NVIDIA's new generation of GB300AI servers will use the “Blackwell Ultra” architecture, due to the significant increase in performance, resulting in a significant increase in power consumption, will cancel the fan air cooling version and use the full liquid cooling solution, the full use of liquid cooling systems and to “liquid-to-liquid” mode, and the GB300 CPU and GPU will switch to a socket design, the demand for liquid cooling snap-in connectors will double. GB300 CPUs and GPUs will switch to socket design, which will exponentially increase the demand for liquid cooling quick-connect couplings. GB300 liquid cooling quick-connect couplings are required for 1 GB200 server cabinet, and it is expected that the number of liquid cooling quick-connect couplings required for 300 cabinets can reach 600, which will usher in an exponential growth of liquid cooling quick-connect couplings market.

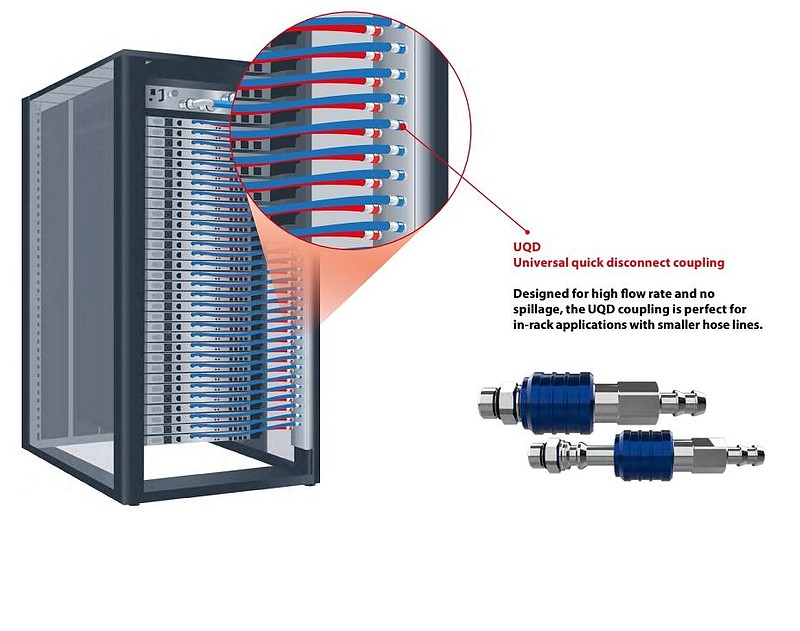

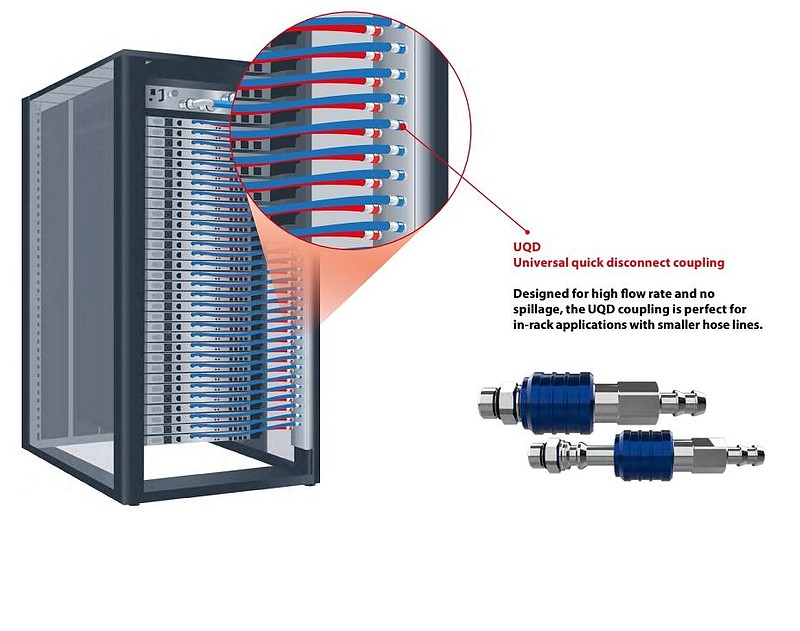

What is a universal quick disconnect?

Universal quick disconnect (UQD), also known as quick disconnect (QD), are used in computers or servers with liquid-cooling systems, and are one of the key components of liquid-cooling systems.UQDs have become the core components of liquid-cooling systems in data centers due to their high efficiency, safety, reliability and other characteristics.

