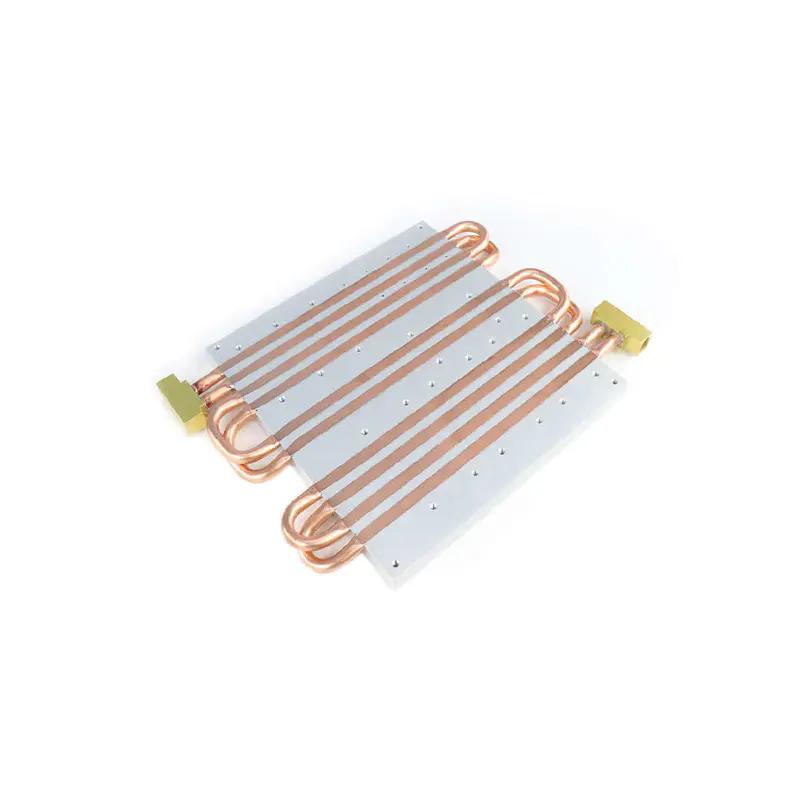

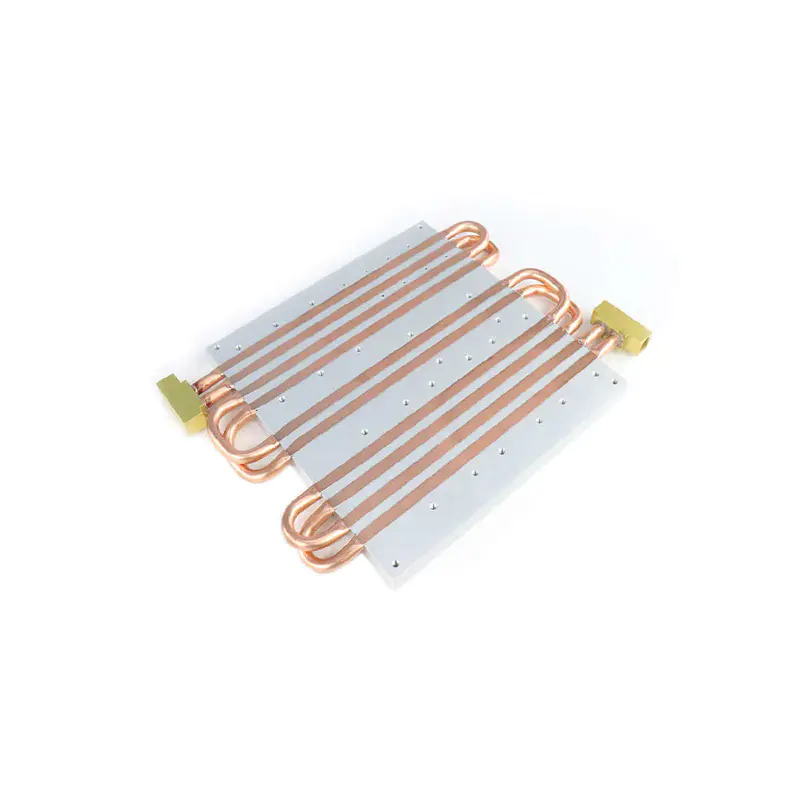

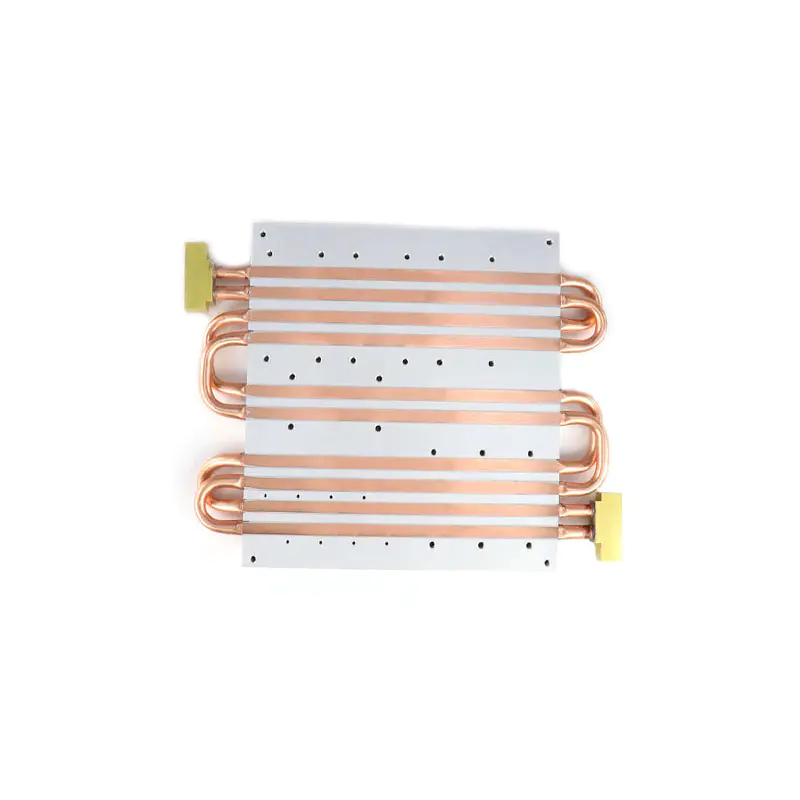

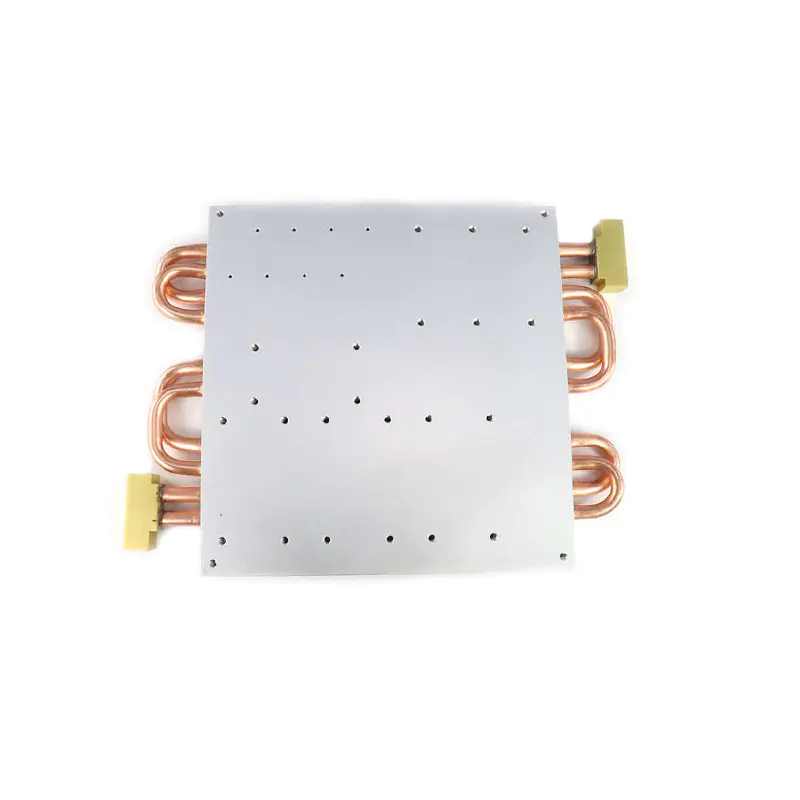

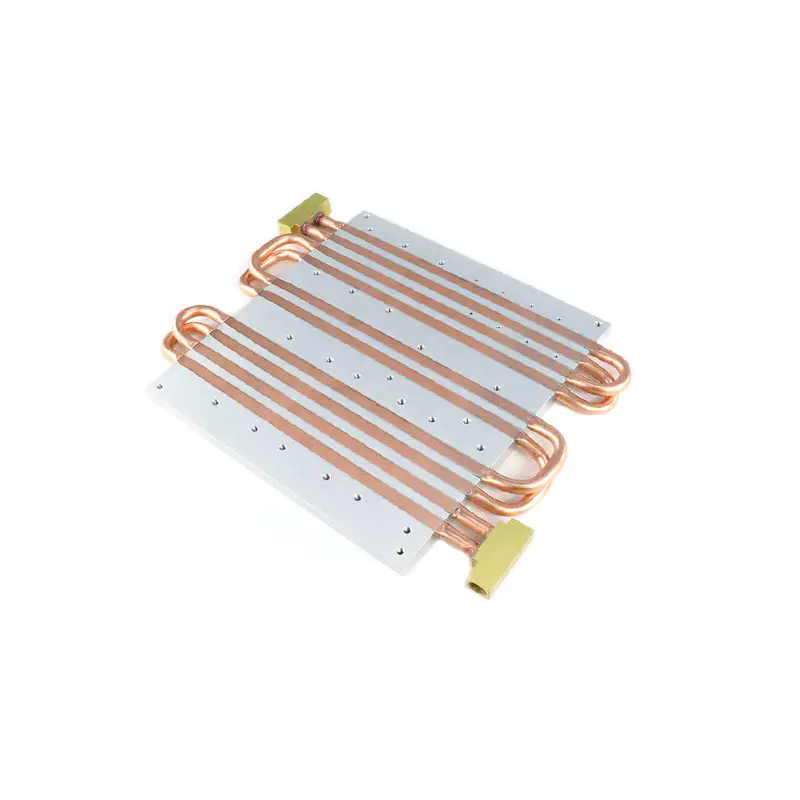

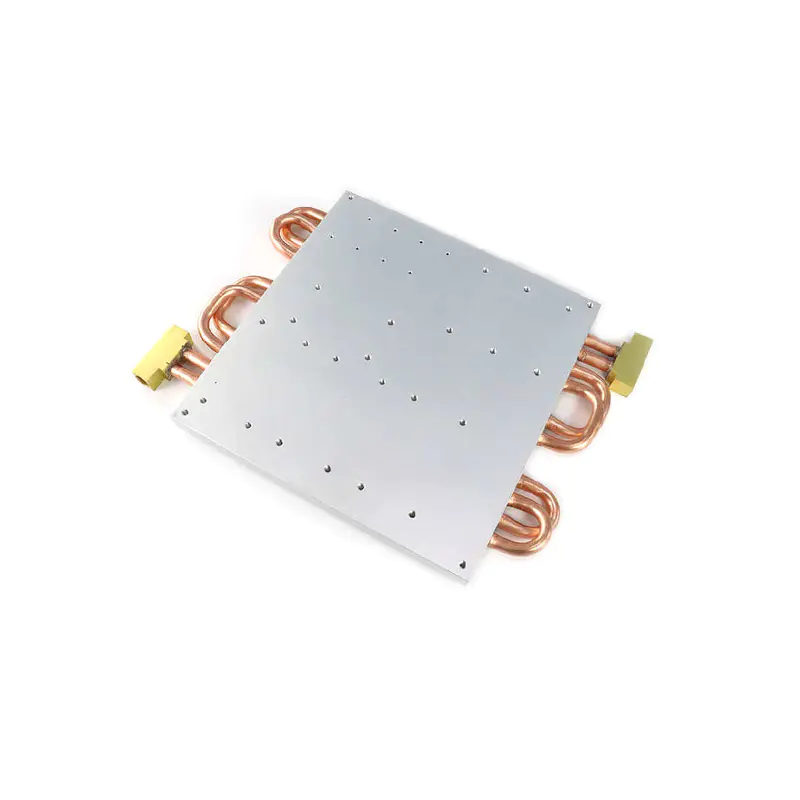

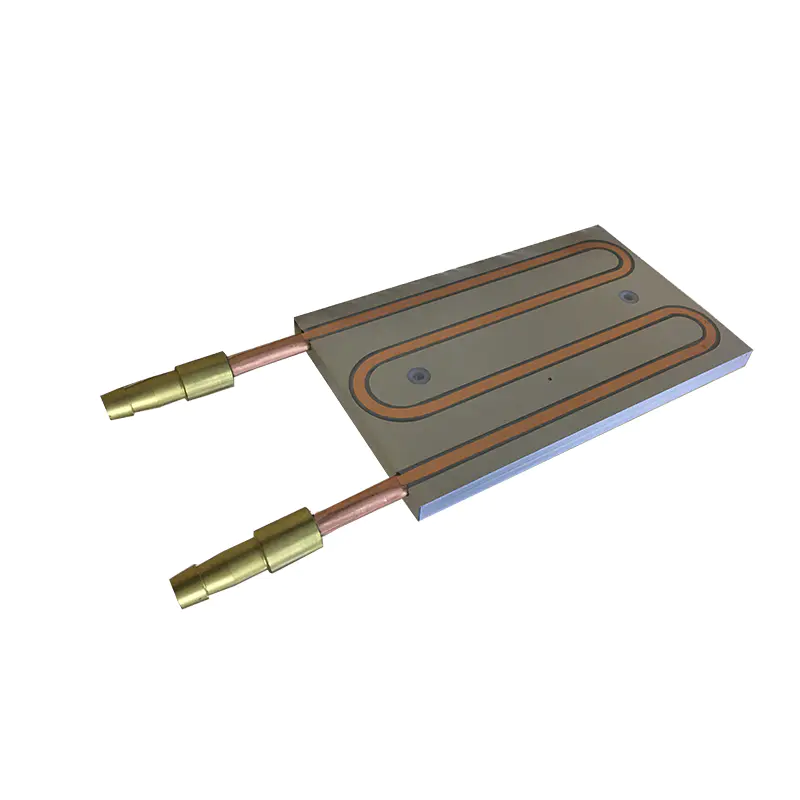

