In the design and manufacturing process of electronic products, heat dissipation has always been a core issue that designers and engineers need to focus on. With the continuous development of processors, graphics cards and other high-performance chips, how to effectively dissipate heat to prevent equipment overheating has become an important determinant of performance and life. In this process, Thermal Interface Material (TIM) plays a crucial role.

Thermal Interface Material (TIM) is a material used between two heat sources, which is mainly used to enhance the heat transfer efficiency and reduce the thermal resistance between the heat source and the heat sink. Typically, in microelectronic devices, the contact surface between the chip and the heat sink usually has irregularities or tiny voids, which can significantly increase the thermal resistance and reduce the heat transfer efficiency. Therefore, thermal interface materials are used in electronic devices between processors, graphics cards and heat sinks, etc., to fill the tiny gaps between the two and ensure that heat can be efficiently conducted from the electronic components to the heat sink device.

The Importance of Thermal Interface Materials

In modern high-performance electronic devices, thermal management is a key factor in maintaining system stability and extending service life. If heat dissipation is poor, excessive temperatures can lead to:

-Performance degradation: Overheating can lead to downclocking or protective shutdown of core components such as the processor, seriously affecting the performance of the device.

-Hardware damage: Long-term excessive temperature will accelerate the aging of hardware, and even cause irreparable damage.

-Decrease system stability: An environment with large temperature fluctuations will lead to system instability, even leading to blue screen of death, lagging and other phenomena.

Thermal Interface Material (TIM) can effectively reduce these risks, enhance the cooling efficiency of the device, and ensure that the device can still maintain good performance under high load for a long time. By choosing the right TIM, you can not only improve the thermal performance, but also reduce energy consumption, minimize noise, and extend the service life of your hardware.

Types and Benefits of Thermal Interface Materials

There are many types of thermal interface materials, the following types are common, each with different characteristics and advantages.

1. Thermal Paste (Thermal Grease)

Thermal Paste is one of the most common thermal interface materials and is widely used between processors and heat sinks. It consists of components such as metal oxides and silicone-based oils, which are able to fill in the tiny voids on the contact surfaces, thus increasing the efficiency of heat transfer.

Advantages: Thermal paste has high thermal conductivity and is suitable for most computer hardware. Easy to use and cost-effective.

Disadvantages: After a long time of use, the thermal paste may dry up, resulting in a decrease in thermal conductivity.

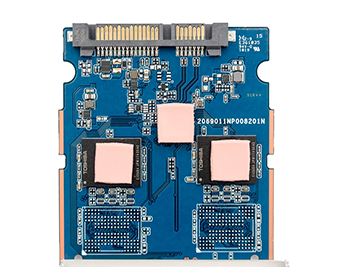

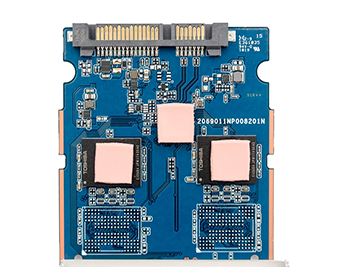

2. Thermal Pad

Thermal pad is a solid material of uniform thickness, usually composed of silicon, polymers and fillers. It is commonly used between heat sinks and electronic components, especially where large areas need to be covered.

Advantages: Easy to install, no need to apply; suitable for automated production lines. Compared to thermal paste, thermal pads are more stable and less likely to dry out.

Disadvantages: Thermal conductivity is usually inferior to thermal paste.

