LED (Light Emitting Diode), light emitting diode, is a solid-state semiconductor device that converts electrical energy directly into light energy. The heart of the LED is a semiconductor chip, one end of the chip is attached to a bracket, is the negative electrode, the other end is connected to the positive electrode of the power supply, the entire chip is encapsulated by epoxy resin.

A semiconductor chip consists of two parts, one is a P-type semiconductor, in which holes dominate, and the other is an N-type semiconductor, on which are mainly electrons. But when the two semiconductors are connected, a "P-N junction" is formed between them. When the current is applied to the chip through the wire, the electrons are pushed to the P region, where the electrons are combined with the holes, and then the energy is emitted in the form of photons, which is the principle of LED light. The wavelength of light determines the color of light, which is determined by the material forming the P-N junction.

In the process of converting electrical energy into light energy, when the current flows through the LED components, the temperature of the PN junction will rise, forming the so-called luminous heat, that is, the higher the current, the higher the temperature, the higher the brightness of the light, many people may say here, since this is the case, why do you want to control the temperature of the LED?

To understand this problem, let's first look at how high temperatures can affect LED and LED lamps.

The effect of temperature on LED

①LED is mainly composed of support, silver glue, wafer, gold wire (copper wire), epoxy resin, which in addition to support and epoxy resin, the other three kinds of material damage can directly lead to LED stop working, and too high temperature, just is the above three kinds of materials, in a high temperature environment LED light decay will increase, reduce the service life of LED, More can even burn the gold wire (copper wire) in an instant, leading to direct damage to the LED.

②Single LED can not directly meet the needs of use, often accompanied by LED power supply (drive), the power supply itself is a heating body, it has its own temperature requirements, if the temperature is too high, it will cause power failure or even damage, resulting in LED lamps can not work normally.

Therefore, it is urgent to solve the temperature problem of LED and LED lamps, that is, heat dissipation.

Principle of heat dissipation

Heat dissipation in the traditional sense is the so-called transfer of heat, and the principle of heat transfer has the following three points:

1.conduction

As we all know, heat can be conducted through the medium, it can be transferred from the temperature is too high to the temperature is too low, in this case, then the conductivity of the material, the thermal resistance caused by the structure of the heat dissipator and the shape and size may interfere with the heat conduction.

2.radiation

High school physics teachers tell us that heat is going up, in fact, this is the so-called radiation, it is very limited to the surrounding environment and the material of the radiation body itself.

3.convection

People who buy buildings should have heard the concept of a floor, sales will generally say that such a building is very cool, indeed, the so-called convection is through the flow of gas or liquid to heat, its heat dissipation speed generally depends on the speed of the flow, if you want to achieve on the lamp body is difficult (consider waterproof, safety and other factors), However, it is not without specific reference to the products shown below.

The above three points of heat dissipation, now the most used in lamps is heat conduction, and this is also the topic we focus on today.

Heat conduction

After reading the above text, you should notice that there are three points that affect heat conduction, material, structure and size.

1.Materials

When it comes to materials, we have to be composed of LED lamps, the first one of the most common LED lamps is composed of a heat sink (lamp body), LED, substrate, power drive, optical components. Among them, the heating body has LED and drive two, and the cooling body has a heat sink, a substrate, or an aluminum optical component (the heat transfer amount is almost negligible).

heat sink

The heat sink of LED lamps is generally made of aluminum, which is divided into two categories, tensile aluminum based on aluminum such as AL6060, and die-cast aluminum based on ADC12. Among them, the thermal conductivity of ADC12 is 96.7w/m ° C, AL6060 aluminum is 198~250w/m ° C, the latter is better than the former in thermal conductivity, see here some people may ask, since AL6060 and other aluminum thermal conductivity is so good, why there will be ADC12?

①ADC12 die-cast aluminum, which is fast in mass production, can meet the general requirements of the design aesthetic (almost all the shapes you think of can be presented), but because of the low change, the design mold cost is high, generally used in the size is not very large, do not need to modify the product, the same because it is relatively cheap, so it has long occupied the shell market.

