| Place of Origin: | Shenzhen, China (Mainland) | OEM: | Yes |

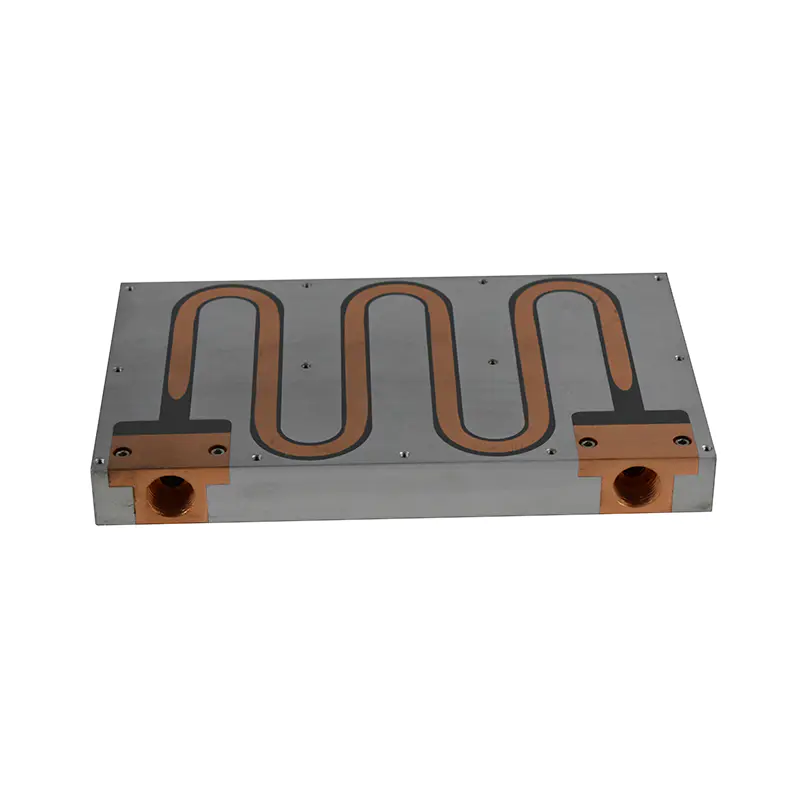

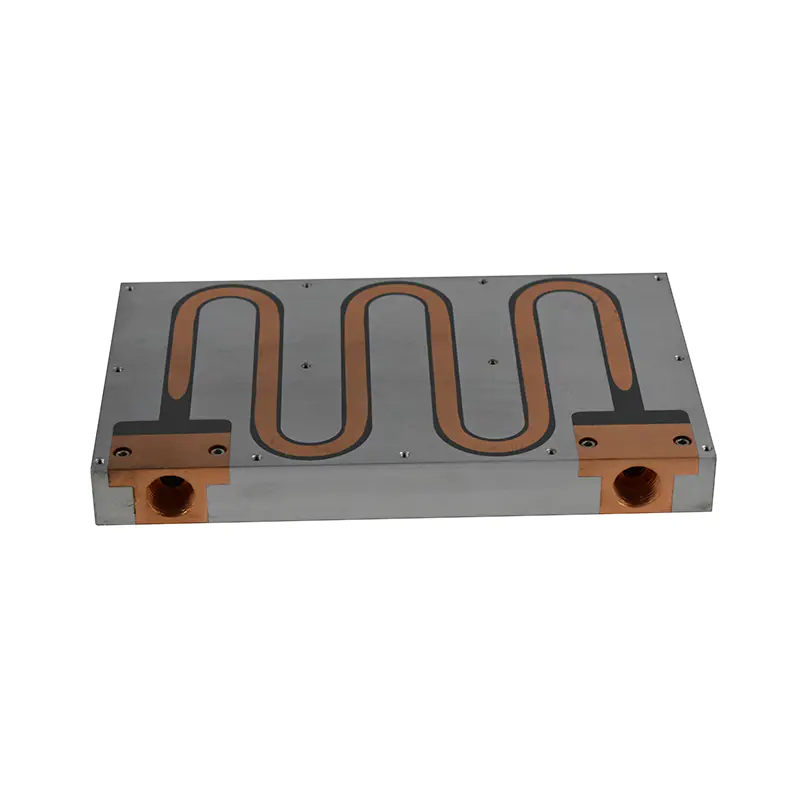

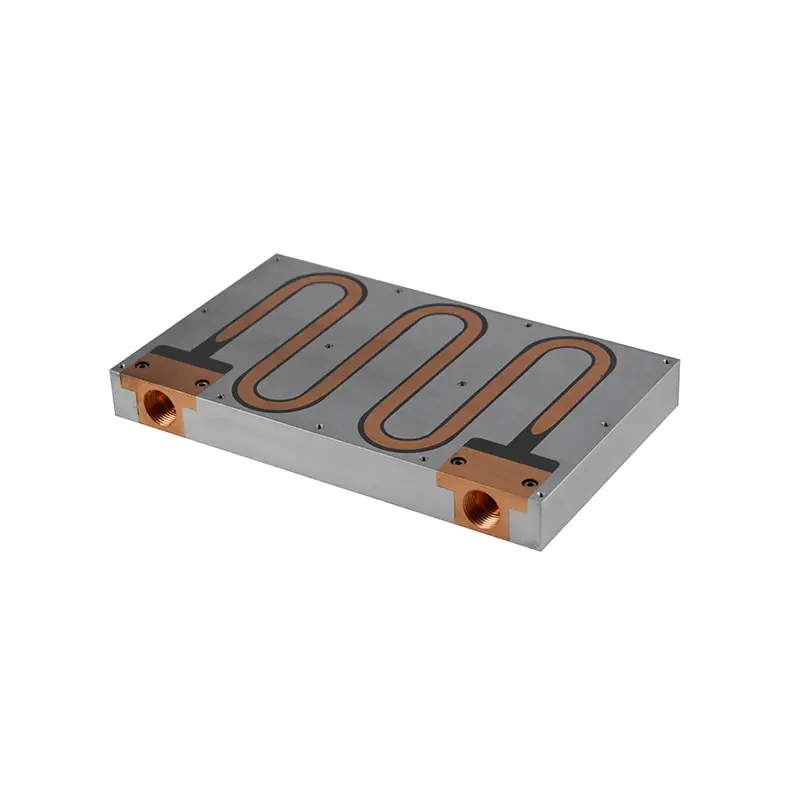

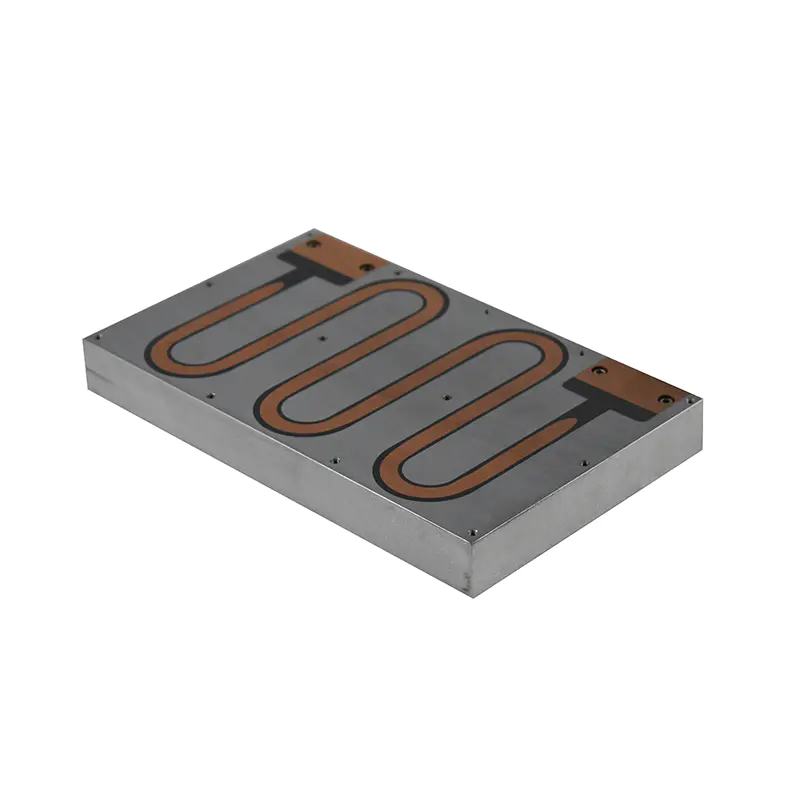

| Process: | Epoxy Bonding | Temper: | T3-T8 |

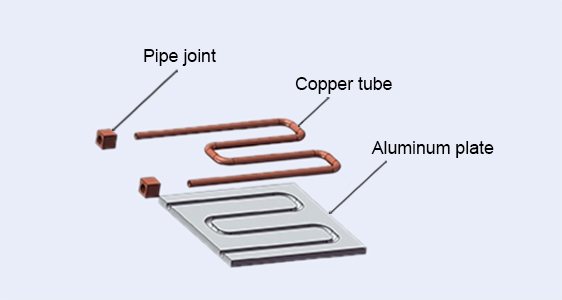

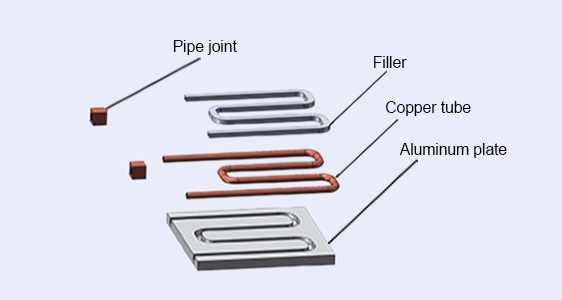

| Material: | Copper heat pipe+ AL plate | Shape: | Square |

| Packing: | Standing Export Packing

| Brand Name:

| LORI

|

| Application: | RGB laser light source | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | LR0019 | Tolerance:

| 0.01 mm |

| Finish: | Clean+Anodized | Quality control: | 100% thermal test |

| Extra process: | CNC Machining | Size: | Custom size |

| Applied Field: | New energy automobile , UPS and energy storage system , large server, large pv inverter , SVG/SVC , etc |