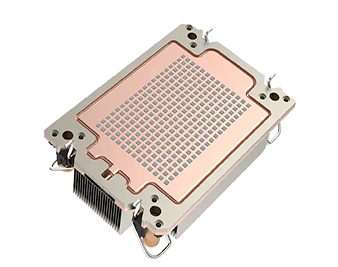

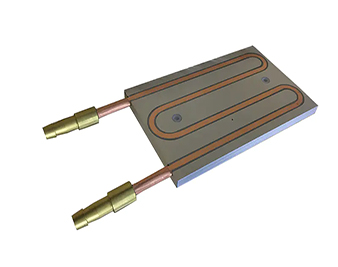

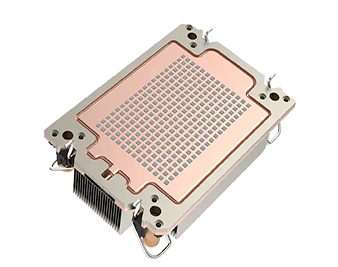

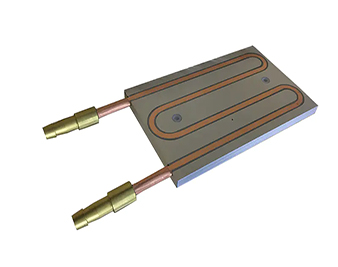

3. Heat Pipes

Heat Pipes are a common heat sink component. Although it is not a thermal interface material in the traditional sense, heat pipes are used with epoxy resins in some efficient thermal solutions to enhance heat transfer efficiency.

Advantages: High thermal conductivity, suitable for high power dissipation needs.

Disadvantages: Higher price, complicated installation.

4. Thermal Adhesive

Thermal Adhesive is a solid state glue, commonly used in those occasions that do not require frequent disassembly. Its main advantage is that it can provide strong adhesive force to fix the radiator.

Advantages: Strong adhesion to hold the heat sink in place.

Disadvantage: Once applied, it is difficult to remove, and the scope of application is limited.

5. Graphite Sheets

Graphite Sheets are a flexible material with good thermal conductivity, and are commonly used in consumer electronics such as cell phones and tablets.

Advantages: Good thermal conductivity, flexible, and suitable for large-area contact.

Disadvantages: Slightly less thermally conductive compared to thermal paste.

How to choose a thermal interface material?

There are several factors to consider when choosing the right thermal interface material, including the device's heat dissipation needs, the environment in which it will be used, the material's performance and cost. Below are some key recommendations for selecting a thermal interface material:

1. Thermal Conductivity

Different types of thermal interface materials vary greatly in thermal conductivity. Generally, thermal paste has superior thermal conductivity and is suitable for high performance electronic devices. For general consumer electronics, thermal pads or graphite sheets may be sufficient.

2. Application Scenarios

When choosing a thermal interface material, it is very important to consider the environment in which the device will be used. If the device needs to run in a high-temperature environment for a long period of time, it is recommended to choose a material with excellent thermal conductivity and strong stability, such as high-end thermal paste or thermal conduit. For devices that are not often disassembled, thermally conductive adhesive can provide better fixation.

3. Cost-effectiveness

Different types of thermal interface materials vary greatly in price. For products with limited budget, thermal pads or thermal paste is a cost-effective option, while for high-end hardware, investing in some high-performance thermal materials, such as high thermal conductivity thermal paste or graphite flakes, can ensure the stable operation of the device for a long time.

4. Ease of Installation

Thermally conductive paste needs to be applied carefully, and is prone to uneven coverage due to improper handling. Thermal pads, on the other hand, are much easier to install and are suitable for mass production and automated production lines. Choosing the material that suits the needs of your production line can improve production efficiency.

5. Environment and temperature

The temperature resistance of different materials also varies greatly, especially in some industrial-grade applications, the selection of materials needs to consider the stability of the material in a high-temperature environment. Typically, high-quality thermal paste or thermal pads can withstand higher temperatures, while thermal adhesives may fail at high temperatures.

Thermal interface materials play a critical role in the cooling system of electronic devices. the right choice of materials can significantly improve the thermal performance of the device, extend its service life and improve system stability. lori's thermal solutions will help you select the right thermal interface material based on a number of factors, including application scenarios, thermal conductivity requirements, cost budget and other factors, to effectively improve the overall performance of the device. In the future, as electronic technology continues to advance, thermal interface material technology will also continue to evolve, and Lori will provide more efficient and intelligent thermal solutions.