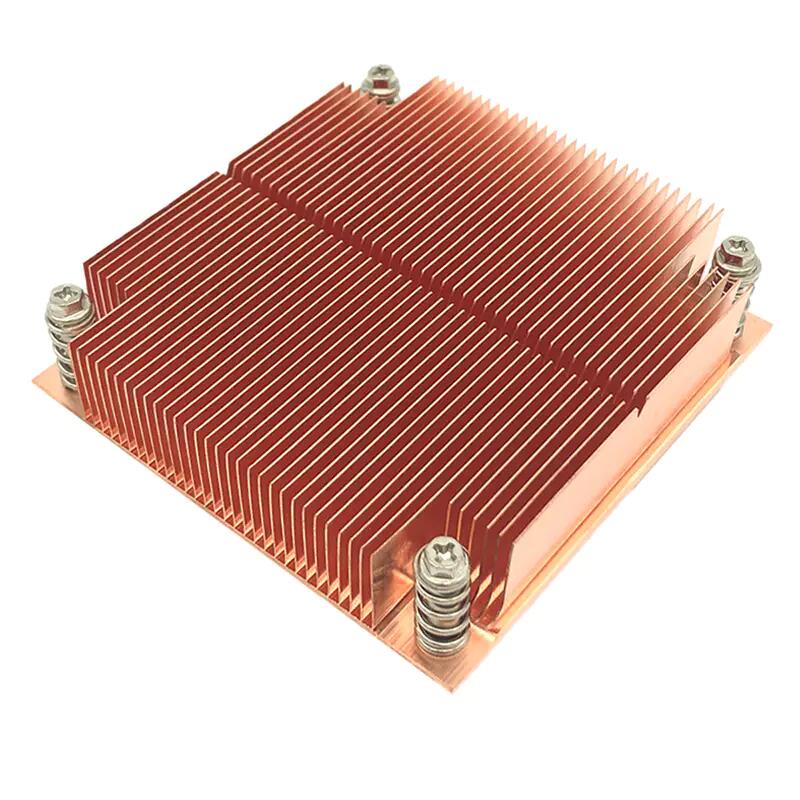

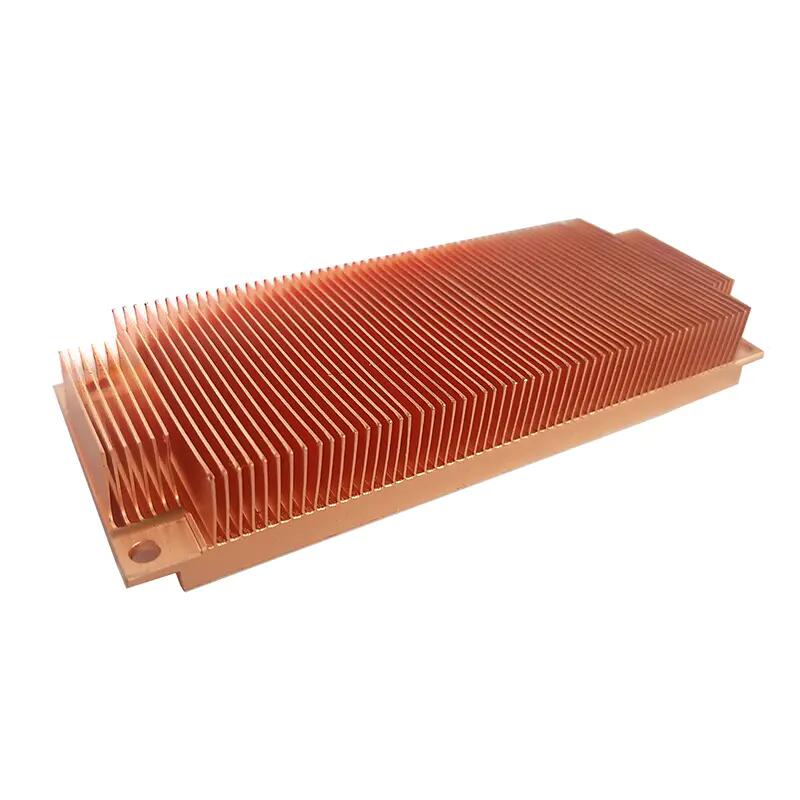

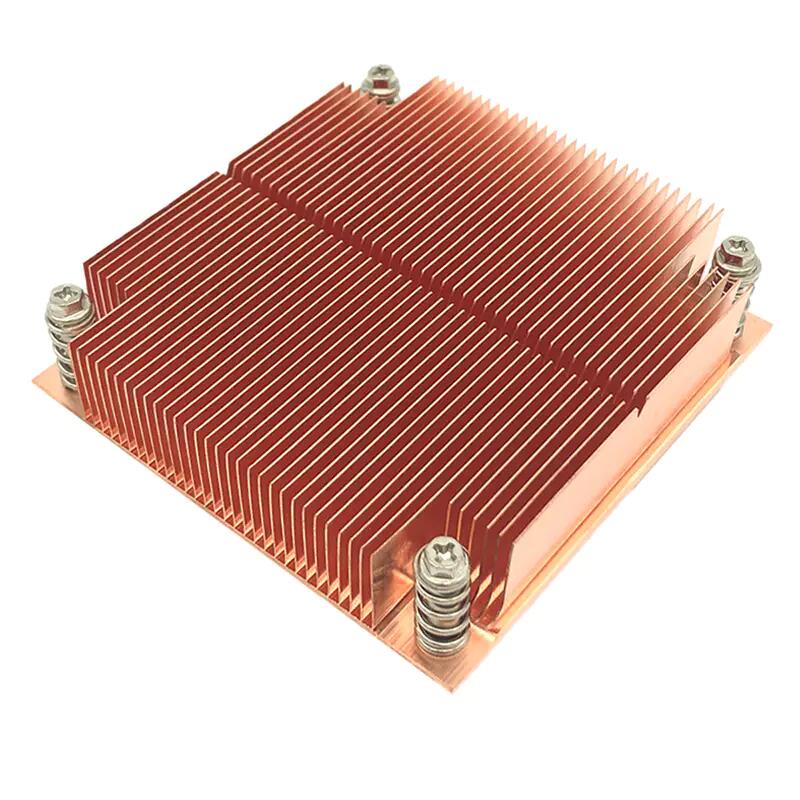

The skived fin heat sink is a type of heat dissipation device designed in a 'fin + baseplate' format, effectively increasing the heat dissipation area and enhancing heat dissipation performance. Typically made of aluminum, the skived fin heat sink efficiently dissipates heat generated by electrical components. In working environments, electrical equipment produces significant amounts of heat, which, if not dissipated promptly, can lead to equipment malfunctions and damage. The skived fin heat sink rapidly dissipates this heat, ensuring the normal operation of the equipment.

The benefits of using skived fin heat sinks produced through skiving technology encompass several aspects:

(1) Skived fin heat sinks feature a higher fin density, enhancing their heat dissipation performance.

(2) The fin height of skived fin heat sinks can reach up to 120mm, fully meeting the production requirements of most heat sinks.

(3) The fins of skived fin heat sinks can be made thinner, ranging from 0.05mm to 2mm, contributing to a lighter overall weight of the heat sink.

(4) As skived fins are directly formed from the original material, there is no loss in heat dissipation efficiency, achieving 100% of the original material's heat dissipation capability. Additionally, risks such as loosening or detachment are eliminated, improving the reliability of machine operation.

