The battery pack is a key component of electric vehicles, and power batteries are sensitive to temperature changes. During the charge and discharge process, new energy vehicle power batteries generate a significant amount of heat. If the temperature gets too high, it may affect the battery's lifespan and even cause accidents. To extend the battery's service life and range, effective cooling is essential.

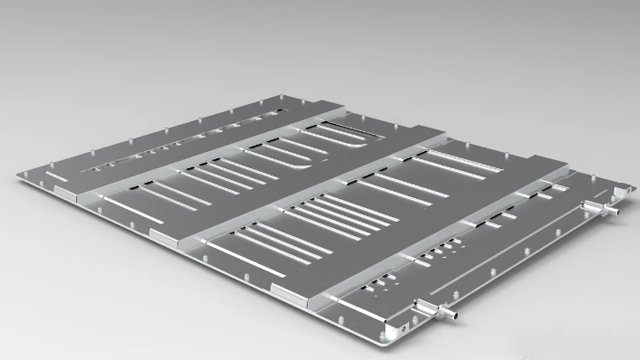

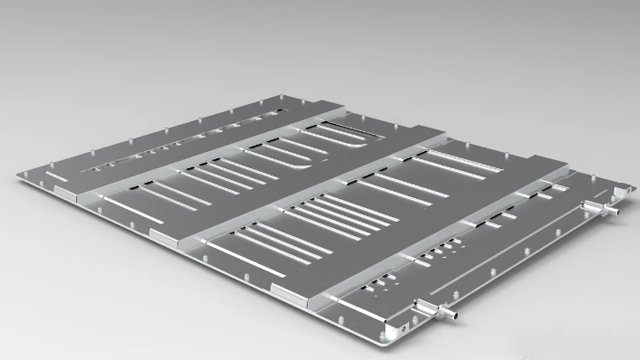

Currently, liquid cooling is the mainstream cooling method. A water-cooling plate placed between two battery cells can reduce heat transfer between adjacent cells, preventing thermal runaway in a single cell from causing a chain reaction in the entire battery, thereby enhancing battery safety. Automotive water-cooling plates can use aluminum brazing composite materials, typically made from upper and lower O-tempered aluminum plates brazed together, ensuring the stability and safety of power batteries in high-temperature operating environments.

Performance Advantages of 3003 Aluminum Plates for Automotive Water-Cooling Plates The 3003 aluminum plate, used for manufacturing water-cooling plates, belongs to the aluminum-manganese alloy series. This material meets requirements for corrosion resistance, processability, and other aspects, while also satisfying the design and application requirements for water-cooling plates. Aluminum alloys offer multiple advantages including low cost, lightweight, good machinability, and corrosion resistance. Moreover, aluminum materials have better brazing properties than copper, making aluminum brazing composite materials an important part of thermal management systems.

High Quality Requirements for 3003 Aluminum Plates Used in Automotive Liquid-Cooling Plates The importance of thermal management systems for battery safety cannot be overstated. Accordingly, the requirements for 3003 aluminum plates used in water-cooling plates are high, with specific demands on alloy composition, mechanical properties, and other aspects. Raw material manufacturers must strictly control these factors to produce qualified products.

In recent years, with the explosion of the new energy battery industry, the demand for water-cooling plates is also expected to grow exponentially. Lori, a large aluminum plate manufacturer, has successfully developed aluminum alloy composite materials for water-cooling plates and has achieved mass production. The 3003 aluminum plates for new energy vehicles are produced in strict accordance with relevant standards, with customizable sizes, high processing precision, and original factory quality assurance, ensuring stable and reliable product performance.