In our current life, the application of laser instruments and equipme, laser skin beauty instrument, etc., which greatly facilitates our life.nt has been very extensive, in the industrial electronics applications including laser marking, laser cutting, laser welding, etc., in addition to the medical industry, the application of laser instruments and equipment is also very wide, such as oral laser treatment instrument, laser eyebrow washing instrument

Nokia announced a milestone on June 3 in Espoo, Finland, when its innovative 5G AirScale liquid cooled base station solution not only achieved the first commercial deployment worldwide, but also significantly helped Finnish mobile operator Elisa cut base station energy costs by 30% and significantly reduced CO2 emissions by around 80%. It demonstrates Nokia's strong commitment to promoting sustainable development and addressing climate change. This breakthrough technology, by using liquid cooling rather than traditional air cooling, effectively responds to the challenges of the surge in power consumption of base stations in the 5G era, because the power consumption of 5G base stations is 2-3 times that of the 4G era. The core advantage of liquid cooling technology is its efficient heat transfer performance, and the heat capacity of water is far greater than that of air, making the energy efficiency of liquid cooling systems far greater than that of traditional air cooling, thus significantly reducing energy consumption and carbon emissions.

In particular, Nokia's liquid-cooled base station design is not only quiet and maintenance-free, but also significantly optimised for a reduction of up to 50% in size and 30% in weight, saving operators significant operating costs and extending the service life of base station components. This series of advantages is not only a major contribution to the current 5G network construction, but also lays a solid foundation for the extensive application of liquid cooling technology in communications infrastructure, indicating that liquid cooling technology will become an important trend in the field of base station cooling in the future, opening up a new path for the green and sustainable development of the communications industry.

Liquid cooling heat dissipation

Liquid cooling heat dissipation is a kind of cooling technology suitable for high power electronic equipment, using the large specific heat capacity characteristics of liquid cooling medium to quickly take away the heat of the equipment.

At present, the application and development focus include single-phase liquid cooling, two-phase liquid cooling, submerged liquid cooling, spray liquid cooling and so on. The first two kinds of liquid cooling technology, the cooling medium does not directly contact the electronic device, the latter two kinds of liquid cooling technology use dielectric liquid, direct contact with the electronic device, the best cooling effect.

Single-phase liquid-cooled coolant is driven by a pump and flows in the channel to take away heat, the most common application is water-cooled plate, which is a more mature technology. The cost of water-cooled plate is mainly concentrated in materials, flow molding and welding.

The topological design of water-cooled plate runner and the integrated process of simple runner groove sealing and welding are the two leading directions that we know at present.

The flow path topology design, as explained by the Toyota researchers, aims to combine jet shock in the cooling plate with runoff based on an optimized post-branch cooling channel, ultimately removing most of the heat evenly with minimal pressure drop, without the need to install a large pump to increase the flow of coolant, resulting in energy waste.

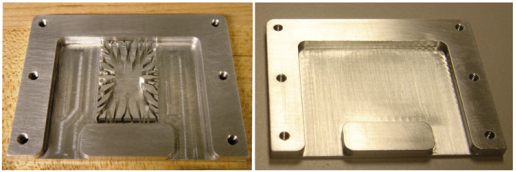

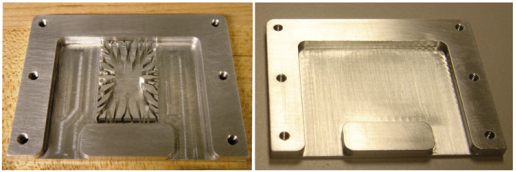

The following figure shows the prototype of liquid cooling plate designed by COMSOL Multiphysics software.

On the left is a prototype of an aluminum cooling plate with a layered microchannel topology; The picture on the right shows the prototype of aluminum heat dissipation plate without topology.

Now, we can also use AI computing technology to develop a topological design flow path liquid cooling plate with 20% higher cooling efficiency.

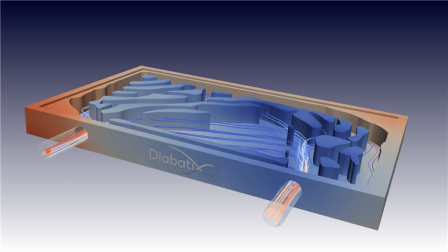

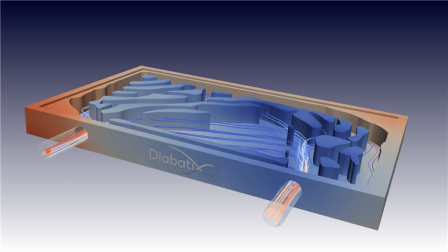

Diabatix topologically designs the flow channels of the liquid-cooled radiators with the help of AI drives. The design is optimized for uniform surface temperatures. The design method automatically takes into account flow limitations (velocity, pressure drop), thermal characteristics of the materials used, and manufacturing limitations (such as CNC milling). Efficiency gains of up to 20% can be achieved compared to conventional designs at the same flow rate.

