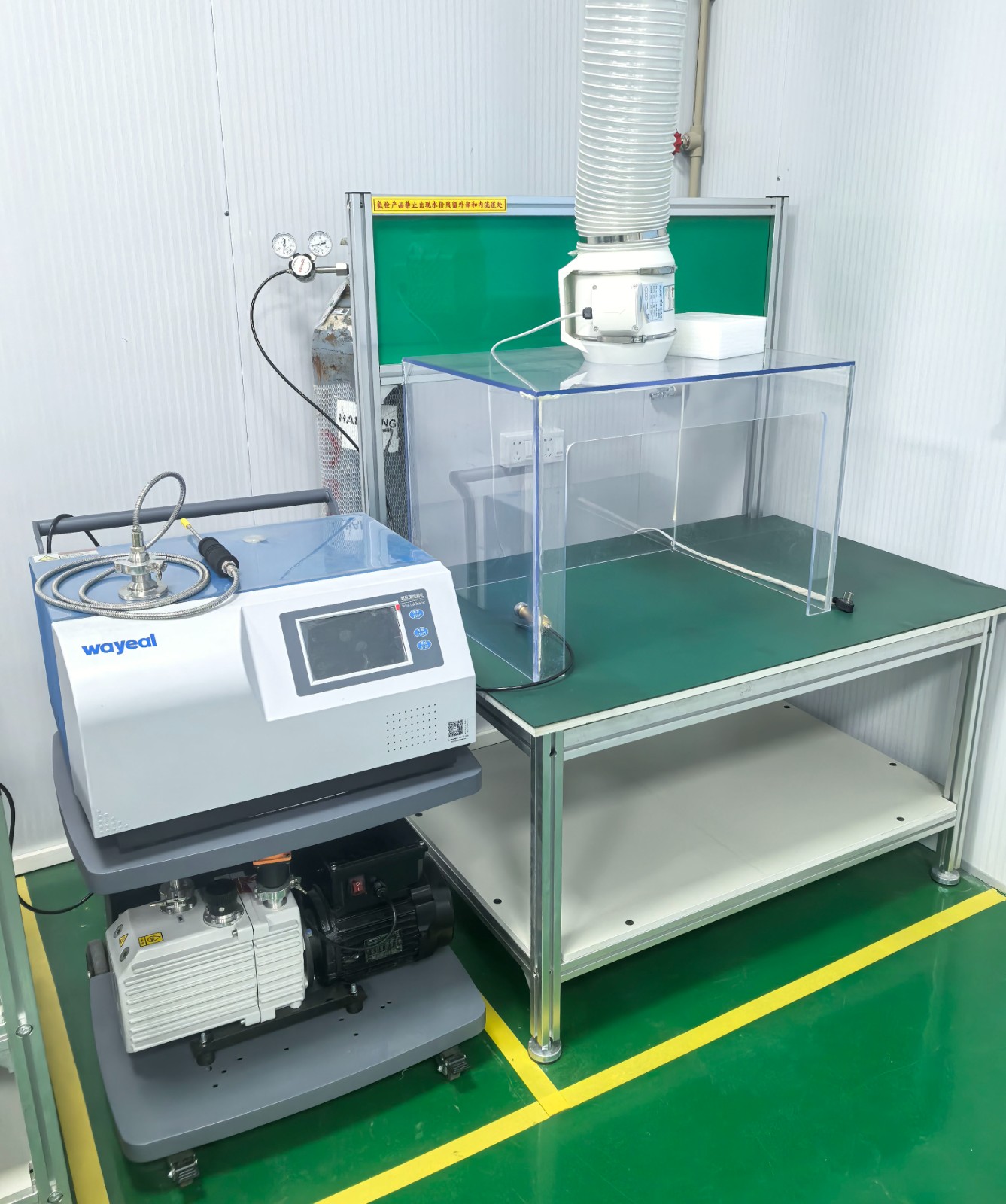

Leakage detection in Lori vacuum brazing liquid cooling loops utilizes vacuum technology and the unique properties of helium for high reliability, ensuring no leakage risk in our liquid cooling.

- Laser Thermal Solution

- Wind Power Converter Cooling Solutions

- Power Battery Cooling Solution

- Power Quality SVG Cooling Solution

- EV Controller Cooling Solution

- Energy Storage Inverter Thermal Solution

- Inverter Cooling Solution

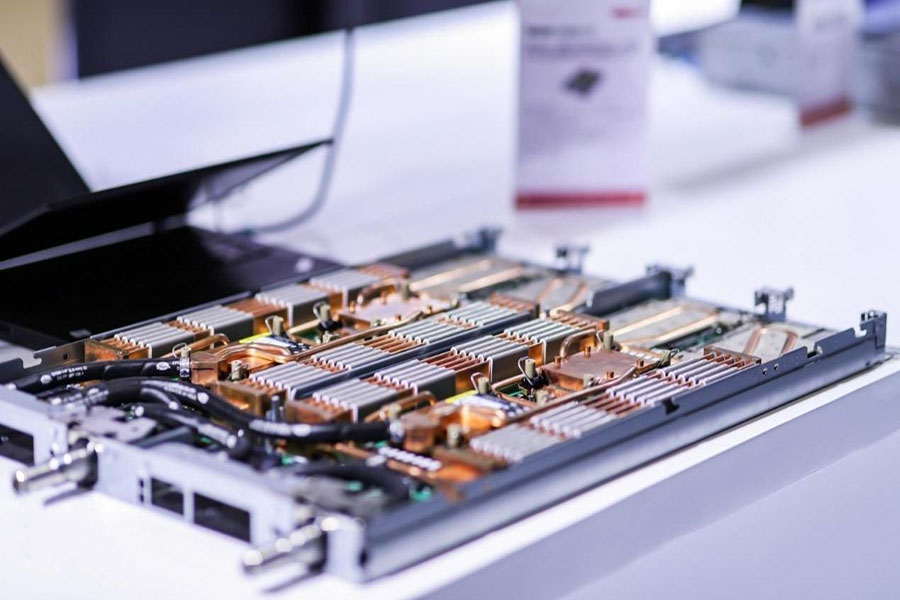

- Data Center Cooling Solutions

- Motor Housing Thermal Solutions

- 5G Thermal Solutions

- Robot Cooling Solutions

- PTC heater solution

- Photovoltaic Inverter Thermal Solutions

- Data Center Cooling Solutions