Microchannel liquid cooling technology is an innovativecooling solution designed to address the thermal management challenges in small electronic devices. As chip functionality continues to increase, heat dissipation issues have become more prominent, especially in devices with limited size, where traditional heat sinks fail to meet the demand. The latest advancements in microchannel liquid cooling technology bring hope for solving this problem.

Compared to air, liquids have a heat transfer efficiency that is 50 to 1000 times higher. However, the infrastructure required for traditional liquid cooling systems is too bulky for small Internet of Things (IoT) devices. Thanks to rapid advancements in precision manufacturing technology, liquid heat sinks can now be significantly reduced in size. Some cold plates are as small as 2x2 centimeters but have a heat dissipation power of up to 1000 watts per square centimeter.

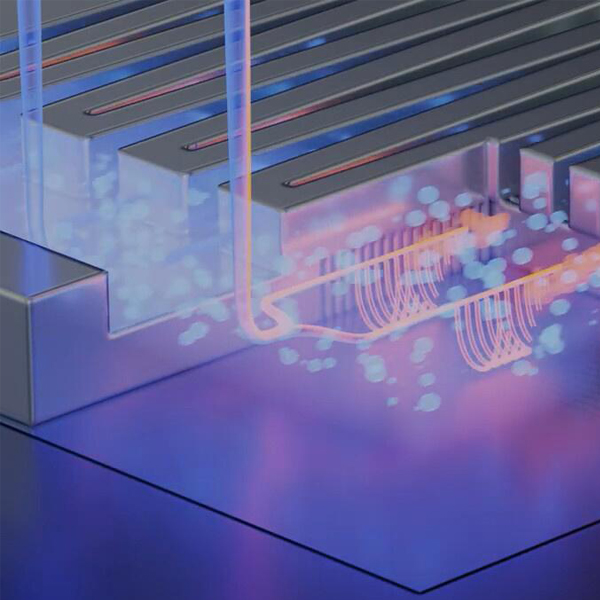

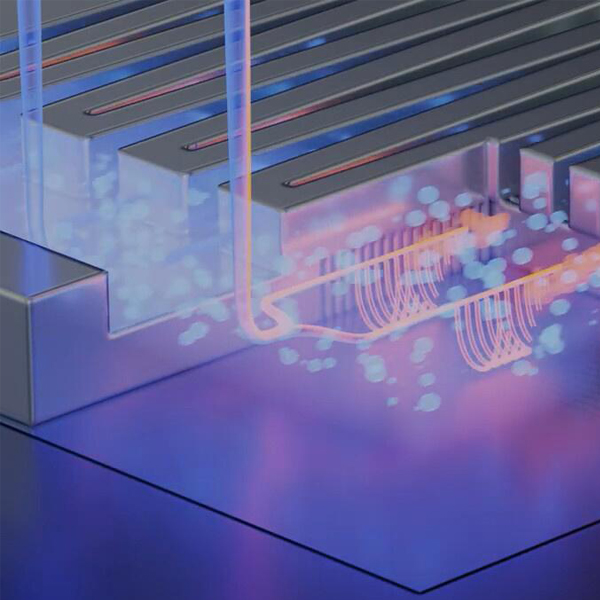

This exceptional performance is attributed to the perfect combination of innovative materials and microchannel networks (with channel widths of just a few micrometers), enabling miniaturized liquid cooling. In particular, on-chip cooling technology involves etching microchannels directly onto semiconductor substrates, allowing the heat-conducting fluid to be in close contact with the chip, thereby minimizing heat radiation losses and achieving further size reduction of the device.

Research shows that the cooling performance of on-chip liquid heat sinks far exceeds traditional microchannels, by up to 50 times, and such designs often use water as the fluid. By adopting on-chip microchannels with chemical coolants, device manufacturers can expect even more significant improvements.

The emergence of microchannel liquid cooling technology also opens up possibilities for other optimization strategies, with component stacking being particularly noteworthy. Since bulky cooling infrastructure is no longer required, components can be stacked rather than placed adjacently, thereby avoiding excessive heat accumulation.

This packaging technology not only helps reduce signal delays and improve performance but also enables more compact circuit designs, assisting manufacturers in overcoming traditional challenges associated with dark silicon.

Of course, the development of microchannel liquid cooling technology still faces some challenges. Manufacturing costs are high and the process is complex, with risks and difficulties involved in etching microchannels onto sensitive components. Additionally, scaled production may require upgrading to newer micromachining equipment, thereby affecting the cost-effectiveness of new devices.

However, as the technology continues to mature, its costs are expected to gradually decrease. Meanwhile, device manufacturers can address related issues independently without relying on semiconductor factories that provide such cooling systems. Research indicates that etching channels on readily available consumer-grade chips can reduce thermal resistance by 44.4%.

As microchannels enable more functionality at lower temperatures, the electronics industry may face new challenges. Once thermal constraints no longer limit chip performance, power delivery issues may arise. Therefore, manufacturers need to be cautious about designing overly powerful chips that could make power supply costs too high.

Although this conflict may still be distant, electronic manufacturers utilizing microchannel liquid cooling technology should pay attention to these long-term impacts and actively seek potential solutions.

As electronic products become increasingly miniaturized, cooling technology also needs continuous innovation. In this context, etching microchannels directly onto substrates has emerged as a highly promising solution, especially when combined with component stacking technology. Despite the challenges, electronic manufacturers can still reap many benefits by exploring and implementing these methods.