- AI Thermal Management Solution

- Energy Storage System Thermal Management Solution

- Laser Thermal Solution

- Wind Power Converter Cooling Solutions

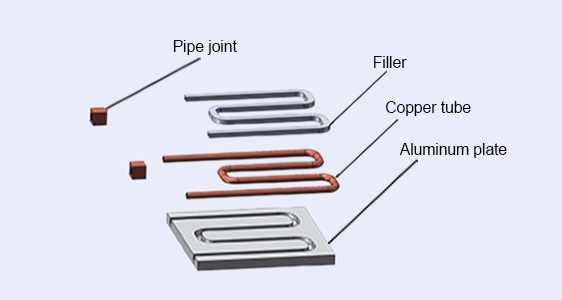

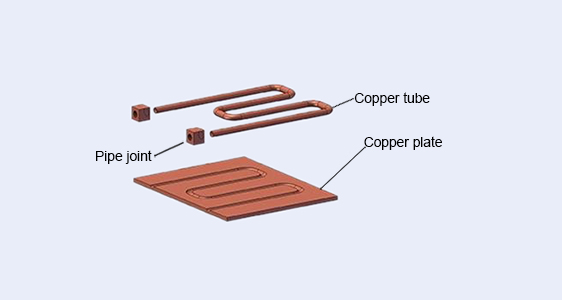

- Power Battery Cooling Solution

- Power Quality SVG Cooling Solution

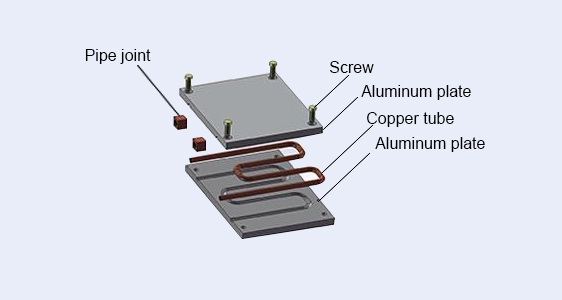

- EV Controller Cooling Solution

- Energy Storage Inverter Thermal Solution

- Inverter Cooling Solution

- Data Center Cooling Solutions

- Motor Housing Thermal Solutions

- 5G Thermal Solutions

- Robot Cooling Solutions

- PTC heater solution

- Photovoltaic Inverter Thermal Solutions

- Data Center Cooling Solutions