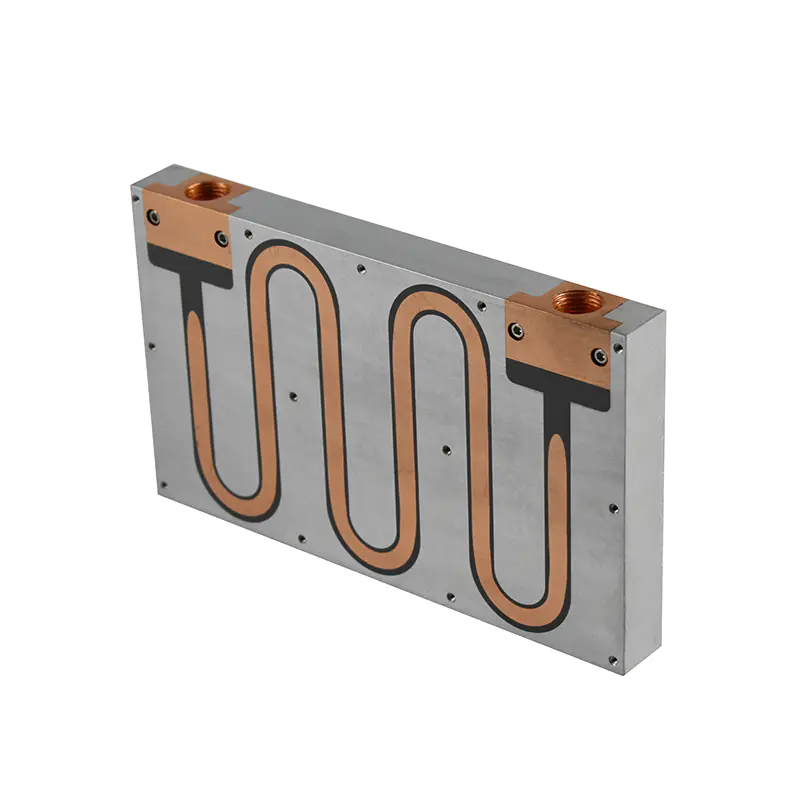

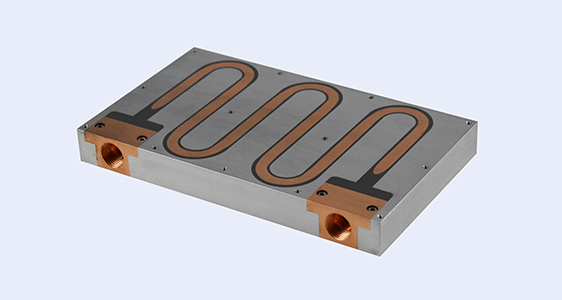

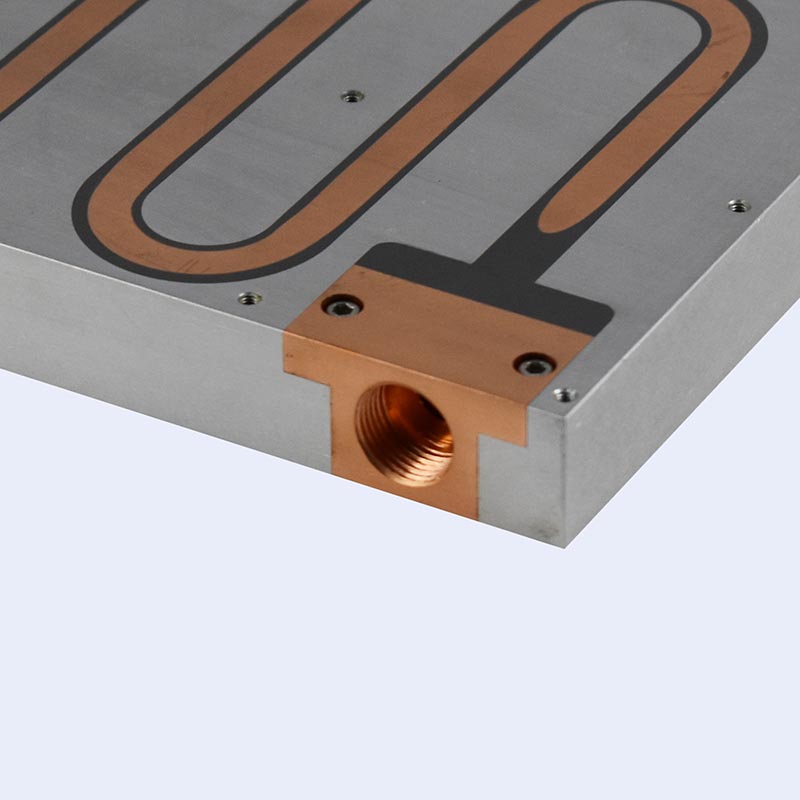

The water cooling heatsink made using buried welding technology can effectively avoid the leakage risk of the infusion pipeline, and the liquid flow is large, the conduction heat resistance is low, and the double-sided device can be installed. we are providing you with the thermal design, structural design, pipework assembly design of liquid and water cold plate and one-stop supplementary services.

