With the rapid development of the new energy vehicle market, range and safety have become the two main concerns for consumers. To meet these demands, automotive manufacturers have raised their requirements for thermal management in new energy passenger vehicles. In particular, significant research is being conducted by various manufacturers on cooling structures like brazed water cooling plates.

Battery cooling technology is one of the key technologies for new energy vehicles, mainly including air cooling, liquid cooling, and direct cooling. Air cooling technology has been widely applied in electric buses, while liquid cooling is more common in passenger vehicles. Although direct cooling technology has the highest requirements, it is considered the future direction for electric vehicles.

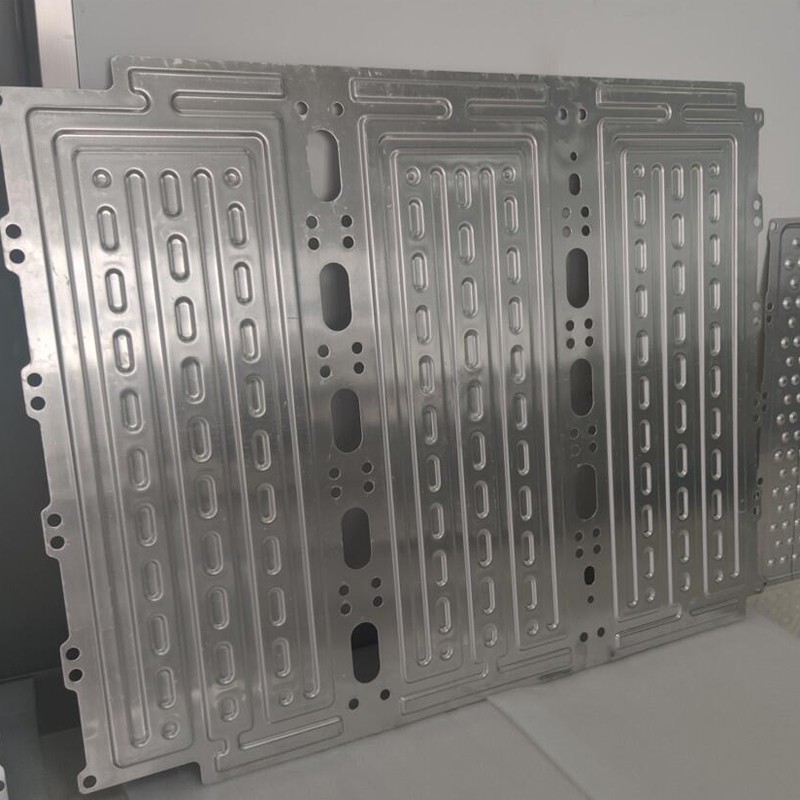

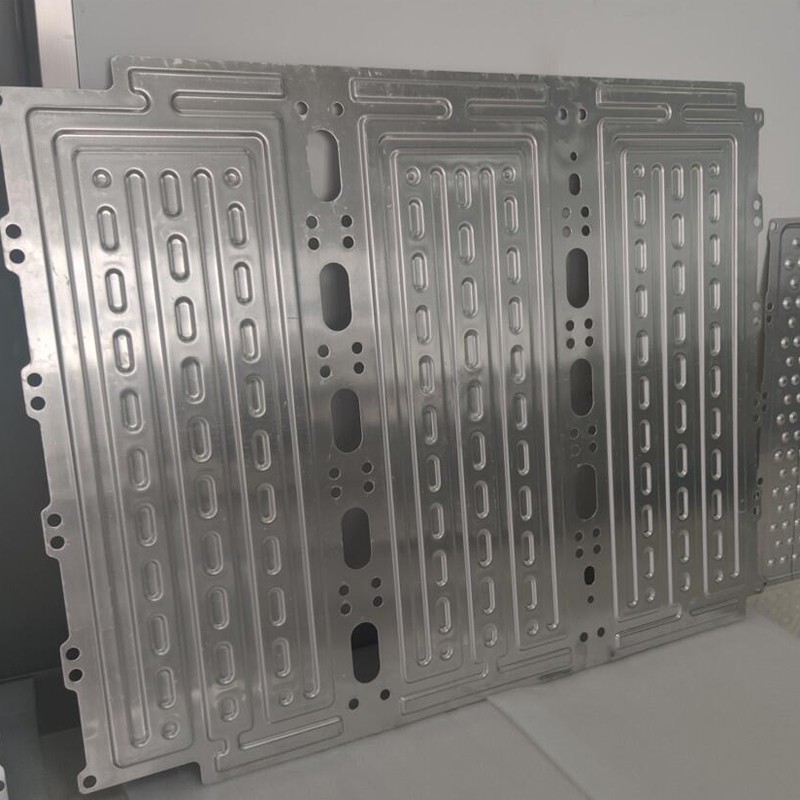

The battery cooling system in new energy vehicles consists of several important components, including the battery, battery cooler, and water cooling plates. The brazed water cooling structures mainly consist of water cooling plates and direct cooling plates, which are typically made from two upper and lower O-state aluminum plates that are brazed together. This design allows the coolant to circulate through the stamped flow channel structure, continuously cooling the battery.

When selecting materials for water cooling plates, the primary considerations are material strength and corrosion resistance. By combining high-strength composite materials with water cooling plate structures, it is possible to achieve thinning and cost reduction. Therefore, the development of new materials is crucial for the advancement of water cooling plates.

Currently, suppliers of aluminum brazed water cooling plates are concentrated among a few companies, resulting in a high industry concentration. In the niche market for wide EV water cooling plates, there are very few companies capable of supplying these products. This situation necessitates that downstream battery manufacturers establish deep collaborative relationships with aluminum brazed water cooling plate companies during the product development phase, leading to a high degree of customization. The entire process—from component design, production line certification, to product sampling, ramping up production capacity, and improving yield—can take up to three years, creating significant qualification barriers for new entrants.

Lori has been focused on the water cooling plate radiator field for nearly a decade. We have extensive experience in customizing water cooling plates for electric vehicles. If you need assistance, please feel free to contact us!