A heat pipe is an efficient thermal conduction device whose capillary core structure directly determines the heat pipe's performance and its applicable scenarios. This article mainly introduces several common types of capillary core structures in heat pipes.

A heat pipe transfers heat by using the phase change of the working fluid inside it, and it has the following basic characteristics:

1. Very high thermal conductivity

2. Excellent temperature uniformity

3. Reversibility of heat flow direction

4. Thermal diode and thermal switch properties

5. Environmental adaptability

The thermal switch property means that a heat pipe can be designed as a unidirectional thermal conductor; for example, it works when the temperature of section A is higher than section B, and it does not work when the temperature of section A is lower than section B.

The working principle of oil pipelines and heat pipes buried in permafrost utilizes the heat pipe's switch property. In winter, the temperature underground is higher than the air temperature, causing the heat pipe to operate and dissipate the heat from the permafrost into the air, making the permafrost temperature lower and more stable. In summer, when the air temperature is higher, the heat pipe does not work.

This is also a gravity heat pipe with a smooth inner wall and no capillary structure. Liquid return relies solely on the gravity of the working fluid, which has unidirectional properties.

In most electronic device applications, heat pipes do not have a fixed direction, so they need to adapt to fluid return in all directions. In such cases, the capillary structure on the inner wall of the pipe becomes very important. The capillary structure must transport the working fluid against gravity and ensure that liquid can quickly return to the evaporation end from any condensation section.

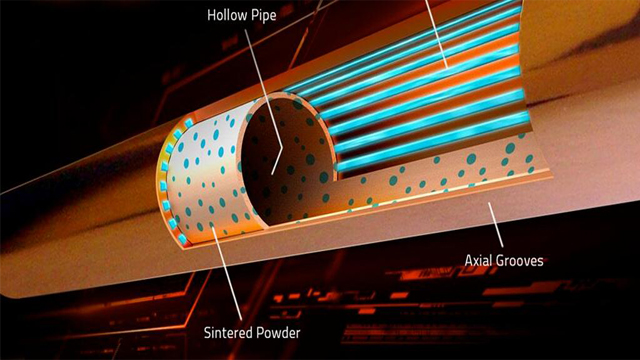

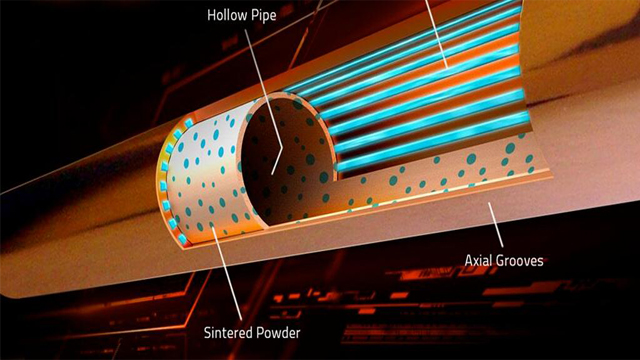

According to the needs of different scenarios and considering manufacturing costs, there are currently three main types of capillary structures:

1. Powder Sintered Structure (Powder)

Looking at the physical dismantling diagram below, you might think it is very soft, but in reality, this capillary core is neither soft nor loose but very firm. This is because it is made of copper powder that has been heated to a high temperature, restoring the original hardness of the metal after cooling. In fact, the process of making such a heat pipe is relatively complex. First, a cylindrical mold is placed in the center of the copper tube, then loose copper powder is poured in and vibrated to achieve a certain density. The product is then heated in a reducing atmosphere furnace to a certain temperature. Before the copper powder completely melts, the edges of the copper powder particles first melt and bond with the surrounding copper powder and the wall of the copper tube, forming the hollow structure you see now. The sintering temperature and holding time need to be appropriately matched to ensure bonding strength without melting the copper powder particles. Currently, this process is very mature, and the cost has significantly decreased, making it the most commonly used capillary structure type.

The methods for producing copper powder mainly include electrolytic, water atomization, and reduction methods. Electrolytic copper powder has a branched microscopic shape and features such as a well-developed surface, high purity, and good forming properties, but its production is energy-intensive, costly, and environmentally polluting. Water atomization method is more commonly used now. Currently, the widely adopted water atomization + reduction method (now AOR method) produces copper powder with modified surface, coral-like microscopic shape, well-developed surface, and good forming properties. It has a low bulk density (usually 1.5–3.0 g/cm³) like electrolytic copper powder, but with better flowability (usually less than 35s/50g), and stable process performance, thus replacing most electrolytic copper powder.

2. Groove Structure (Groove)

The groove structure has also been used for quite some time. From the diagram, we can see that the pipe wall is not smooth like that of the sintered copper tube but has a series of fine grooves along the direction of the copper tube's stretch. These grooves provide the capillary force in the heat pipe. The returning liquid quickly conducts through these grooves in the heat pipe. Obviously, the finer the grooves, the better the capillary force, but the material manufacturing cost will also increase. From the perspective of heat pipe production cost, the process of this type of heat pipe is relatively simple, with fewer steps as it does not require powder filling, resulting in lower manufacturing costs. The use of this capillary structure also needs to consider the direction of gravity. Groove capillarity is significantly affected by gravity. Generally, the best design is in the direction of liquid return. Therefore, theoretically, its cooling efficiency is not as high as that of the sintered copper powder structure.

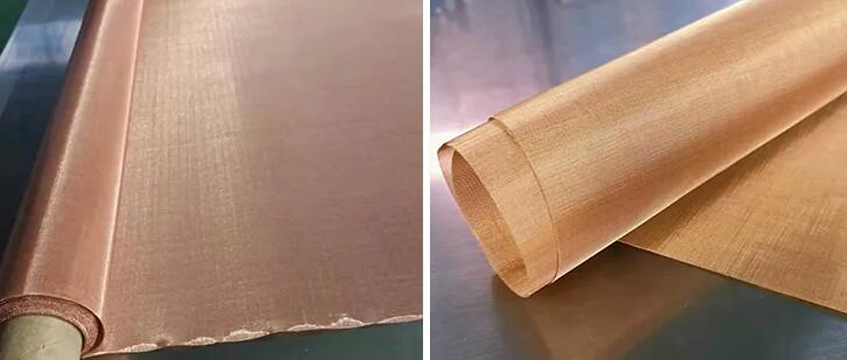

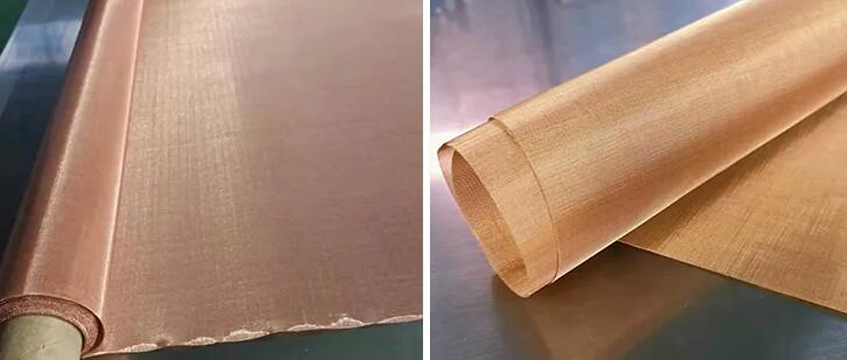

3. Metal Mesh (Mesh)

This structure is also quite common now. Like sintered powder, metal mesh also provides capillary force. This woven mesh, with the metal wires crossing and overlapping, forms pores that have capillary force and can overcome gravity to achieve rapid fluid transport. However, its capillary performance is not as good as that of sintered powder capillary cores. Copper wire mesh used for capillary structures is usuallyspecified by mesh count, with common specifications being 100 mesh, 200 mesh, 300 mesh, etc.

4. Composite Structure (Complex)

Given the advantages and disadvantages of the above structures, composite pipe structures that combine different types are also used. For example, copper powder + copper mesh, grooves + copper mesh, etc. For long-distance fluid transport, one or more metal woven wires can also be sintered on the surface of the powder or mesh to further increase the return speed and improve the return path.