The skived fin heat sink is a highly efficient thermal management solution widely used in electronic devices and high-power applications. Its primary function is to effectively dissipate heat by increasing the surface area in contact with air.The fins of skived fin heat sinks are usually manufactured using a skiving process, where the shape and arrangement optimize airflow, thereby improving heat exchange capacity.

Materials for Skived Fin Heat Sink

Skived fin heat sinks are typically made from the following materials:

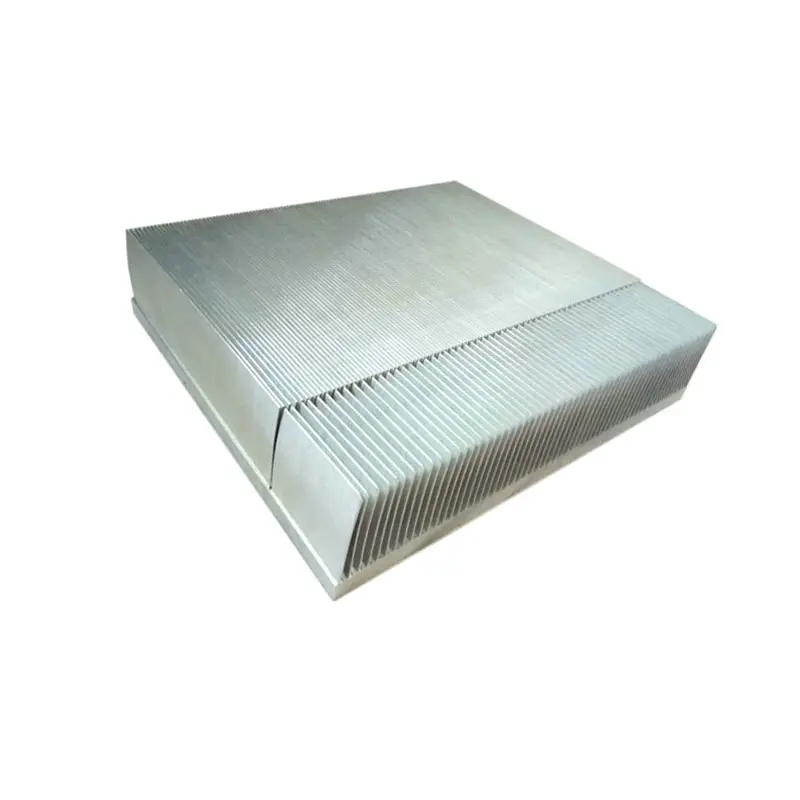

Aluminum Alloys: Lightweight and good thermal conductivity, suitable for most electronic devices.

