Skiving heatsink with heatpipe featues and benifits as below

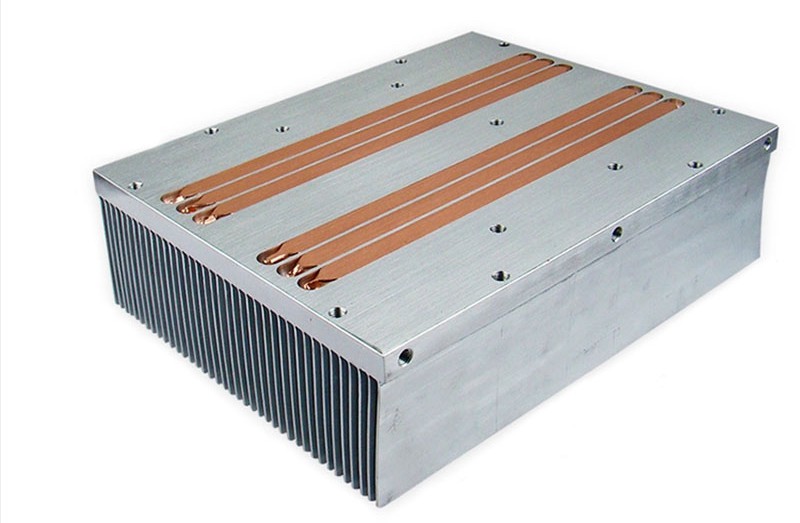

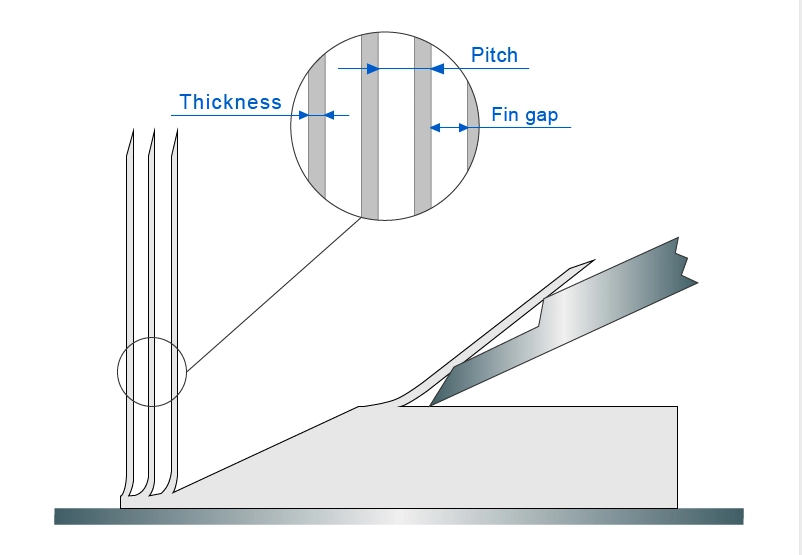

Skiving heatsink use a special sheet, with the dedicated chipping equipment(skiving precision cutting technology) to required chainrings, Ultra-small spacing, Multiple ultra-high heat sink body structure, heat sink efficiency is two times than traditional style due to the chainrings combined with base, and high purity materials.

1. Skiving heatsink technology leading the heat innovation innovation high density ,high thermal performance, high aspect ratio, excellent performance.

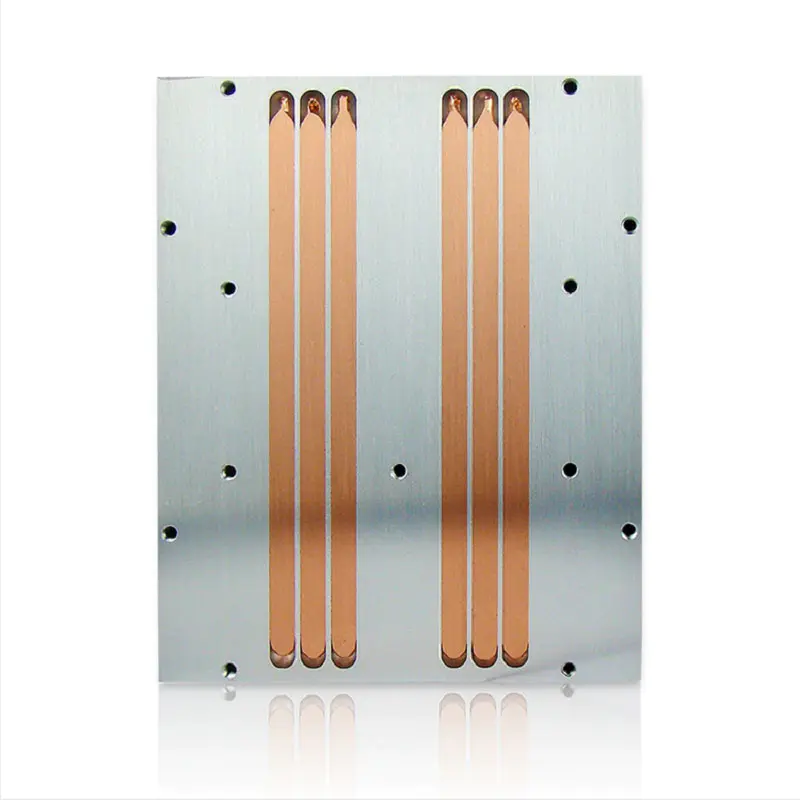

2. Skiving heatsink soldering with heatpipe, it owned both the advantage of Al Material and heat pipe ---Good thermal conductivity

3. Customized design size is 200*159*59mm, other customized size is accepted.

4. Factory price and Industrial high quality heat sink.

Skiving heatsink with heatpipe has heat stable, secure, reliable, and can effectively protect the heating elements extend its life.

The main products of skiving heatsink with heatpipe are: high power heat sink, IGBT heatsink, electronic components / chips / CPU cooler, different power levels to meet the cooling needs, to achieve the best cost-effective price.