| Place of Origin: | Shenzhen, China (Mainland) | OEM: | Yes |

| Process: | Soldering | Temper: | T3-T8 |

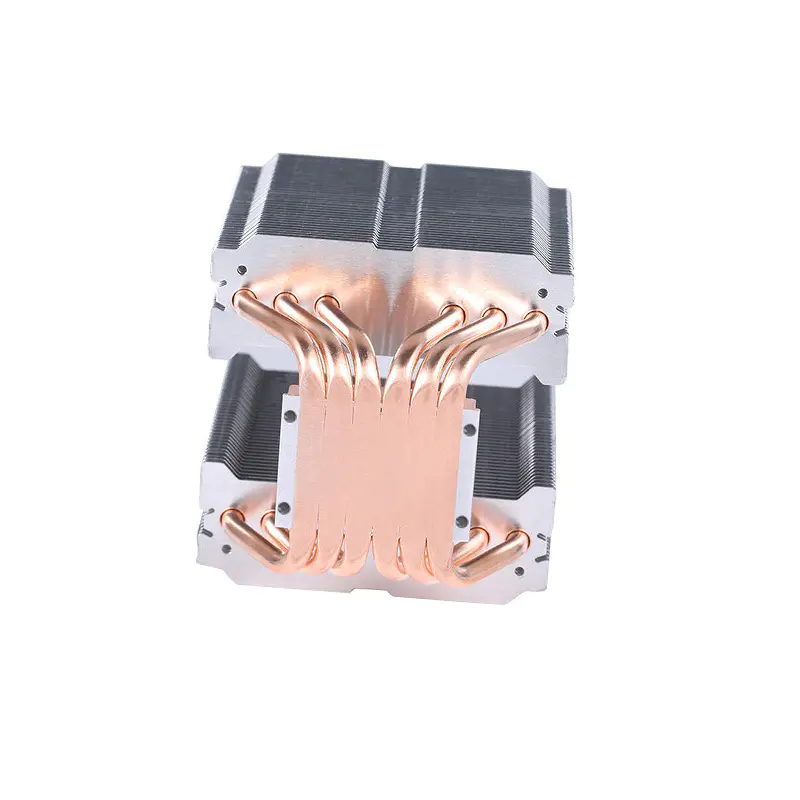

| Material: | Copper heatpipe+ Aluminum fin+ Aluminum base | Shape: | Square |

| Packing: | Paper carton with wooden pallet | Brand Name:

| LORI

|

| Application: | laptop cpu, led

| Certificate: | ISO 9001:2015,ISO 14001:2015 |

| Model Number: | LR0171 | Tolerance:

| 0.01 mm |

| Finish: | Passivation | Quality control: | 100% thermal test |

| Extra process: | Stamping+CNC Machining | Size: | Custom size |

This copper heatpipe aluminum heatsink has the following features:

Descriptions:

High power copper heatpipe heat sink

Copper heatpipe heat sink for Cpu

Copper heatpipe aluminum heatsink for Cmputer

Specifications:

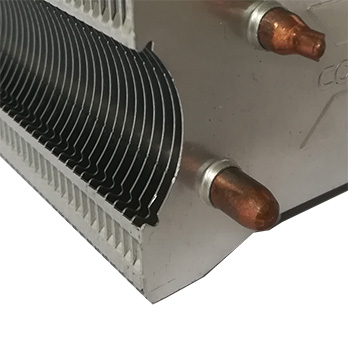

Aluminum fin thickness: 0.5mm

Copper heatpipe: 8mm in diameter

Copper heatpipe quantity: 2pcs

Material: copper heatpipe + aluminum fins + aluminum base

This copper heatpipe aluminum heatsink has the following details:

Precision copper pipe heatsink

Aluminum fin heatsink with copper pipe

Depend on customer's requirements

Copper heatpipe aluminum heatsink has following processing technique:

Aluminum fins: Progressive die stamping process

Aluminum base: Extrusion + CNC machining process

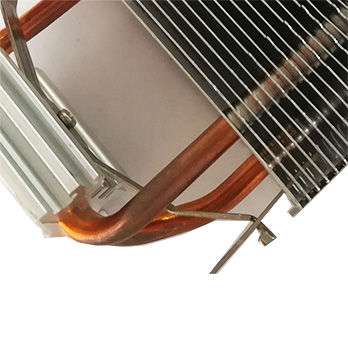

Copper pipe: forming: automatic pipe bending+ burn into tip ends

Aluminum base anodizing, copper heatpipe passivate (insulation, oxidation and corrosion resistance)

Assembly: Automatic fins wearing/assembly, then fixed by overflow soldering and screw/rivet combination

Quality: 100% Quality check and packing

Applied to Cpu, Computer, Communication, UPS, inverter, controller, wind power converter, SVG telecommunication.

◪ In order to ensure the best service to the customer , we have formulated this after-sales service system, the company solemnly to the users of after-sales service work to do the following commitment:

◪ 1.Provide online technical support for customers, and provide consulting services on related issues

◪ 2.From the date of spontaneous delivery, if there is any quality problem or quality objection to our company's customized products, please contact with us in time. After checking and coordinating, we can return and replace the products in time.