In our current life, the application of laser instruments and equipment has been very extensive, in the industrial electronics applications including laser marking, laser cutting, laser welding, etc., in addition to the medical industry, the application of laser instruments and equipment is also very wide, such as oral laser treatment instrument, laser eyebrow washing instrument, laser skin beauty instrument, etc., which greatly facilitates our life.

Whether it is industrial or medical industry, the application of these laser instruments and equipment has played a good role in promoting social development, and as users and producers of these equipment. Although there is a sophisticated technology, but also for some small problems and trouble, especially the heat dissipation problem, extremely important, because the use of laser equipment for a long time, will certainly produce a lot of heat, heat dissipation is a problem that must be solved.

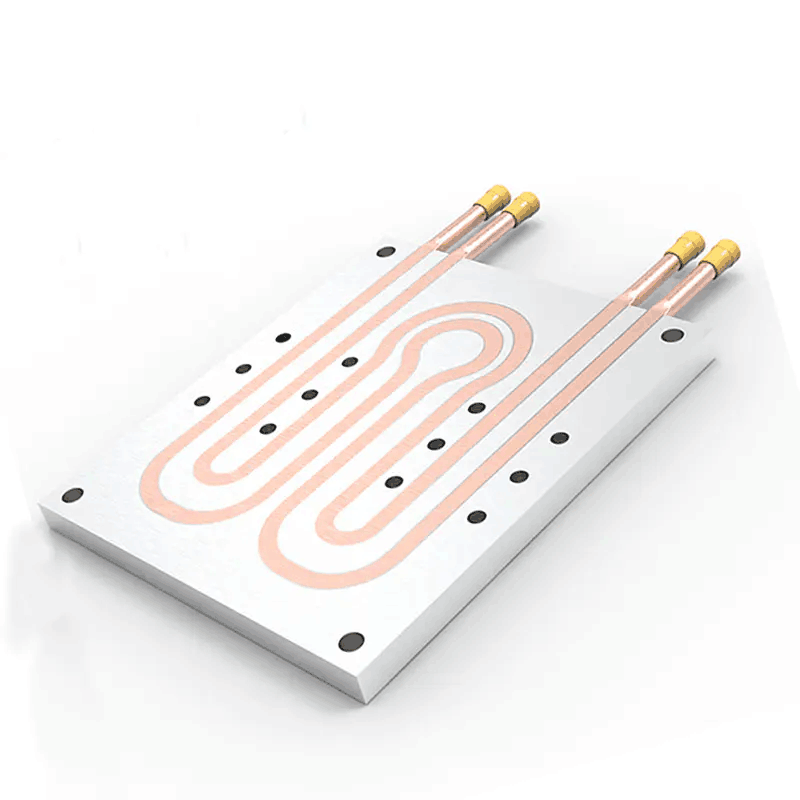

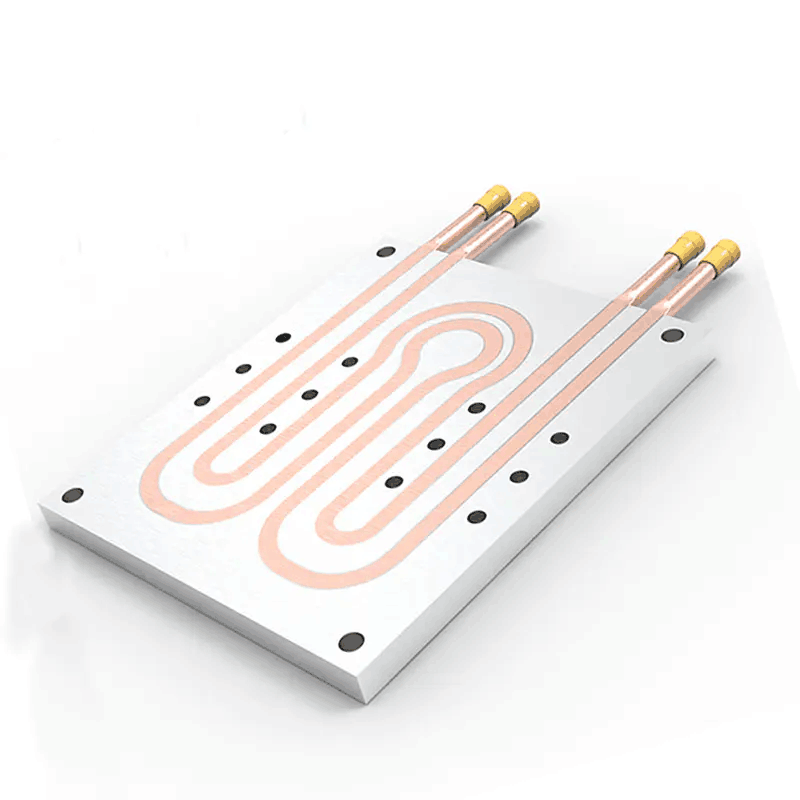

We take semiconductor lasers as an example, 50w needs to use cooling capacity of more than 1200w radiator equipment. Air-cooled heat sinks use air flow to dissipate heat, and in the case of forced convection, the heat transfer coefficient of air is 20-100w/㎡▪k, and the heat transfer coefficient of water is 1000-15000w/㎡▪k, that is, the same temperature and the same area, the heat transfer of water is dozens of times that of air. If you use air cooling to achieve the same heat dissipation efficiency, you can only increase the speed, but also increase the noise. In fact, whether from a professional point of view, or the trend of heat dissipation solutions, to heat laser equipment, choose liquid cold plate is a better solution.