The pipe embedding technique is the most commonly used method for making water-cooled plates. This involves CNC milling grooves into an aluminum base plate, embedding copper pipes, and then using a hydraulic press to secure the bent copper pipes onto the aluminum base plate, followed by further processing into the final product.

The pipe embedding technique can be broadly classified into four forms:

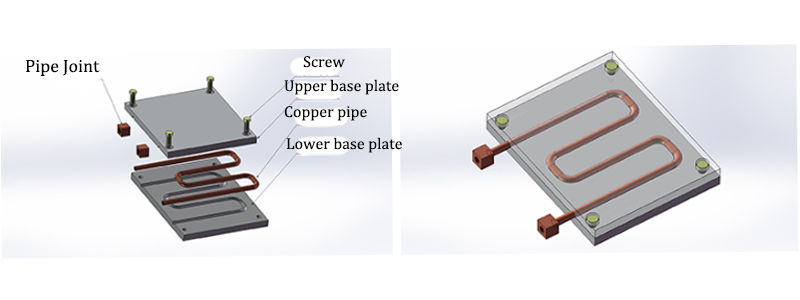

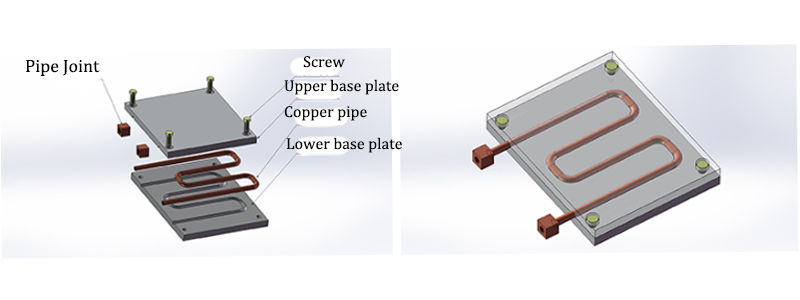

1. Shallow Embedding Technique: Suitable for single-sided heat source devices. The copper pipe and aluminum plate are press-fitted, and then CNC milled to ensure flatness. This method leverages the high thermal conductivity of copper to dissipate heat while using lightweight aluminum to reduce weight and control costs.

