Lori Custom Aluminum Cold Plate Liquid Cooling Loops

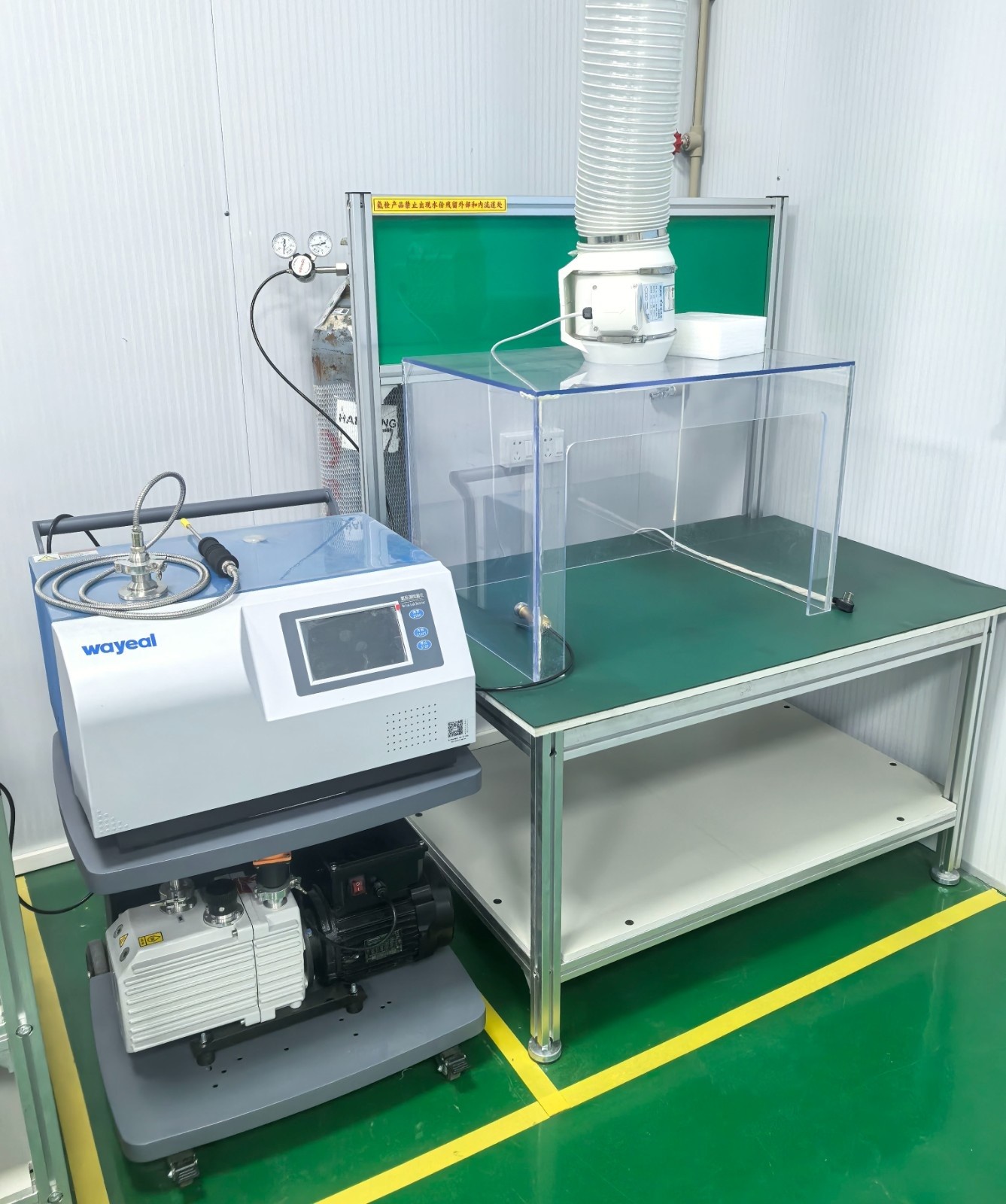

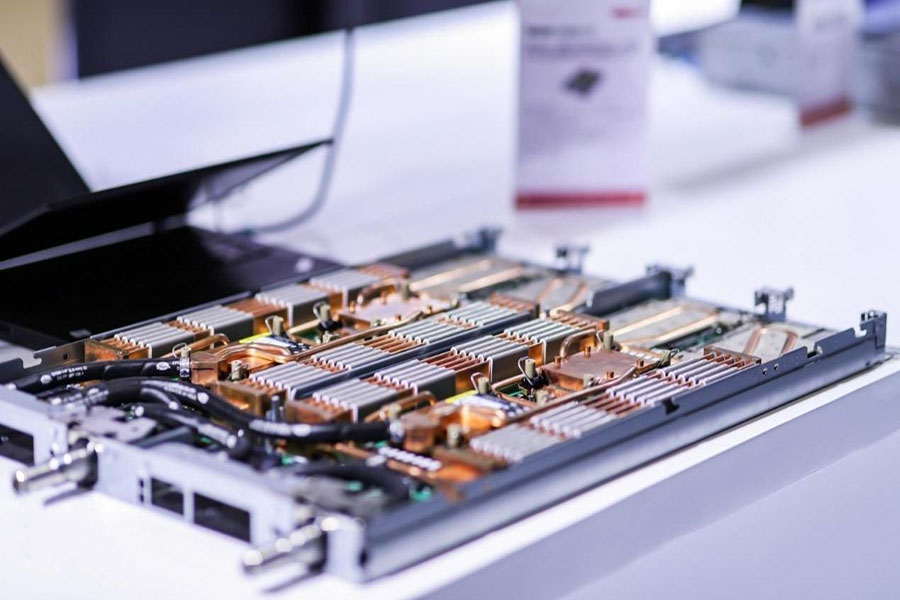

This open loop liquid cooling system is composed of two custom aluminum cold plates, PTFE pipes and joint, and is mainly used in servers or data centers. It can meet the requirements of AMD SP3 socket and can also be customized to accommodate other standard and non-standard platforms. The entire liquid cooling loop system adopts an all-aluminum brazing process to ensure no leakage in the liquid cooling system. Aluminum cold plates have an ultra-thin structure and can absorb the heat of chips in some narrow spaces with limited height. This liquid cooing loop components are rarely assembled manually, which greatly reduces the evapotranspiration rate. Lori liquid cooling loops undergo strict thermal testing and leakage detection, ensuring both heat dissipation efficiency and product quality and usage safety.