When selecting a supplier for heat sinks, clients need to meticulously evaluate multiple dimensions to ensure that the chosen partner perfectly aligns with project requirements and contributes to a significant leap in product performance and market competitiveness. Here’s a detailed and original guide to the critical factors in the selection process:

1. In-Depth Exploration of Processing Capabilities

Customization Art of Extrusion Processing: Leading suppliers excel in not only mold design and manufacturing but also in translating client visions into tangible products. They should offer bespoke extrusion solutions tailored to specific product characteristics. For instance, they might use advanced alloy materials to enhance thermal conductivity or integrate structural reinforcements within aluminum profiles to boost overall strength and durability. An exemplary supplier could offer a variety of extrusion profiles to meet diverse thermal management needs, from standard shapes to highly specialized configurations.

Micron-Level Precision in CNC Machining: CNC machining is a critical phase where precision matters. Suppliers should demonstrate expertise in handling intricate structures through advanced techniques. For example, using five-axis CNC machines can achieve complex geometric features and deep-hole drilling with high precision. This ensures that cooling channels remain unobstructed, minimizing fluid resistance and maximizing heat dissipation efficiency. Precision machining for components such as sealing surfaces should employ ultra-high-precision technology to achieve zero leakage, which is crucial for high-performance applications.

Fine Control in Drilling and Tapping: For multi-hole heat sinks, suppliers should be equipped with state-of-the-art drilling and tapping machinery. Advanced CNC programming should enable exact hole placement and efficient processing. For challenging materials or those with high hardness, selecting appropriate tooling and cutting parameters is essential. This minimizes stress concentration and ensures a smooth hole finish, which is vital for maintaining structural integrity and performance.