②Tensile aluminum, strong thermal conductivity, low mold cost is generally one-tenth of the die casting mold, the length change is also very flexible, the processing mass production is fast, but it can not fully occupy the shell market reasons for the following: insufficient hardness, easy to deform, the appearance of the basic can only be stretched type, less change, can not meet the market appearance requirements.

Combining the above two points, it can be concluded that heat dissipation tensile aluminum is better than die-cast aluminum, and the appearance practicality of the latter is better than the former, depending on the cost requirements and appearance requirements of the design.

substrate

In addition to the shell, the substrate is also one of the important cooling body, the heat dissipation substrate commonly used in LED lamps on the market has copper substrate, aluminum substrate, of which the thermal conductivity copper substrate is better than the aluminum substrate, but the price is relatively high, a large part of the designer or enterprise will choose aluminum substrate as the heat dissipation plate.

2.Structure

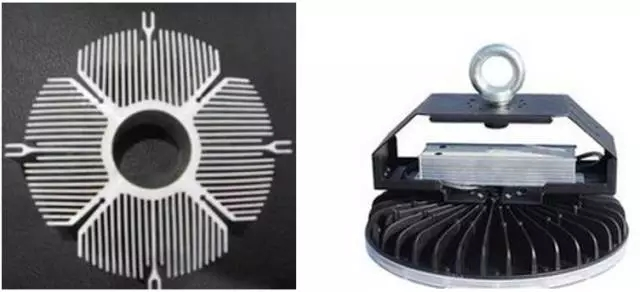

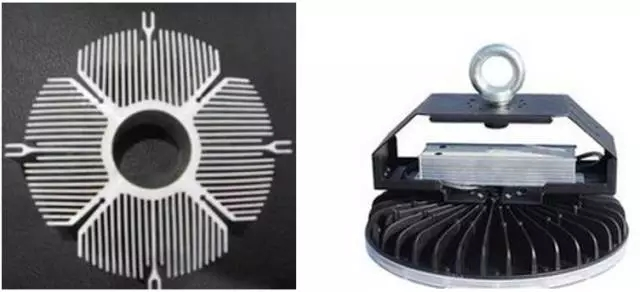

① The design of the fins in the following figure can be used in appearance.