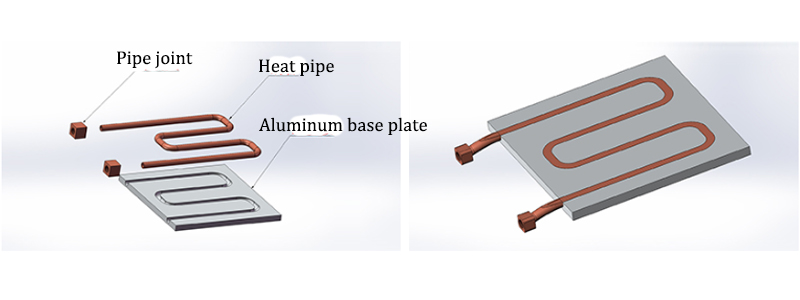

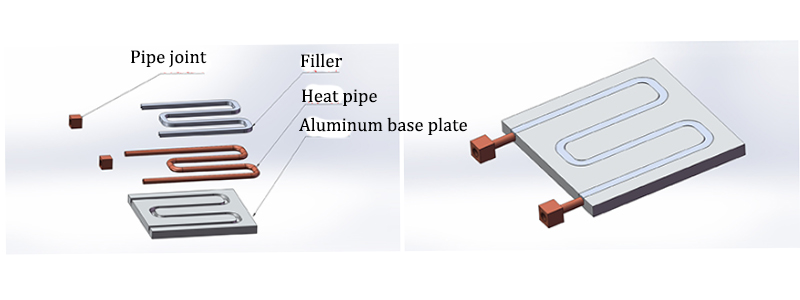

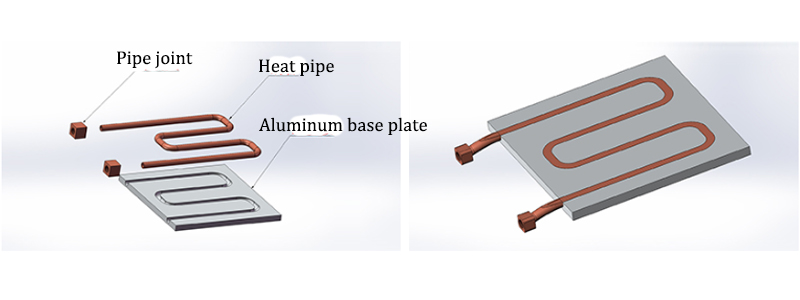

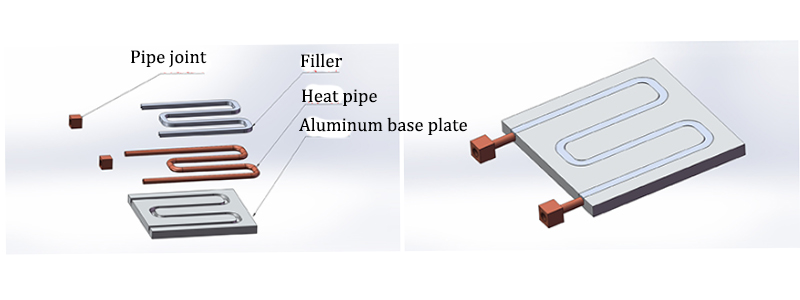

2. Deep Embedding Technique: Suitable for dual-sided heat source devices where temperature difference requirements are not high. It can also be used for single or dual-sided heat source devices. High thermal conductivity epoxy resin imported from the USA is used to fill gaps, and the copper pipe's thickness remains unaltered, providing filler protection that enhances application safety. This technique is especially suitable for cold plates using refrigerants as the medium.

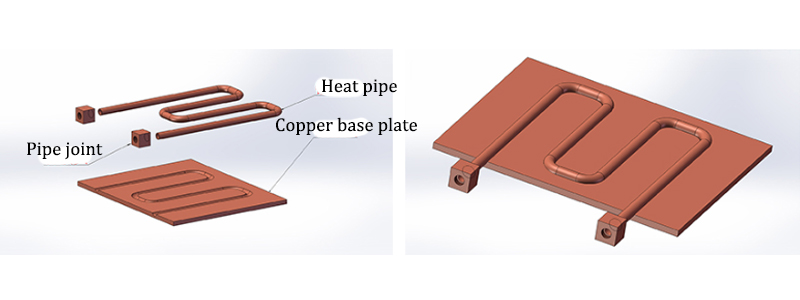

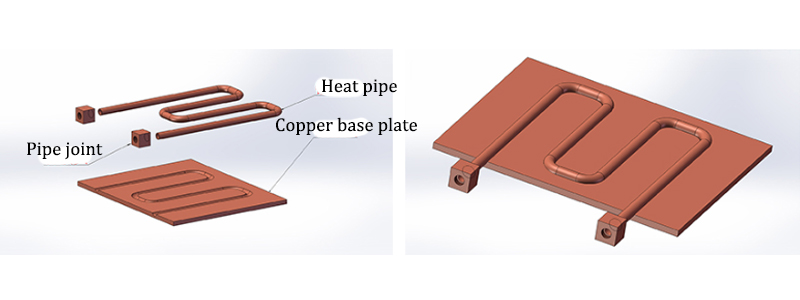

3. Welding Technique: Suitable for a combination of copper plates and copper pipes to reduce plate thickness and thus weight. It is also appropriate for cooling heat source devices in high-temperature environments, as brazing materials are more heat-resistant than epoxy resin.

4. Double-Sided Clamping Technique: Suitable for dual-sided heat source devices. This technique is simple and low-cost and can be adapted for aluminum base plates with aluminum, copper, or stainless steel pipes.