| Place of Origin: | Shenzhen, China (Mainland) | Temper: | T3-T8 |

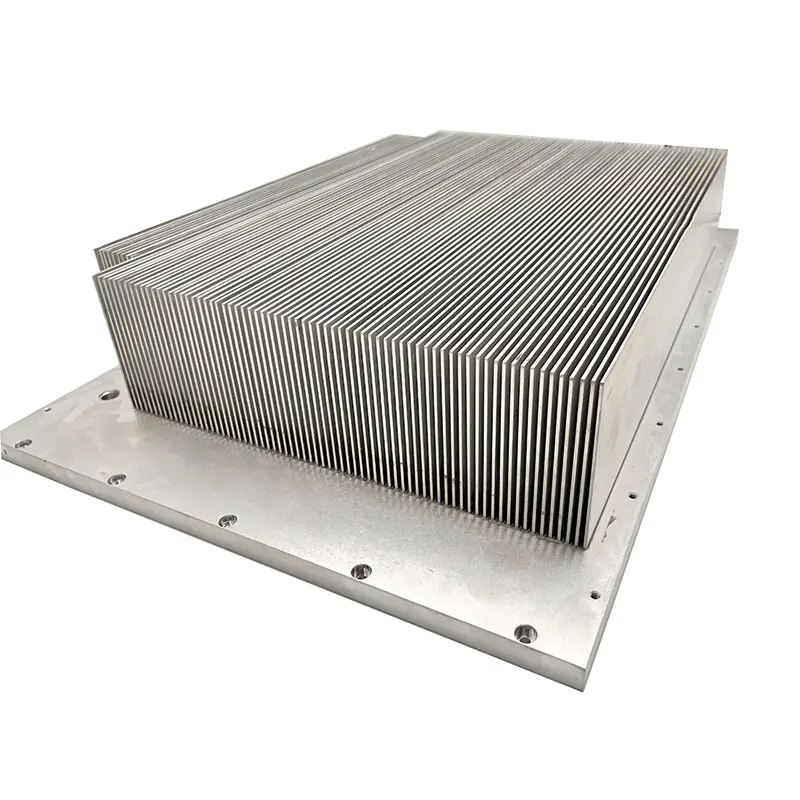

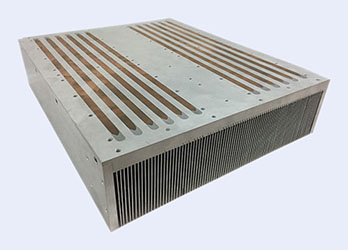

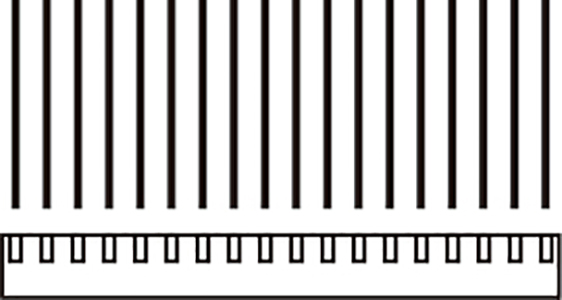

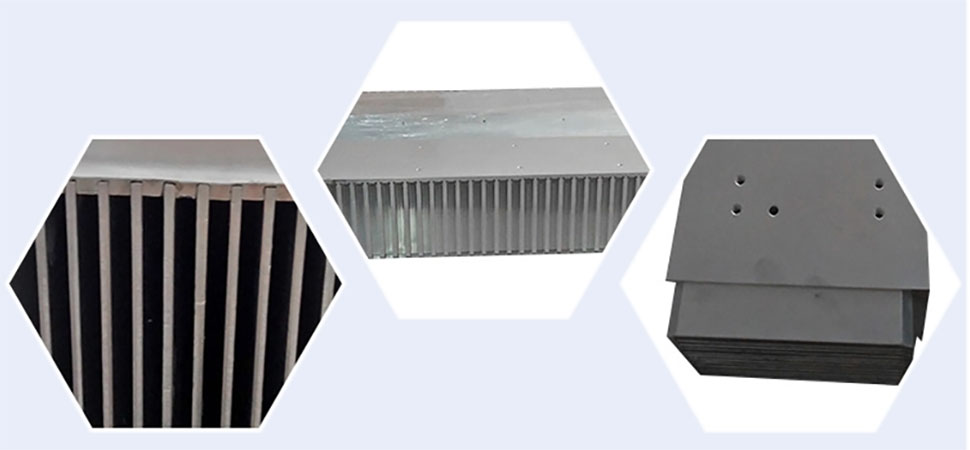

| Process: | Bonded fin | Shape: | Square |

| Material: | copper heat pipe+AL6063 | Brand Name: | LORI |

| Packing: | Standing Export Packing

| Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | LR0096 | Tolerance: | 0.01 mm |