(5) Skived fin heat sinks exhibit high compatibility and offer significant potential for post-processing, allowing for further enhancements in heat dissipation performance through techniques like embedding copper tubes.

(6) With continuous improvements in the performance and efficiency of skiving machines and the refinement of skiving materials, large-scale production has become feasible.

Advantages of Skived Fin Heat Sinks:

(1) Skived fin heat sinks are produced by a single skiving process from an aluminum (or copper) sheet, resulting in a seamless integration of fins and baseplate without joints. This configuration facilitates highly efficient heat conduction.

(2) The skiving process enables the production of thinner and taller fins (even thinner than those of extruded aluminum profiles), leading to a higher fin density and subsequently, superior heat dissipation efficiency.

(3) Due to the integrated skiving process, skived fin heat sinks achieve a lighter weight for the same heat dissipation area, translating into lower material costs.

(4) Compared to extrusion processes, skiving offers fewer size constraints, allowing for wider and taller fins, ideal for dissipating heat from high-power chips.

(5) For small-batch, large-volume heat sinks, skiving technology utilizes sheet metal processing, eliminating the need for costly molds.

(6) In response to the increasing heat generation of modern chips, advancements in skiving technology and raw material processing, coupled with the integration of 1060 aluminum sheets and embedded heat pipes in the baseplate, have emerged as a significant highlight in large-scale thermal management assemblies.