SVG is a high-reliability, high-efficiency, and pollution-free high-voltage, high-power power quality improvement product. The main role of the reactive power compensation device in the power supply system is to improve the power factor of the grid, reduce power losses on the transformer side and transmission lines, and enhance the power system's supply efficiency, thereby improving the power network's supply environment.

Heat Dissipation Issues of SVG

When an SVG operates, power loss generates heat, primarily from the IGBT power modules. As IGBT chip technology advances, the size of IGBTs has decreased, but their power consumption has increased significantly, resulting in much higher heat flux density. Excessive temperature can shorten the lifespan of components and, in severe cases, even cause them to burn out. This is a major factor limiting the current and voltage capacity of power electronic devices. Although the failure of electronic components can be influenced by various factors, temperature remains the primary factor. Therefore, it is crucial to address the cooling issues of SVGs during use to extend their lifespan and reduce failure rates.

Introduction to SVG Water Cooling System

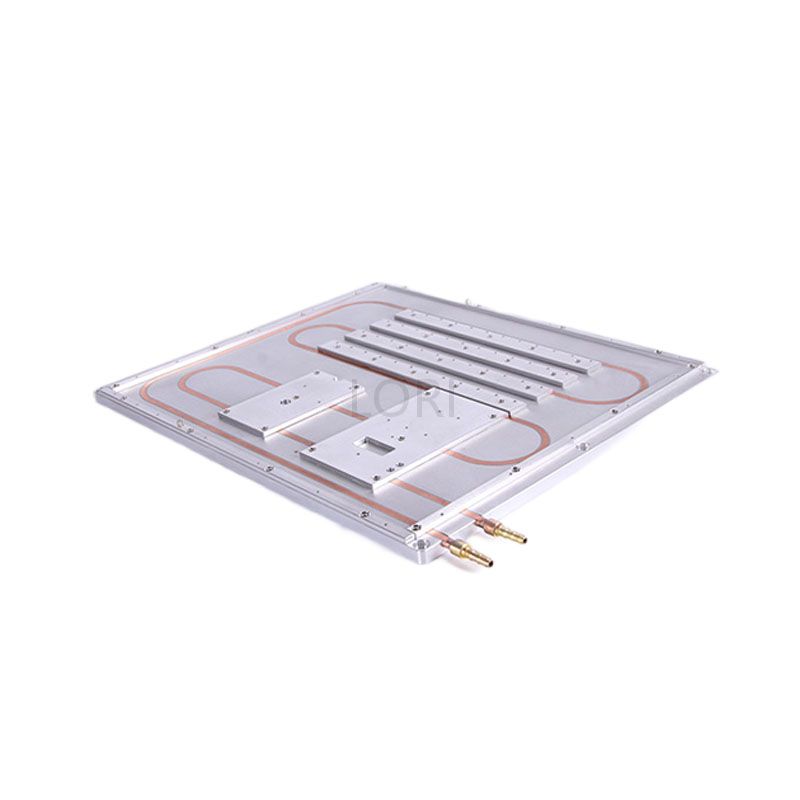

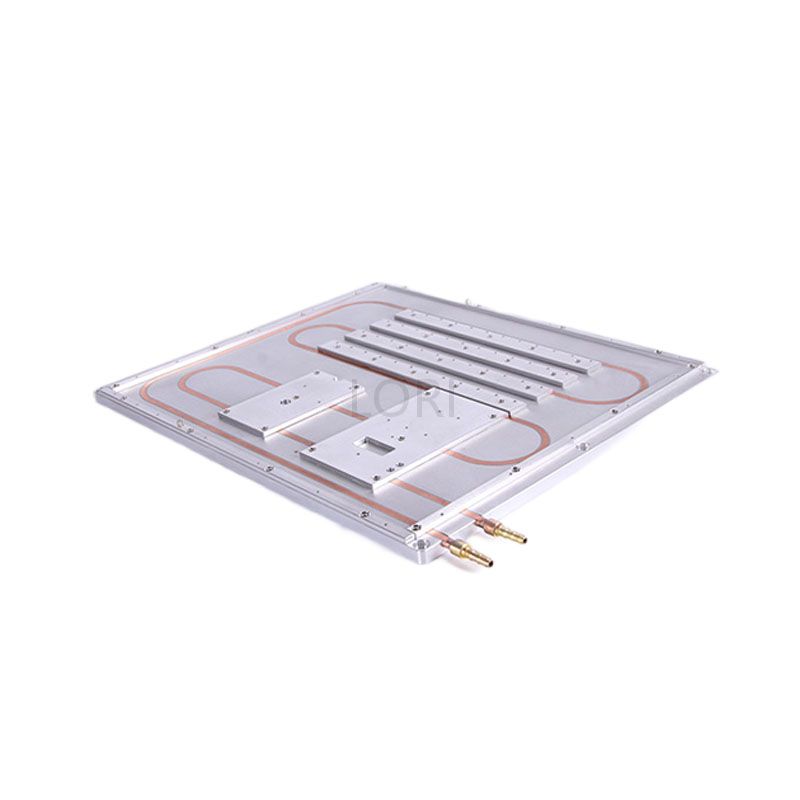

The SVG water cooling system mainly consists of two parts: the cooling system and the control system. The cooling system includes the main circulation loop, water-to-air heat exchanger, and water-cooled plates. The main circulation loop comprises vertical circulation pumps and pipelines, providing the necessary power for the closed-loop circulating fluid. The water-to-air heat exchanger removes heat from the system. The water-cooled plates absorb heat from SVG components and other semiconductor devices during operation, transferring this heat to the air-cooled heat exchanger, forming a closed-loop cooling system.

Compared to air cooling, liquid cooling has a thermal conductivity that is two orders of magnitude higher. When power density is very high, liquid cooling is a practical method for temperature control. Given the trend of SVGs towards miniaturization, increasing power, and higher heat dissipation per unit, the advantages of liquid cooling are evident.

To better address the heat dissipation issues of SVG devices, the Lori R&D team balanced the advantages and disadvantages of air and liquid cooling and developed a liquid cooling system tailored for high-heat-flux-density SVG devices.

Technical Advantages of SVG Water Cooling System

1. Design of the Cooling Liquid Circulation Unit: Only a standardized water-cooled plate that fits the IGBT is installed inside the electronic device, effectively removing the heat generated by the device.

- The internal circulation pipes are integrated into the water-cooled plate, simplifying the structure and enhancing the system's safety and stability.

- It facilitates the assembly of electronic devices and maintenance of the cooling system, improves heat dissipation efficiency, and reduces noise and vibration inside the electronic device.

- The design of the cooling unit can meet different layout requirements and offers good portability.

2. Cooling Liquid Supply Unit: The integrated heating device effectively addresses condensation issues in the pipes.

3. Control System: The system monitors key information such as the flow rate, temperature, and pressure of the inlet and outlet cooling liquid, as well as the device temperature, to control the operation of the cooling device, circulation pump, and make-up water pump, maintaining orderly operation of the entire cooling system.