| Finish: | Clean+Conductive anodizing | Quality control: | 100% thermal test |

| Extra process: | CNC Machining | Size: | 460*390*49mm |

| OEM: | Yes |

|

|

| Applied Field: | Thermoelectric modules,Uninterruptable power supplies (UPS)Variable speed motor controls AC welding switches Power rectification equipment Laser power supplies Traction drives |

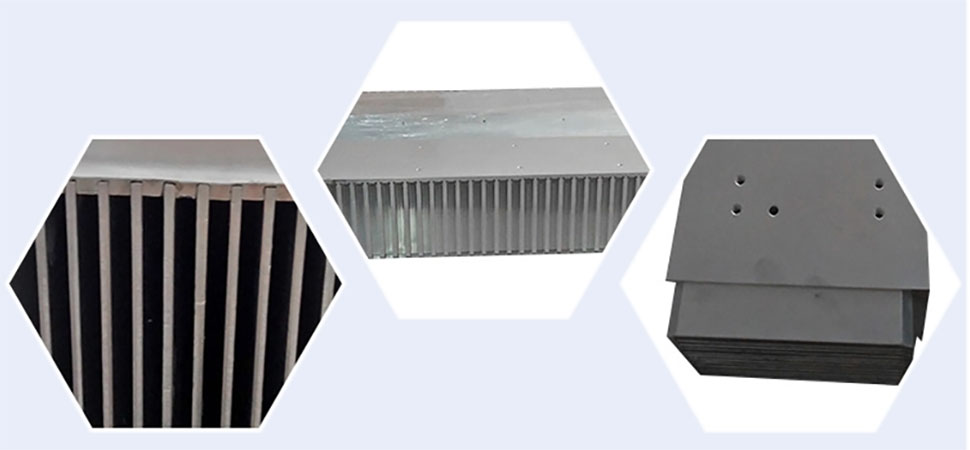

◪ This Large Bonded fin heat sink is made by aluminum base with individual aluminum fins bonded into the grooves. Bonded fin technique is a conventional high power heat sink manufacturing technique. We developed several bonding techniques via our own technical innovations and these include highly conductive thermal epoxy bonding, brazing, and soldering so as to greatly enhance the reliability and stability of cooling and avoid any potential risk. the aluminum/copper bases can be extruded, die cast, or machined. Fins are either punched from coil stock or cut from thin plate stock.

◪ Bonded fin heat sinks improve thermal performance because the fabrication allows for higher fin densities and fin aspect ratios .

Also bonded heat sink have lower tooling costs because we just need open the tooling for the grooved base or machined the grooved base.

Other benefits are no limit on length of airflow ,wide range of material and fabrication options and so on .

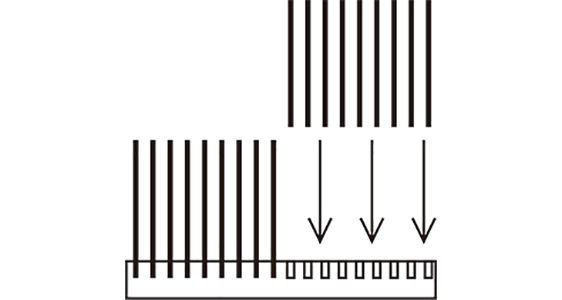

Prepare aluminum/copper base and fins according to the design drawings and create Grooved bases.

The fins and bases are joined together by epoxying, brazing or soldering.

Machining and surface treatment on the base and fins so as to form the bonded fin heat sink

Large Bonded fin heat sink can be applied to Welding Devices, Motor Devices, High Power Semi, Lasers System, Renewable Energy, Factory Automation, etc.

◪ In order to ensure the best service to the customer , we have formulated this after-sales service system, the company solemnly to the users of after-sales service work to do the following commitment:

◪ 1.Provide online technical support for customers, and provide consulting services on related issues

◪ 2.From the date of spontaneous delivery, if there is any quality problem or quality objection to our company's customized products, please contact with us in time. After checking and coordinating, we can return and replace the products in time.