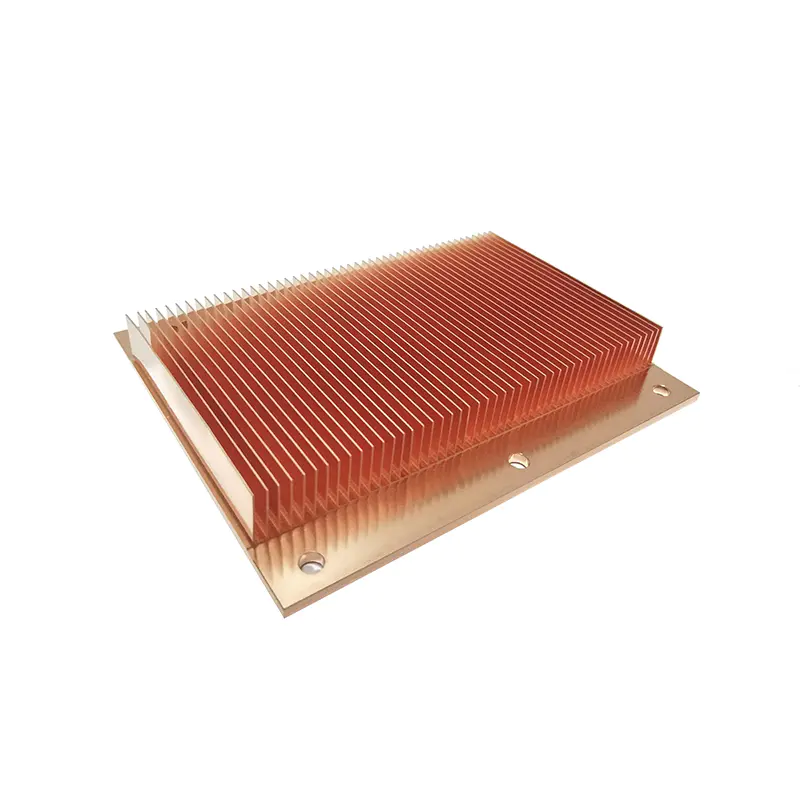

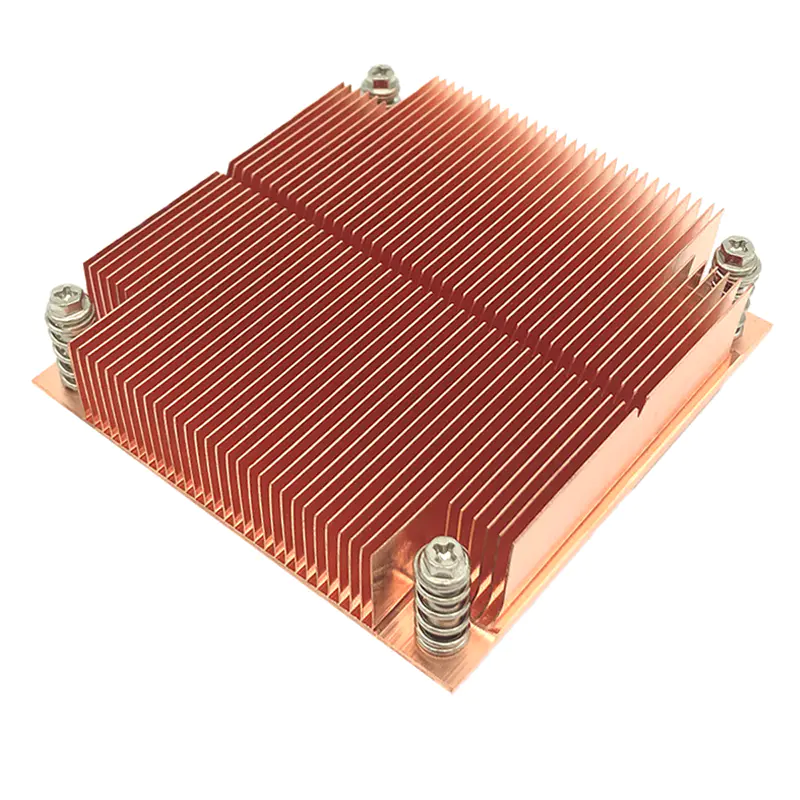

Copper: Superior thermal conductivity, ideal for applications with extreme heat dissipation requirements.

Composite Materials: In specific applications, combining different materials achieves better thermal performance.

The process of skiving a heat sink mainly includes the following steps:

Material Selection: Typically, aluminum or copper is chosen due to its excellent thermal conductivity and machinability.

Skiving Process: CNC milling machines or skiving machines are used to shape metal sheets into the desired fin structure.

Forming and Assembly: After skiving, the heat sink is formed and combined with the base to ensure good contact.

Surface Treatment: Anodizing or coating may be applied to enhance corrosion resistance and thermal performance.

Applications of Skived Fin Heat Sink

Skived fin heat sinks have a wide range of applications, including:

Computer Cooling: Used for processors and graphics cards to ensure stable operation under heavy loads.

LED Lighting: Provides thermal management solutions for high-power LED lights, extending their lifespan.

Power Modules: Enhances efficiency and safety in power conversion and storage devices.

As one of skived fin heat sink manufacturers, Lori adopts precision skived fins process manufacturing customized copper and aluminum skived fin heat sink.These Heat sinks can dissipate heat for the equipment with higher heat dissipation efficiency, thereby increasing the service life of the equipment.