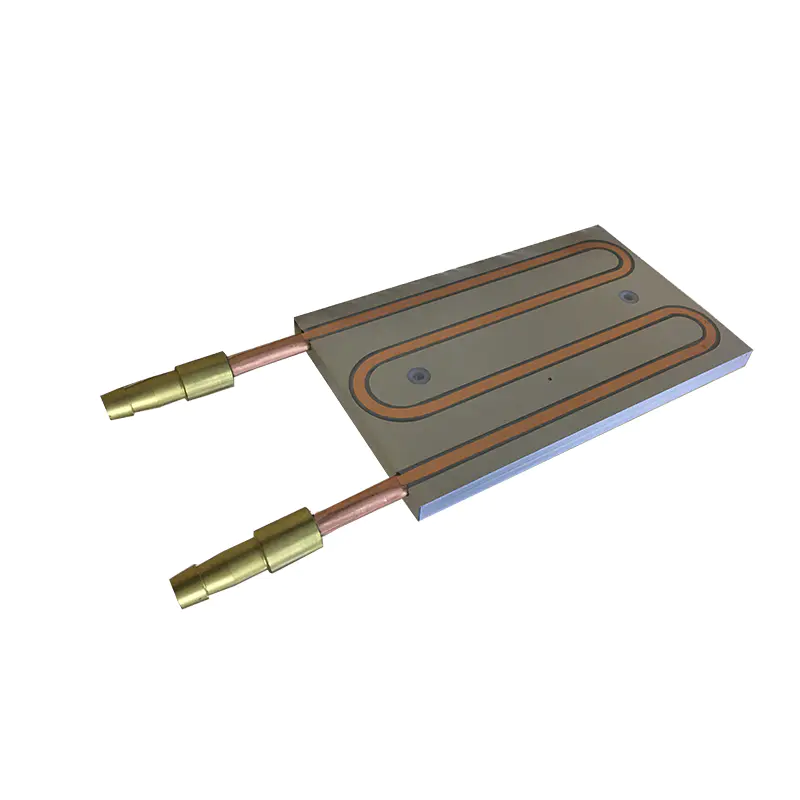

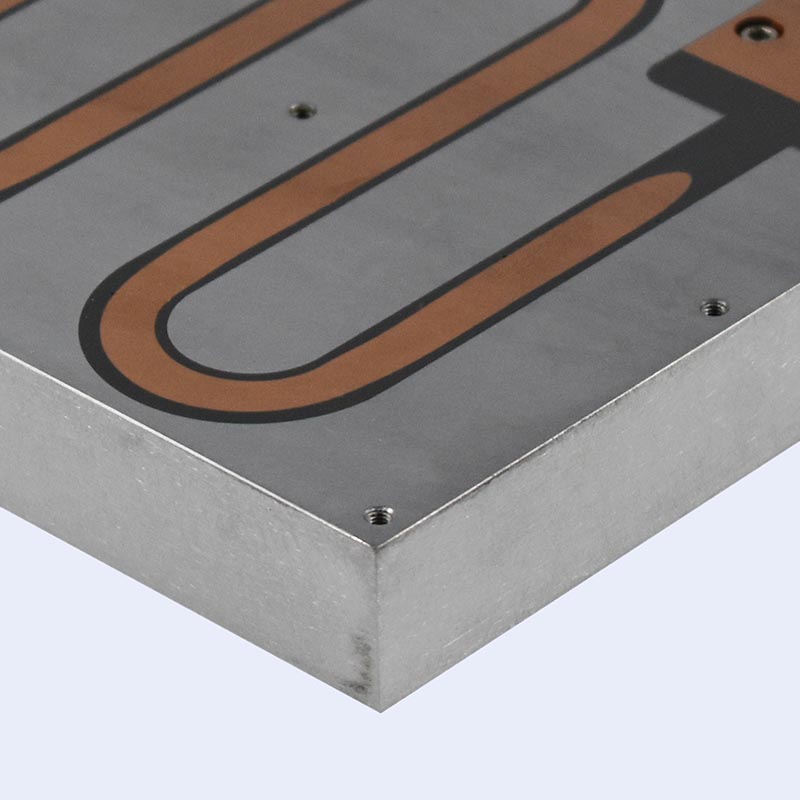

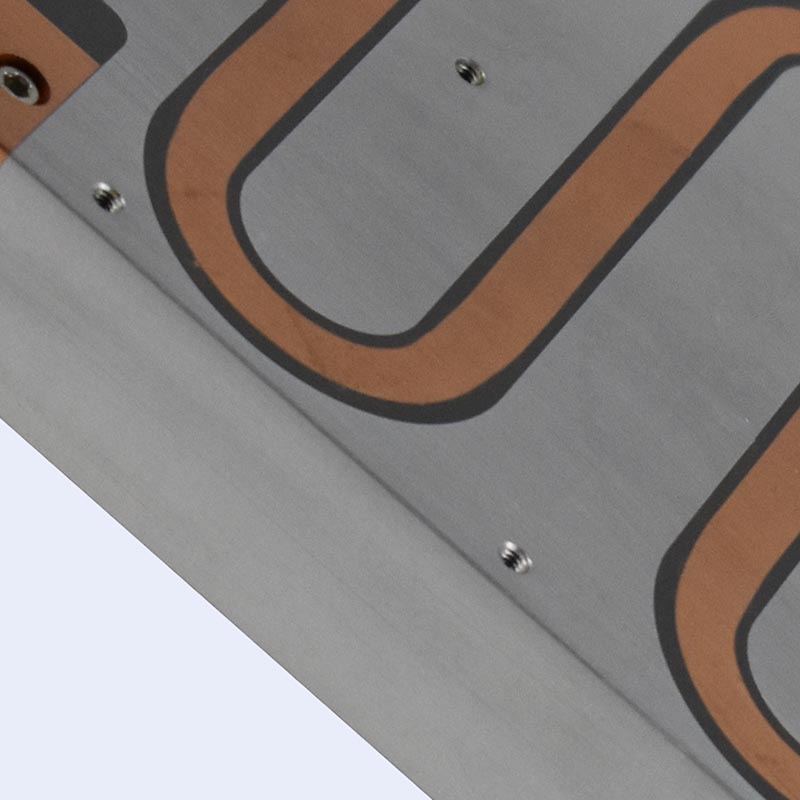

Exposed-tube technique: This technique applies to devices to be installed on one side. Copper tubes are pressed to deform into the grooves within an aluminum plate and then a fly-cut is applied to the surface. This allows the quick removal of heat due to the high thermal conductivity of copper tubes. Meanwhile, the lightweight of aluminum can reduce the total weight and keep the cost to a reasonable extent.

Full-buried-tube technique: The filler is a type of highly conductive epoxy resin which is imported from the US. When the temperature difference between two sides of a device is not critical, the cold plates can be applied to either just one side or both sides of the device. Since the copper tube thickness is not affected by any secondary machining and the application safety is ensured due to the protection of the filler, this technique is especially suitable for cold plate applications which use refrigerant as the cooling medium.

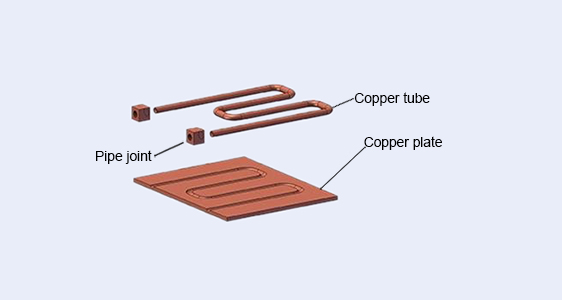

Half-buried techniques: This technique is suitable for the combination of copper plate + copper tubes. It can reduce the plate thickness and generate the weight reduction effect.

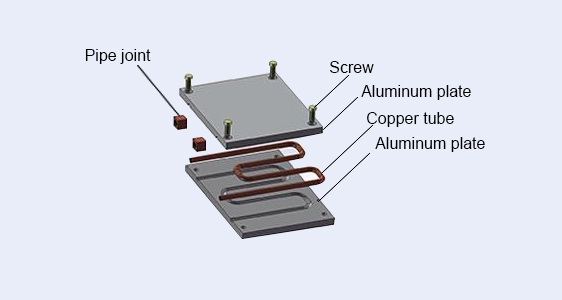

Sandwiched-tube technique: There are tubes between two plates and this technique is simple with lower cost. The combination could be aluminum plate + aluminum tubes/copper tubes/SUS tubes.

As a mature cooling technology, water cooling heat sink has been widely used in industrial ways, such as automobile and aircraft engine cooling. In fact, the application of liquid cooling technology in the computer field is not because air-cooling cooling has been developed to the end, but because the heat sink speed of liquid is far greater than that of air, so the water cooling heat sink often has a good cooling effect, at the same time in the noise can be well controlled. Due to various advantages in heat dissipation efficiency and mute, water cooling heat sink also appeared after the popularity of computer air-cooled heat sink. Fortunately, up to now, water cooling in the field of computer is gaining popularity, which is attributed to the safety and stability of liquid cooling heatsink has made great progress.

Requirements for water cooled heat sink for high power device

Water cooled heat sinks have high heat dissipation power, applicable to many fields, such as new energy, etc. Lori has a lot of customers are in the field of new energy enterprises, their power battery products will use our water cooled heatsink, this kind of customer requirement for liquid cooled heat sink mainly include:

1. High heat dissipation power

The excess heat generated during the operation of the power battery can be timely derived to avoid excessive temperature rise

2. High reliability

To work in the road traffic environment, vibration, shock, high and low temperature alternating environment, for most products are relatively harsh working conditions, and the power battery voltage at a few hundred volts, cooling fluid leakage is a serious problem, even if you use insulation good cooling fluid, but after meet external impurities, insulation performance would immediately reduce, therefore, cold plate seal reliability is very important.

3. Accurate heat dissipation design

Avoid excessive temperature difference in the system, which is due to the requirements of lithium battery performance, battery performance and aging are closely related to the operating temperature

4. There are strict requirements on the weight of the water cooled heat sinks

This comes from the power battery system's pursuit of energy density, which seriously lowers the cooling system's energy density, which is unacceptable to both the customer and the designer.

Lori is one of professional liquid cold plate manufacturers , our water cooling, liquid cooling heat sink series products to the above requirements can be very good to meet, we provide long-term users with safe and efficient water cooled heat sink design, if you need further understanding, you can directly contact us.