Skiving heat sink advantages

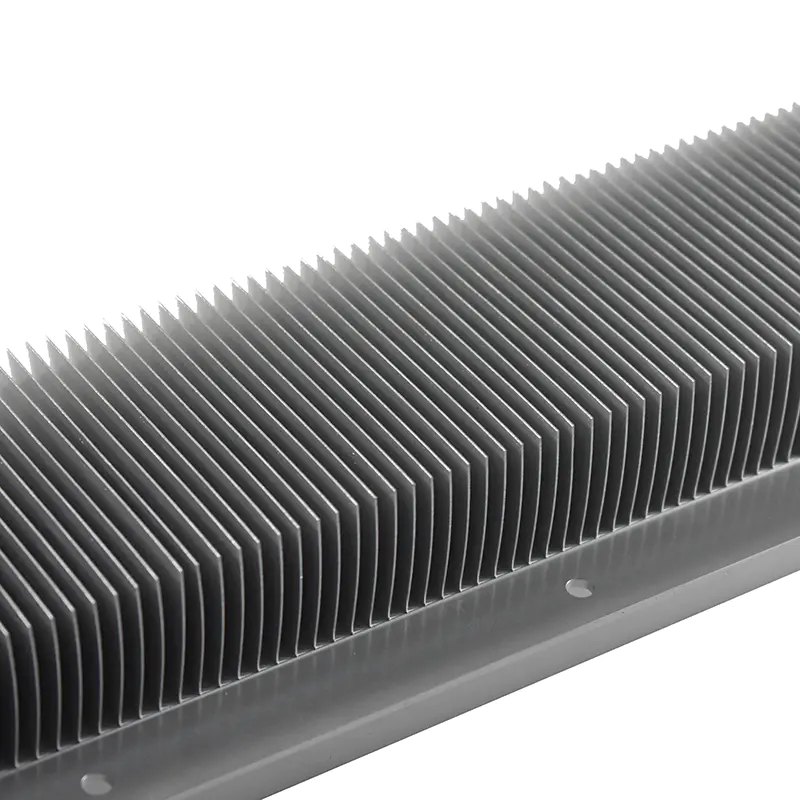

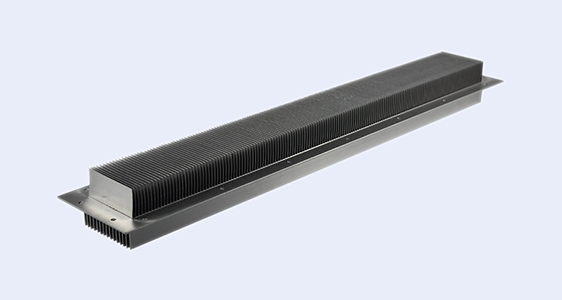

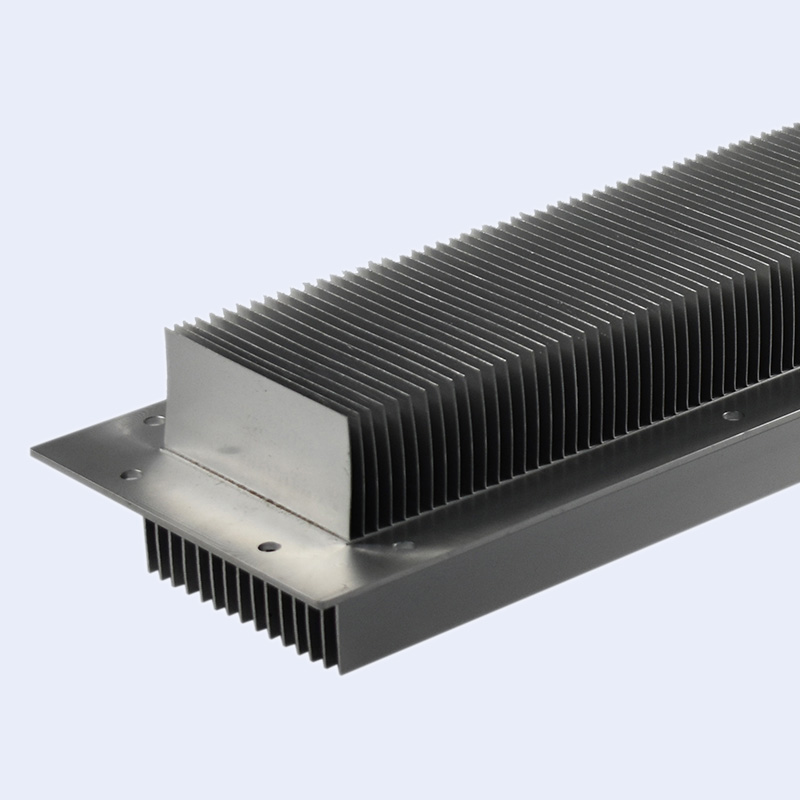

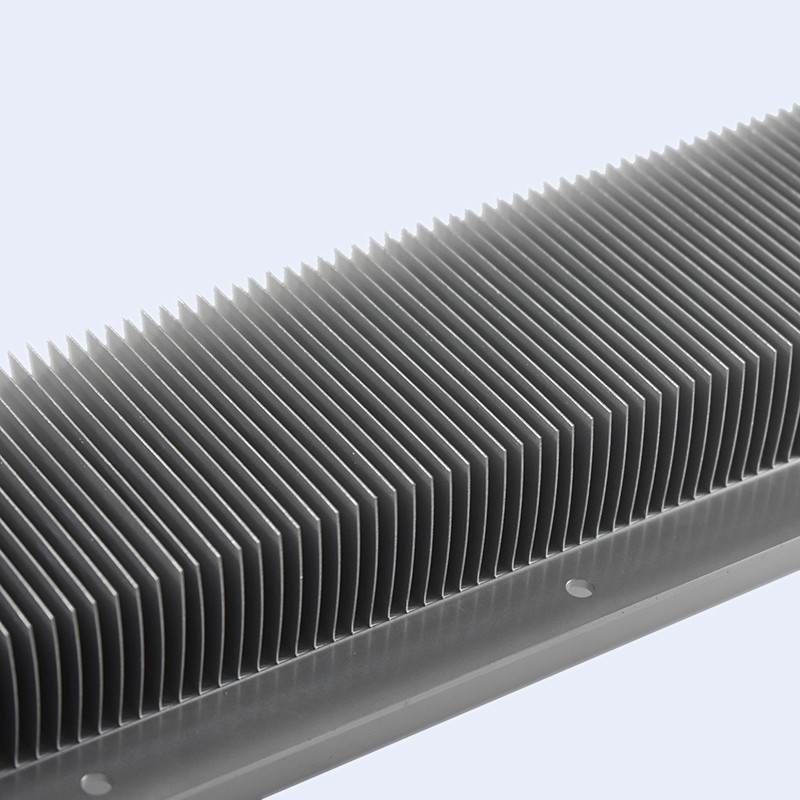

This skiving heat sink is very long with 1200 mm, and have fins in two sides , the one side fin is skived fin,

and the other side fin is extrusion fins. The skiving heat sink combined the advantage of extrusion and skived technology. and the material is alumibum. The process of the skiving heat sink as below.

Firstly, we make the extrusion mold for the base and extrusion fin heat sink.

Secondly, when the heat sink material get from extusion. we wil put the skiving heat sink material on the skived machine, cutting the base and form the skiving fin.

At last, we will machine the hole on the heat sink for assemble and finished with silver anodized.

This skiving fin heat sink can be an alternative to extruded heat sink when looking for high density which can’t be achieved by extrusion technology.