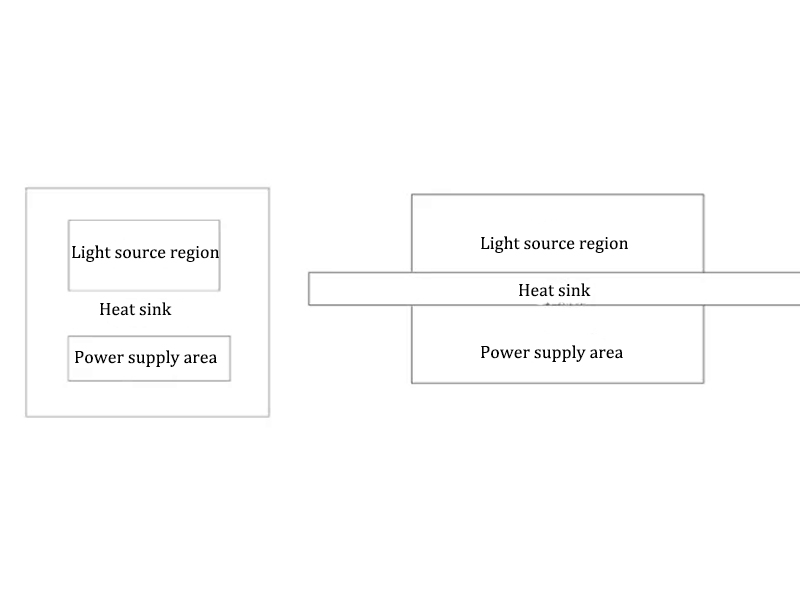

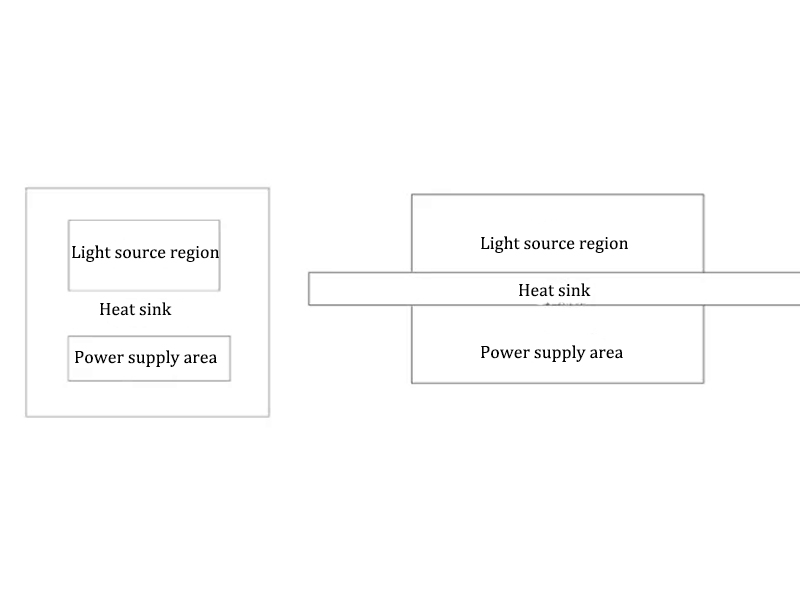

② In the early stage of design, we should think about the placement of electronic components to avoid the common heat source situation in the following figures.