UQD series quick couplings are a global open standard developed by the Open Compute Project (OCP) to achieve leak-free and fast switching of liquid cooling system connectors in data centers. The design concept is to provide a coupler solution that can be connected quickly and without leakage, specifically serving data centers, supercomputers, Internet switches and other scenarios that require liquid-cooling technology to process.

Features of UQD

UQD's leak-free, high-flow, low resistance, hot-swappable features are key to efficient data center operation and maintenance.

Safe and leak-free: critical to the normal operation of a liquid cooling system, as electronic components are close to the coolant circulation system and can easily be damaged or malfunction due to leakage.

High flow rate and low flow resistance: Ensures smooth flow of coolant through the system for efficient heat exchange, which helps maintain normal temperature of servers and other equipment during high power operation, ensuring performance and stability of the equipment.

Supports hot-swapping: allows connection or disconnection operations without stopping system operation, which is important for data centers that require uninterrupted operation.

UQD Application Scenarios

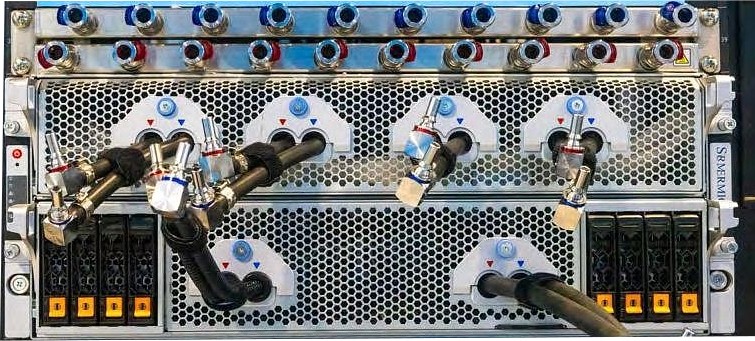

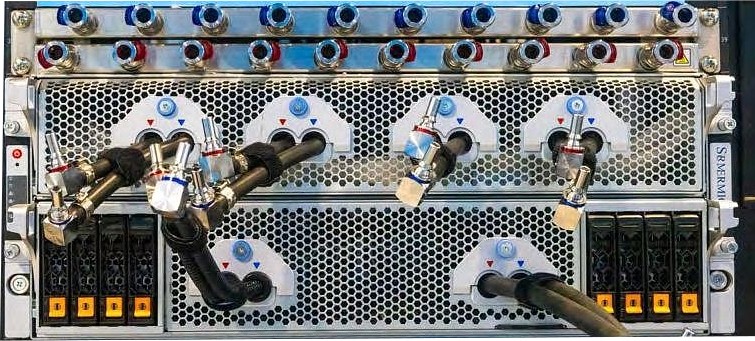

1.Board Level Liquid cooling Heat Dissipation

In high power density servers, the UQD connector connects the cold plate and the manifold to transfer the heat generated by the chip through the coolant to achieve efficient heat exchange. liquid cooling cold plate is the heat dissipation equipment directly contacting with server boards, and it is also the smallest unit of heat dissipation in data centers. Server liquid cooling cold plate includes liquid inlet connector, liquid outlet connector, upper cover plate and bottom plate, which are connected by vacuum brazing process to form a sealed liquid heat transfer cavity, and inside the cavity, liquid-sharing cavities and infusion grooves of different widths are set up according to the location of the chip and heat dissipation needs to realize the throttling control of the liquid flow and increase the perturbation, enhance the local heat dissipation capacity of the cold plate, and eliminate hotspots and heat dissipation bottlenecks caused by the high-power chips. Eliminate hot spots caused by high power chips.

2.Rack-level liquid cooling system

Inside the data center, information technology equipment is usually configured in accordance with rack units. Racks serve as the infrastructure for storing various types of information equipment within the data center, including but not limited to servers, storage devices, network switches and other key components. While board-level cooling is responsible for exporting the heat generated by individual IT equipment first, the entire rack is tasked with centralizing and efficiently transferring this heat to the external environment. The core components of a liquid cooling system at the rack level include key components such as inlet and return water distributors (manifolds), monitoring units, temperature sensors, solenoid valves, and check valves. The inlet and outlet Manifolds are connected externally to the liquid cooling distribution unit at the server room level, and internally to the inlet and outlet fittings of the liquid cooling plate through quick connectors, and the heat of the system is transferred to the outside of the rack through the Manifolds.

In recent years, the penetration of liquid cooling servers in major data centers has continued to increase, for example, shipments of NVIDIA's Blackwell series of chips have increased, driving market demand for liquid-cooling technology. As a manufacturer and supplier of liquid cooling components for data centers, Lori's liquid cooling quick disconnects are tested and certified to ensure that liquid cooling systems are free from the risk of leakage and seepage.