In electronic equipment, heat sinks are crucial for dissipating heat generated inside the equipment, ensuring stable operation. While copper has better thermal conductivity, aluminum has become the mainstream choice for heat sinks. This article explores why aluminum is preferred over copper.

Thermal Conductivity and Heat Dissipation Efficiency

Copper does have superior thermal conductivity, about 1.69 times that of aluminum. This means copper can transfer heat faster under the same conditions. However, heat dissipation efficiency depends on multiple factors, including the heat dissipation area, method, and other physical properties of the material.

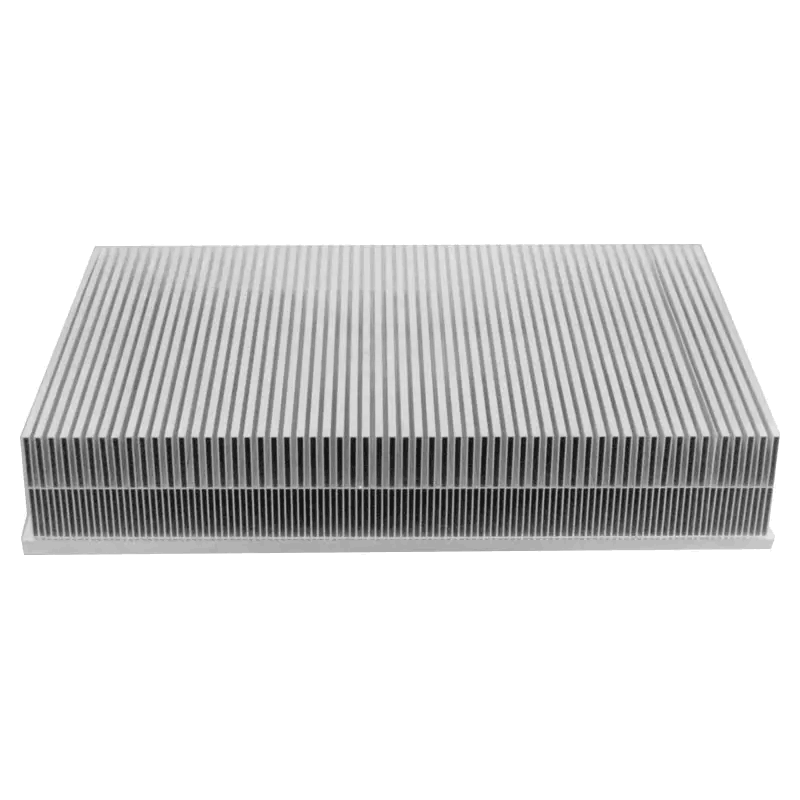

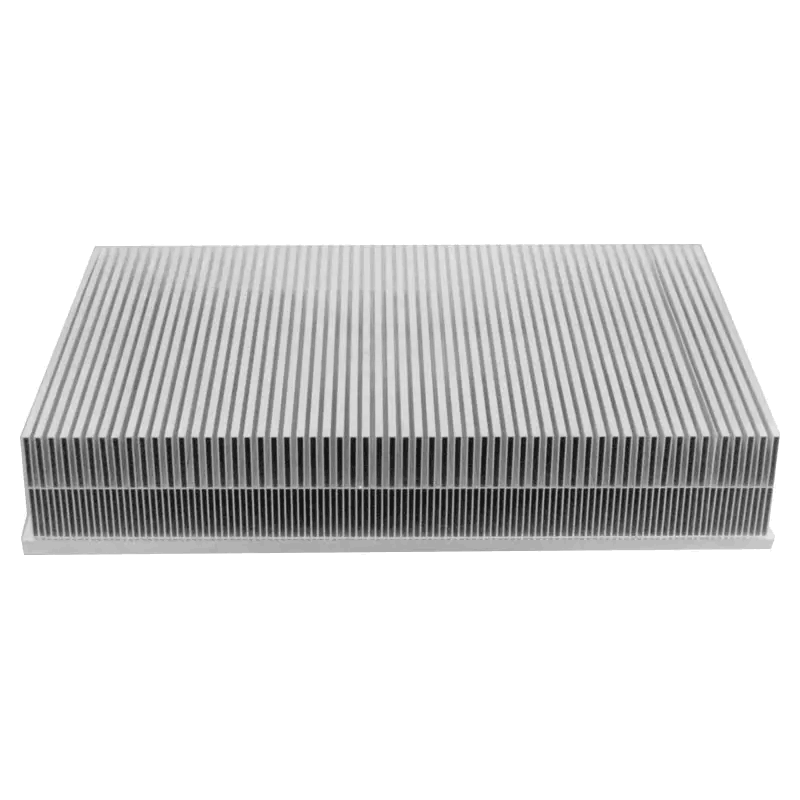

Although aluminum's thermal conductivity is slightly lower, its low density and lightweight nature allow aluminum heat sinks to be designed thinner while maintaining a large heat dissipation area. A larger heat dissipation area enhances heat dissipation efficiency, as more heat can be transferred to the air quickly. Therefore, despite copper's better thermal conductivity, aluminum heat sinks achieve efficient heat dissipation through optimized design.

Cost and Processability

Cost is a significant factor in choosing heat sink materials. Copper is much more expensive than aluminum. Using copper in mass production significantly increases manufacturing costs. Aluminum, with its lower cost and abundant availability, offers clear advantages. Additionally, aluminum is easier to cut, press, and weld, reducing processing difficulty and production costs further.

Corrosion Resistance and Service Life

Corrosion resistance and material longevity are crucial in selecting heat sink materials. Aluminum has excellent corrosion resistance, maintaining stable performance in various environmental conditions. While copper has some corrosion resistance, it is prone to oxidation and corrosion in high humidity or high salt environments, potentially shortening the heat sink's lifespan.

Practical Application Scenarios

Despite aluminum's dominance, copper is irreplaceable in certain applications. For example, CPU heat sinks operating at high frequencies may benefit from copper due to its faster heat transfer rate and higher corrosion resistance. Additionally, high-end heat dissipation products sometimes use copper-aluminum composites to leverage the benefits of both materials, achieving superior heat dissipation.

Conclusion

In summary, aluminum is preferred for heat sinks due to its good thermal conductivity, low cost, excellent processability, and superior corrosion resistance. These attributes allow aluminum heat sinks to be cost-effective and efficient. However, in specific scenarios, copper or copper-aluminum composites may be better suited. When choosing heat sink materials, consider the specific application needs and budget for the best results.