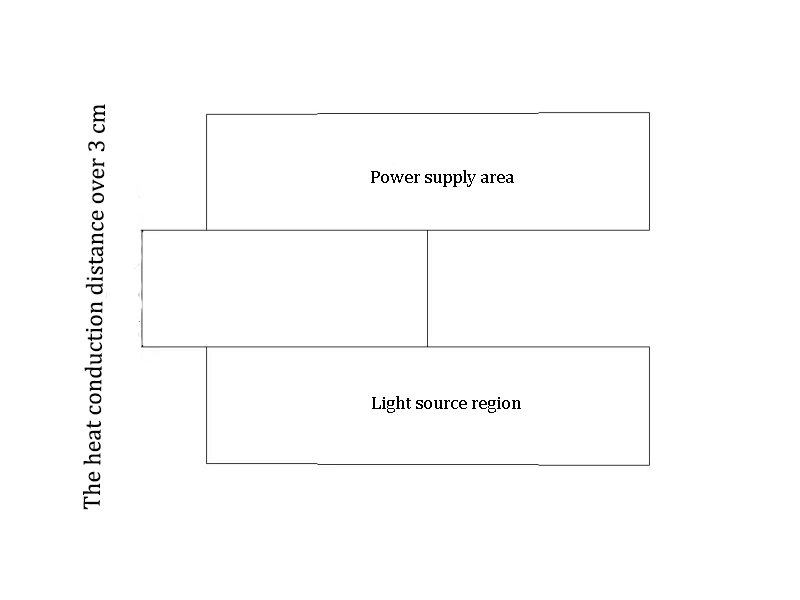

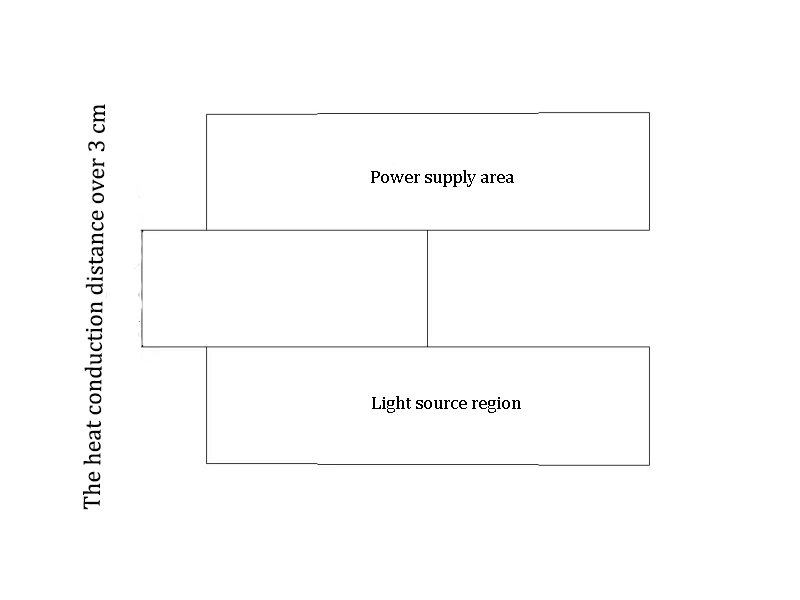

③ With the permission of the structure, it is best not to fix the position of the power supply to the light source, because according to the principle of heat circulation, the heat is going up, and in the case of no way to control it, it is best to reserve the conduction distance to more than 3CM (as for why, please Google the relevant knowledge of heat conduction). The design plan is shown below.

3.Dimensions

This will not be detailed, such as a square meter of material derived 1W heat, with a square meter of material derived 100W heat, this concept is very clear, there is no need to elaborate, here can only be recommended, in a reasonable range of the selection of reasonable size.

Misunderstanding of heat dissipation

Reading the above information, many people should understand that thermal conductivity is crucial for the heat dissipation of lamps, so many people will choose better heat dissipation materials, so superstitious in those so-called high price, not verified by the multi-party high-tech materials, in fact, there are experiments, with ordinary aluminum heat dissipation, after many tests, The temperature of heat sink is only 3-5° higher than some so-called high-tech heat dissipation materials, that is, if you can really use a material with excellent thermal conductivity, in the case of zero thermal resistance, you can only reduce the temperature by 3-5°, but the cost is another story.

In addition to the material, the heat pipe above there are also a lot of misunderstandings, first of all to say what is the heat pipe, the heat pipe (called heat pipe) is a special material with rapid temperature equalization characteristics, which is empty metal tube body, so that it has the characteristics of light weight, and its rapid temperature equalization characteristics, so that it has excellent thermal superconductivity; The application of heat pipes is quite wide, the earliest used in the aerospace field, now has been widely used in all kinds of heat exchangers, coolers, natural geothermal reference, etc., as a rapid heat conduction role, it is the most common and efficient heat conduction (non-heat dissipation) components in today's electronic product heat dissipation devices.

This introduction sounds very tall, but the heat derived from the heat sink eventually needs to be carried away by air convection, if there is no support of the heat fin, the heat pipe will soon reach a thermal balance, the temperature rises with the heat sink, it is not much sense, and the fins on the heat pipe are added, and the fins are eventually used to dissipate heat. Moreover, the contact point between the fin and the heat pipe is not as good as other ways of contact, which will also lead to an increase in cost, and the heat dissipation effect has not been improved. Therefore, when using heat pipes, try to consider their structural rationality and can not be used blindly.

Heat dissipation three points, conduction, convection, radiation, which conduction and convection I have explained, next talk about radiation, in fact, this is not much significance for the heat dissipation of lamps, but a lot of people will listen to those manufacturers say what nanoradiation materials, in fact, this is really negligible for lamps. Why? First of all, for the lamp, the temperature range is about 50-80°, and in this case, even if the radiation material reaches the radiation capacity of blackbody radiation, it can also play a maximum of a few percent of the heat dissipation, and the coating itself is an obstacle to thermal conductivity, thus affecting the heat dissipation of the lamp.