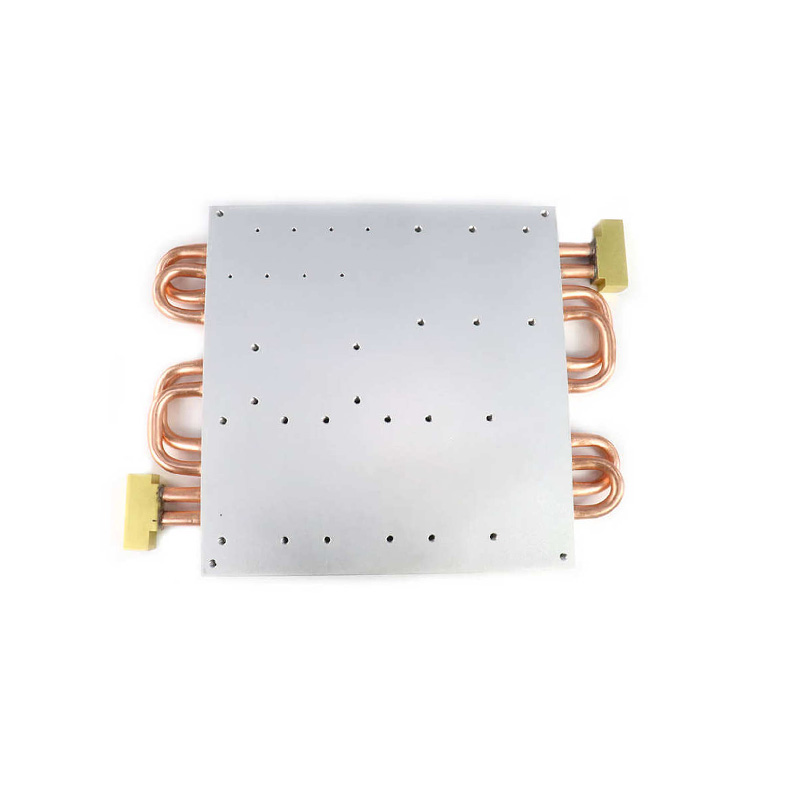

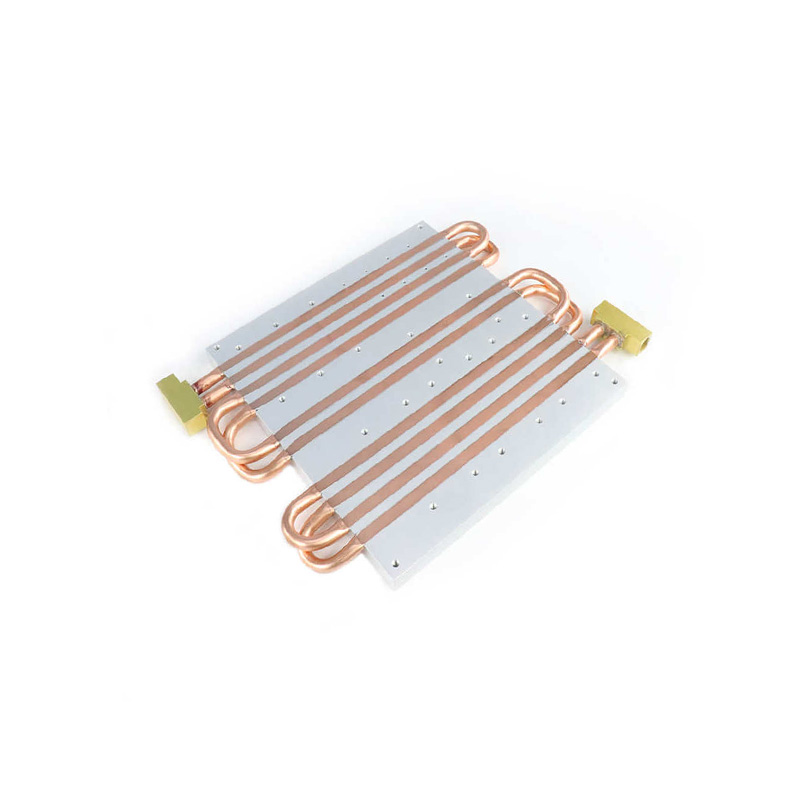

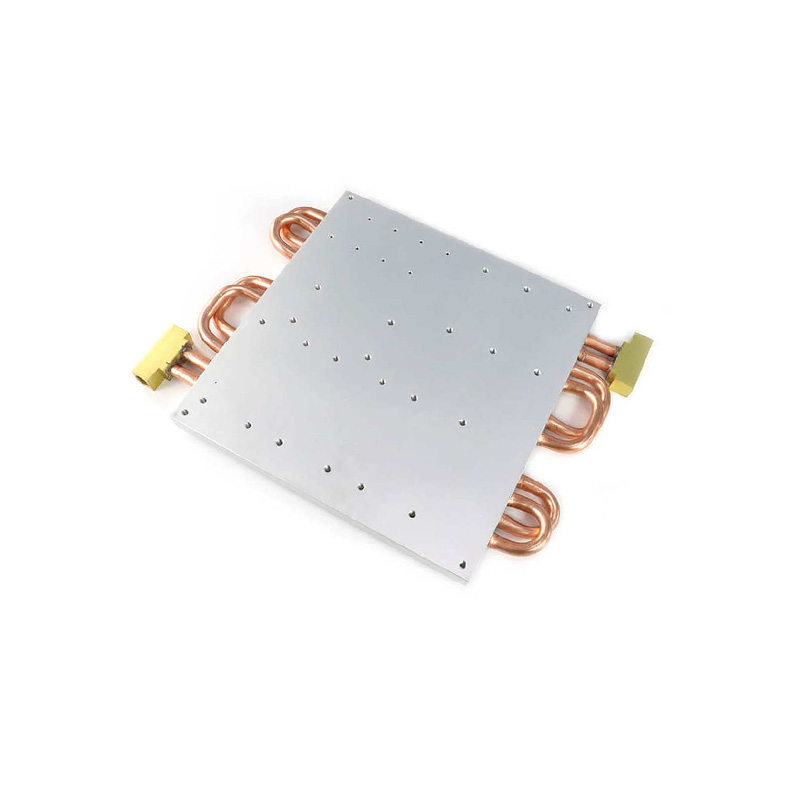

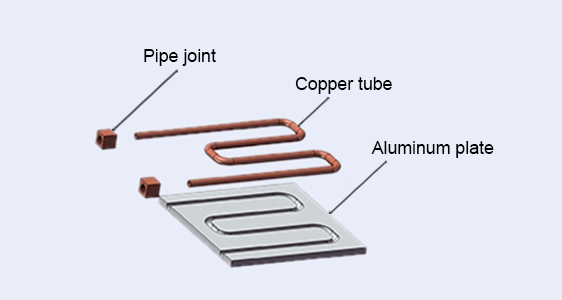

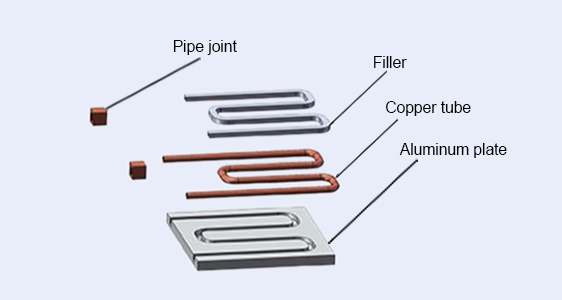

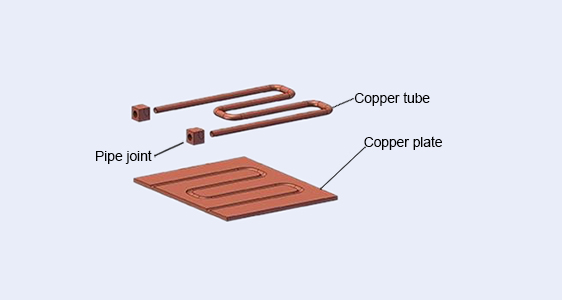

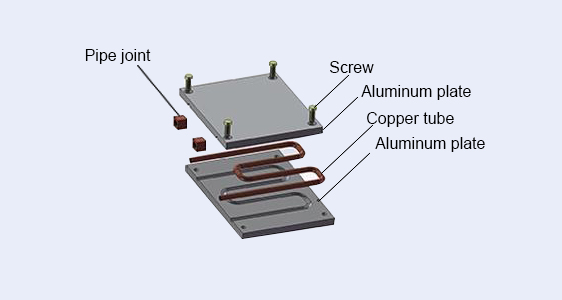

Copper Tube Aluminum Cold Plate Liquid Cooling Solution System

In power electronic control, transformation, driving, signal transmission, and other fields as well as new energy, new energy vehicle power battery cooling, UPS and cooling energy storage system, large server heat dissipation, large photovoltaic inverter heat dissipation, SVG/SVC heat dissipation, etc.), in the pursuit of high performance, low noise, low temperature operation, and is limited by space, heat dissipation problems become product development ideal big restrictions, cold plate liquid cooling heat dissipation technology become the preferred thermal management style. LORI thermal energy's thermal design and thermal management engineers have rich experience in cold plate cooling research and development and cold plates liquid cooling process production, and can provide a full range of liquid cooling solutions, free of charge to provide you with the advanced cold plate solution thermal design, structural design, cold plate cooling system assembly design and one-stop supporting services.