Next, a brief introduction to two-phase liquid cooling. Two-phase liquid cooling is an efficient cooling technology that uses the latent heat of evaporation of the liquid medium (latent heat is much larger than the sensible heat of the single phase) to quickly take away heat.

Two-phase liquid cooling products we are most familiar with is the uniform temperature plate (Vapor Chamber), the uniform temperature plate can be combined with the cold row to make an internal circulation system, the liquid reflux does not need to be driven by pump pressure, under the action of vapor pressure or gravity or capillary force, to achieve the reflux internal circulation (closely related to the installation location).

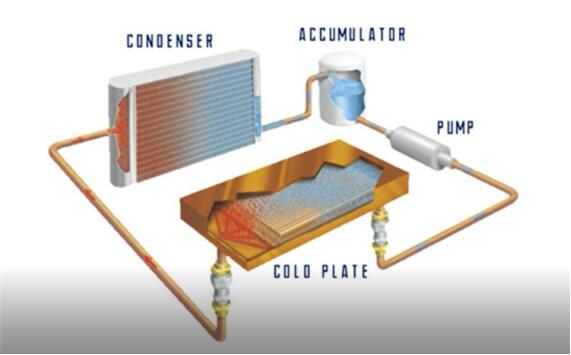

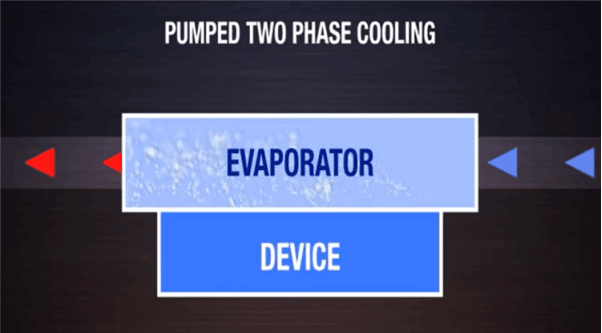

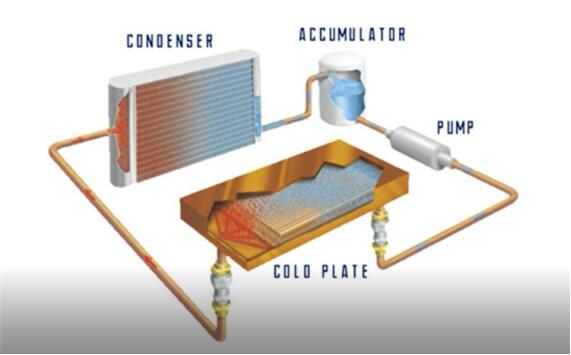

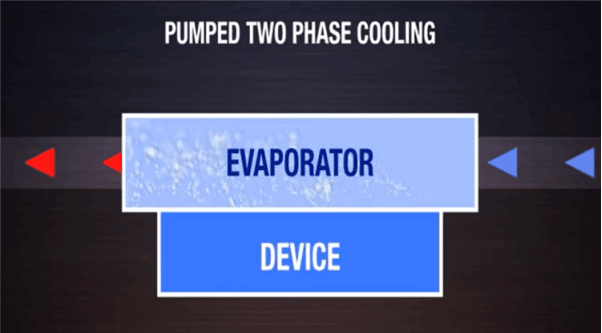

In addition to internal circulating two-phase liquid cooling, we can also add a magnetic pump with low power to achieve a pumping two-phase cooling system. Compared to single-phase liquid cooling, the pumped two-phase cooling technology can bring twice the cooling efficiency.

Schematic of ACT's pumped two-phase cooling system

The cooling medium of the pumped two-phase cooling system evaporates at the heat source, and the latent heat of evaporation quickly carries away the heat (Image: ACT)

The above briefly introduces the non-contact liquid cooling technology, whether single-phase liquid cooling, or two-phase liquid cooling, all need cold plates and pipelines to form a coolant circulation system. Contact liquid cooling, that is, submerged liquid cooling, where the electronic components of the circuit board are directly immersed in the dielectric coolant, is currently the most efficient cooling technology.

With the acceleration of 5G high-speed infrastructure network construction, the cooling demand trend of 5G base stations, cloud computing, edge computing and other data centers is bullish, and efficient and rapid cooling, reducing volume and weight, convenient deployment, and reducing operation and maintenance costs are the focus of the industry.

LORI as one of liquid cold plate manufacturers providing all around liquid cooling plate thermal solutions and we also provide you with the thermal heat sink design, structural design, pipework assembly design of liquid and water cooled plate and one-stop supplementary services.