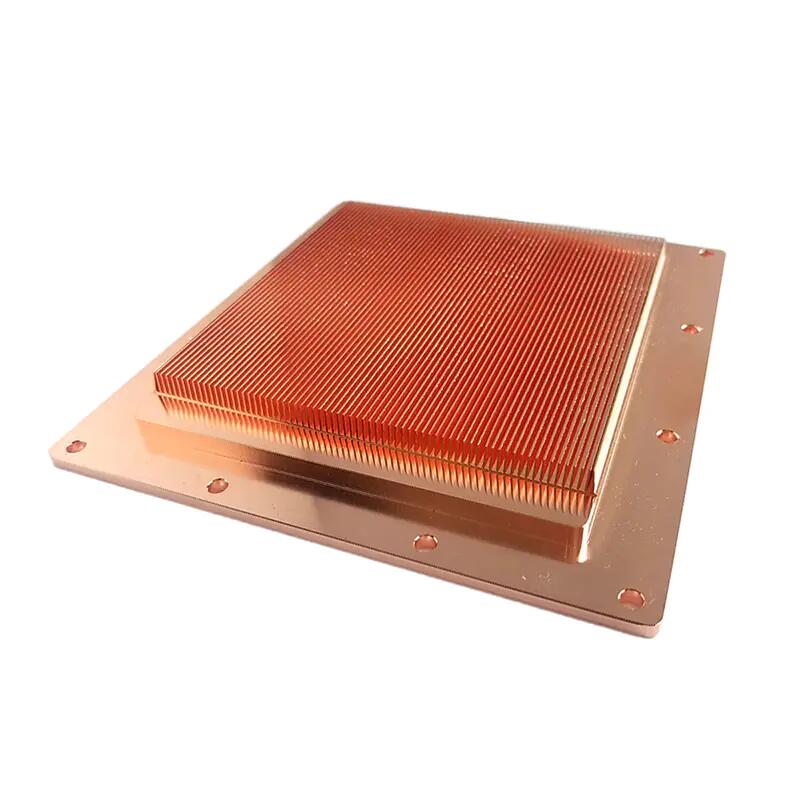

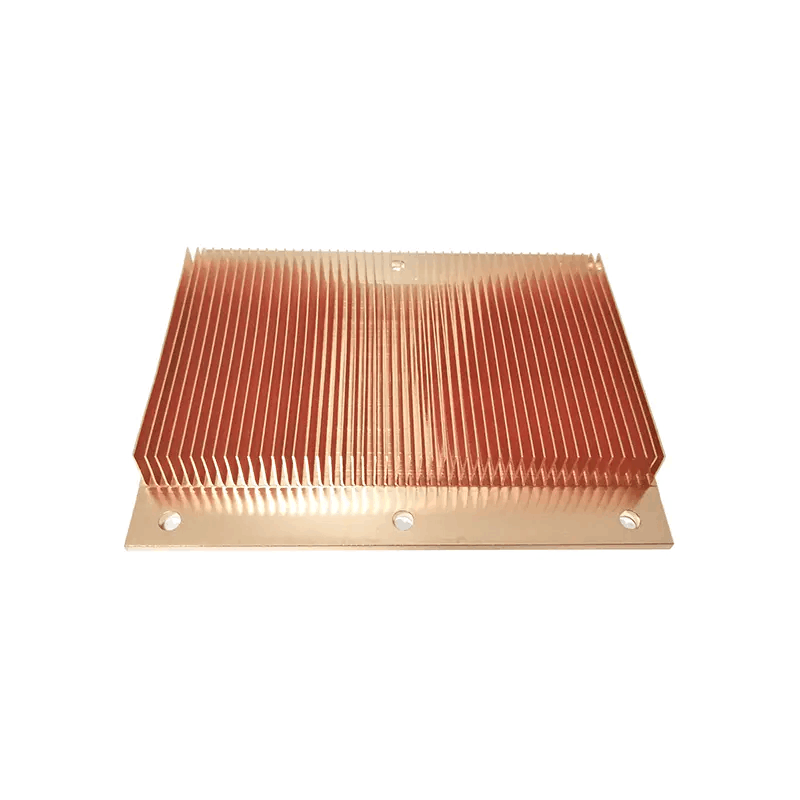

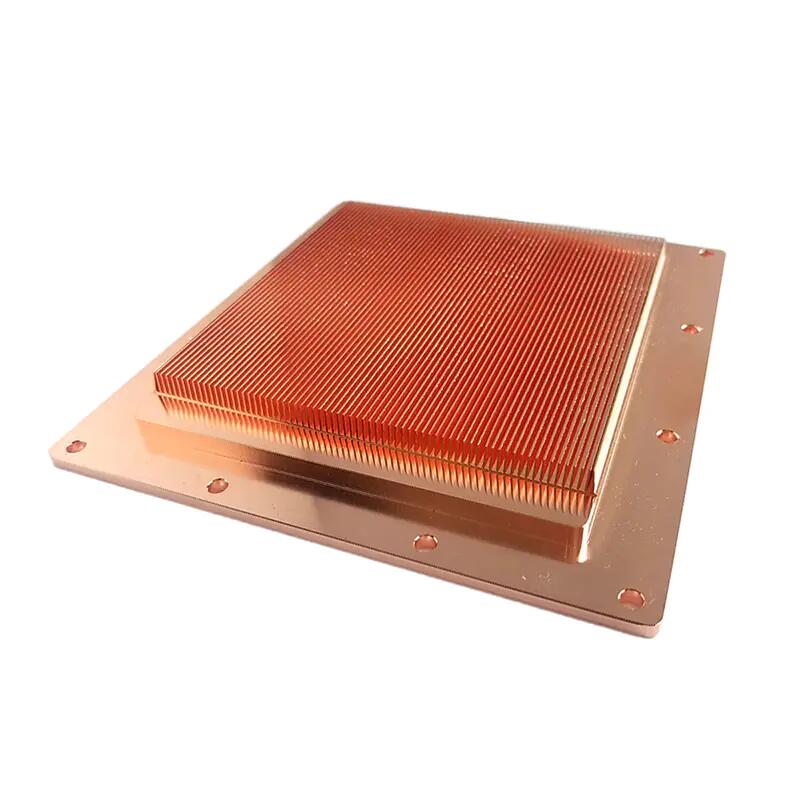

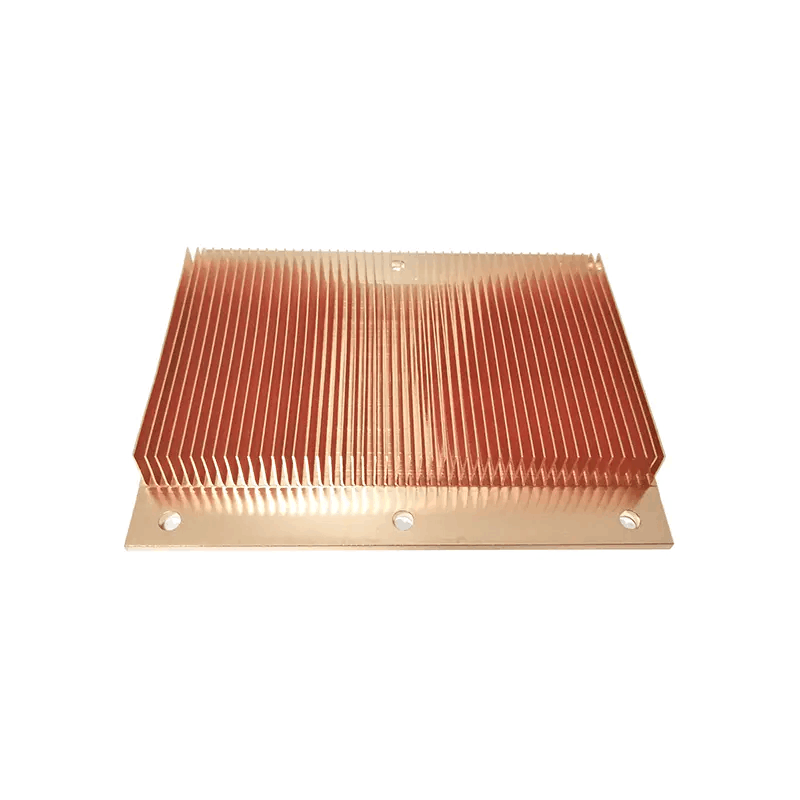

Artistry in Fin Machining: The fin machining process is pivotal in heat sink production. Suppliers should exhibit mastery in selecting cutting tools, planning cutting paths, and optimizing cutting parameters. For instance, using diamond-coated tools can enhance cutting efficiency and prolong tool life. Additionally, implementing intelligent control systems that monitor the machining process in real-time ensures that fin precision and consistency are maintained, which is critical for optimizing thermal performance.

Perfect Finish in Gear Cutting: Gear cutting machines must balance efficiency with precision. Suppliers should ensure that their gear cutting machines have automatic leveling features to eliminate sharp edges on fin tips and maintain consistent fin spacing. This not only enhances the heat sink's aesthetic appeal but also ensures its safety and functional integrity.

2. Dual Assurance of Production Capacity and Delivery Efficiency

Flexible Production Line Configuration: Suppliers should have the capability to rapidly adjust production plans and capacity in response to client demands. This flexibility is achieved through adaptable production line configurations and a focus on a multi-variety, small-batch production model. Such a model caters to diverse market needs and ensures that clients receive products tailored to their specifications.

Efficient Logistics System: A comprehensive logistics system is crucial for timely and safe product delivery. Suppliers should establish a reliable logistics network with options for flexible delivery schedules and expedited handling of urgent orders. This system should be capable of adapting to market fluctuations and client requirements, ensuring that products are delivered on time and in optimal condition.

3. Comprehensive Customer Service and Technical Support

Customized Service Solutions: Suppliers should offer tailored service solutions that address specific client needs and challenges. This includes providing dedicated support throughout the product lifecycle, from initial design and process optimization to post-sales service. A professional team should be available to provide guidance and support, ensuring that clients receive the assistance they need to achieve their goals.

Rapid Response Mechanism: Establishing a rapid response mechanism is essential for addressing client issues promptly. This includes setting up customer hotlines, online support platforms, and dedicated account managers who can provide timely and effective solutions. Ensuring seamless communication and collaboration with clients helps build trust and fosters long-term partnerships.

The right heat sink supplier ensures optimal product quality and production efficiency. So the importance of the right supplier is self-evident. Lori has focused on the field of heat dissipation for nearly ten years. We can not only meet the complex heat sink design needs, but also provide fast delivery and quality after-sales service to help you improve the heat dissipation efficiency and market competitiveness of your products.Choose Lori, Choose free from worry.