As a traditional production process for high-power heat sinks, the bonded fin heat sink commonly employs a tight-fit riveting method. However, this approach can lead to potential heat dissipation risks such as fit clearance and loose fins. In recent years, Lorithermal has introduced various new medium connection technologies through technological innovation, including the use of high-thermal-conductivity epoxy resin bonding, brazing, and tin soldering. These methods significantly enhance the reliability and stability of heat dissipation, mitigating the existing risks.

Product Features of Bonded Fin Heat Sink:

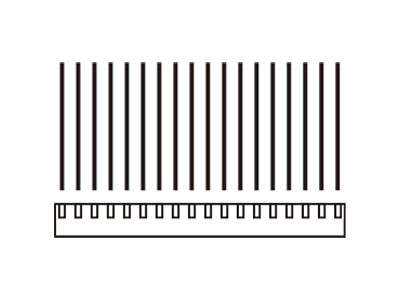

Dense fins with small inter-fin spacing, offering flexibility in height and width dimensions to suit different usage spaces. Its small size and light weight make it an ideal choice for heat sinks for high-power devices.

Production Process of Bonded Fin Heat Sink:

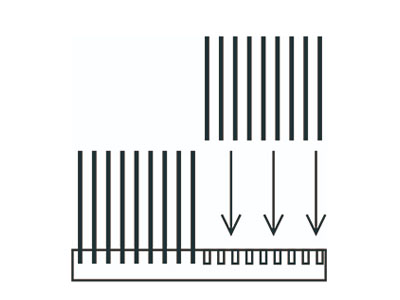

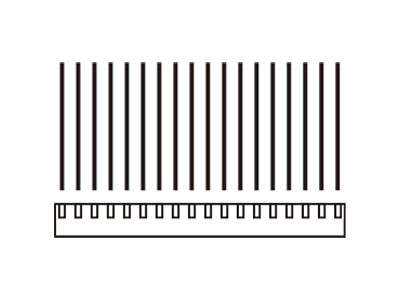

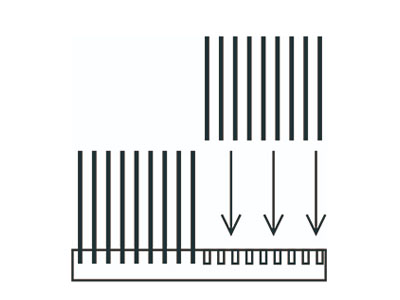

1.Design and manufacture the aluminum/copper baseplate and fins for heat dissipation, and groove the baseplate.

2.Use epoxy resin bonding or other methods to insert the fins into the baseplate and assemble them into a single unit.

3.After fixing the baseplate and fins, perform surface finishing to shape the bonded fin heat sink.

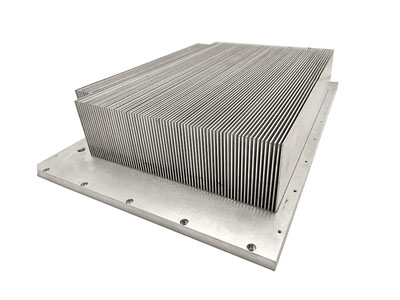

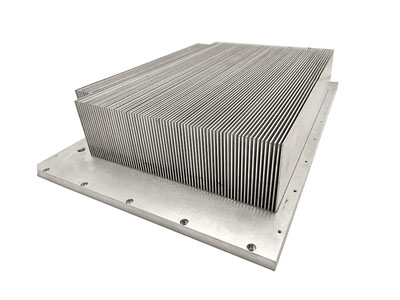

Bonded Fin Heat Sink Image Example: