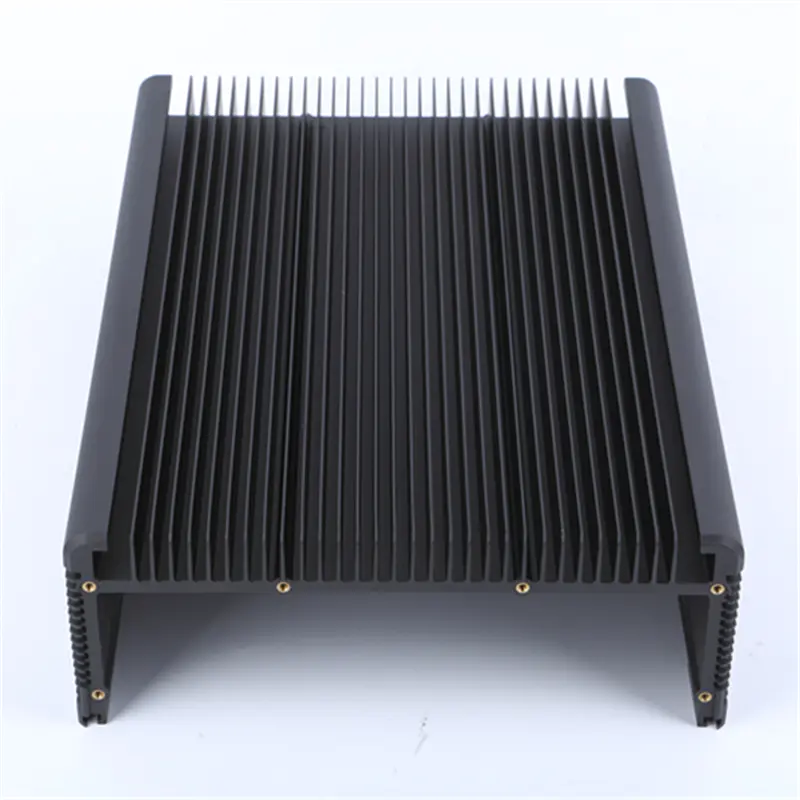

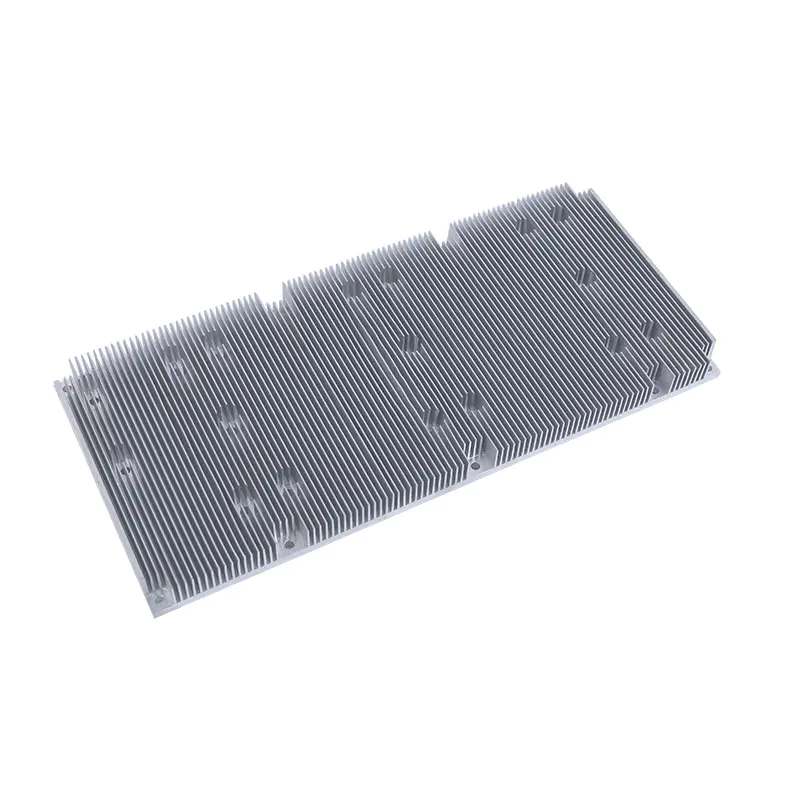

As an important component in the cooling of electronic products and electronic equipment, the main function of the heat sink is to dissipate the heat generated in the operation of electronic products and electronic equipment to ensure that the equipment can operate normally. With the rapid development of electronic equipment, the heat dissipation needs of electronic equipment are also getting higher and higher.In order to meet the heat dissipation needs of our customers, Lori customizes heat sinks with stronger heat dissipation capabilities in terms of increasing the surface area of heat dissipation, increasing the convection heat transfer rate, increasing the thermal conductivity, and increasing the radiant heat transfer rate, etc., so as to cool the electronic products and equipment for our customers, increase their service life, and reduce costs and increase efficiency.

Radiant heat transfer mainly affects indoor natural heat dissipation products and outdoor products exposed to the sun, in addition to expanding the area of the heat sink, but also need to choose the appropriate surface treatment. Commonly used surface treatment methods include painting, sandblasting to improve roughness, anodizing, plating and other measures. The most common surface treatment in cooling electronic products is surface anodizing. Anodizing treatment not only improves the radiating performance of the heat sink, but also enhances its antioxidant performance, thus increasing the heat dissipation capacity.

What is anodizing?

Anodizing is a method of treating the surface of an object through an electrochemical reaction. In anodizing, the treated object will act as an anode, and through the action of electrolytic solution, a hard film will be formed on its surface, which will have the effect of anticorrosion, rust prevention and beautification.The process of anodizing generally includes: cleaning, anodic treatment, sealing hole treatment, coloring and sealing. Among them, the oxide layer of standard anodizing process is between 1.8-25 microns, and the coating of hard anodizing is more than 25 microns.

The effect of anodizing on the heat dissipation effect of the heat sinks

Enhanced heat sink performance: Anodizing treatment can improve the radiant performance of the heat sink, reflecting more heat and reducing the absorption and re-radiation of heat, thus improving the heat dissipation efficiency.

Enhanced antioxidant performance: the oxide film formed by anodizing has good anticorrosion performance, which can protect the surface of the heat sink from corrosion and prolong its service life.

Increased surface hardness: The surface hardness of the treated heat sink is increased, which can resist external abrasion and scratches, and maintain the beauty and function of the heat sink.

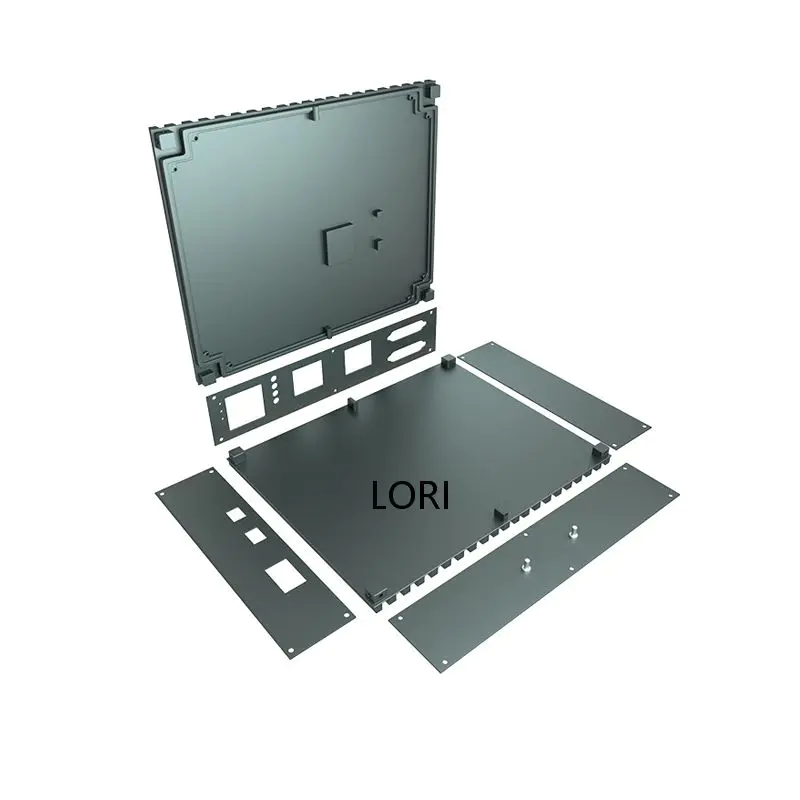

Anodizing is an effective surface treatment for heat sinks, which can significantly improve the heat dissipation performance and service life of heat sinks.Lori can design anodized heat sinks according to customers' needs, which can be applied to desktop computers, AR/VR, projectors, smart homes and other consumer electronic devices. We use systematic thermal design theory knowledge to solve customers' needs and provide more efficient heat dissipation solutions.