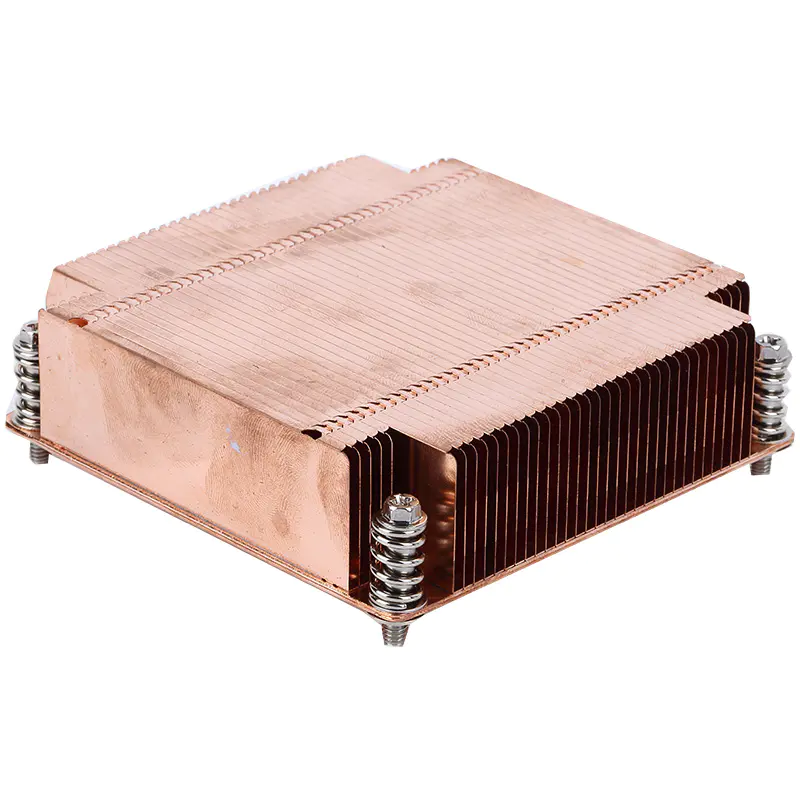

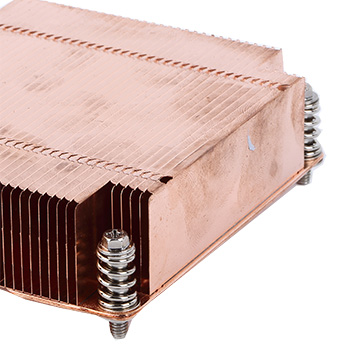

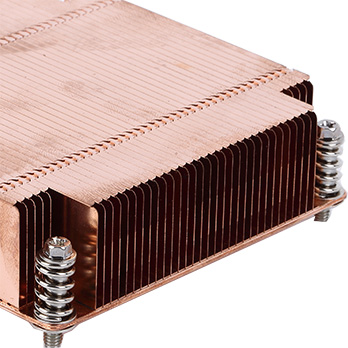

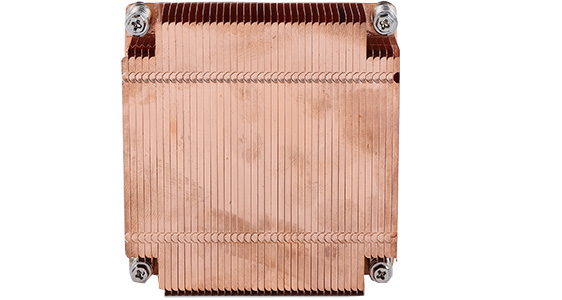

Copper heat sink for welding advantages as following

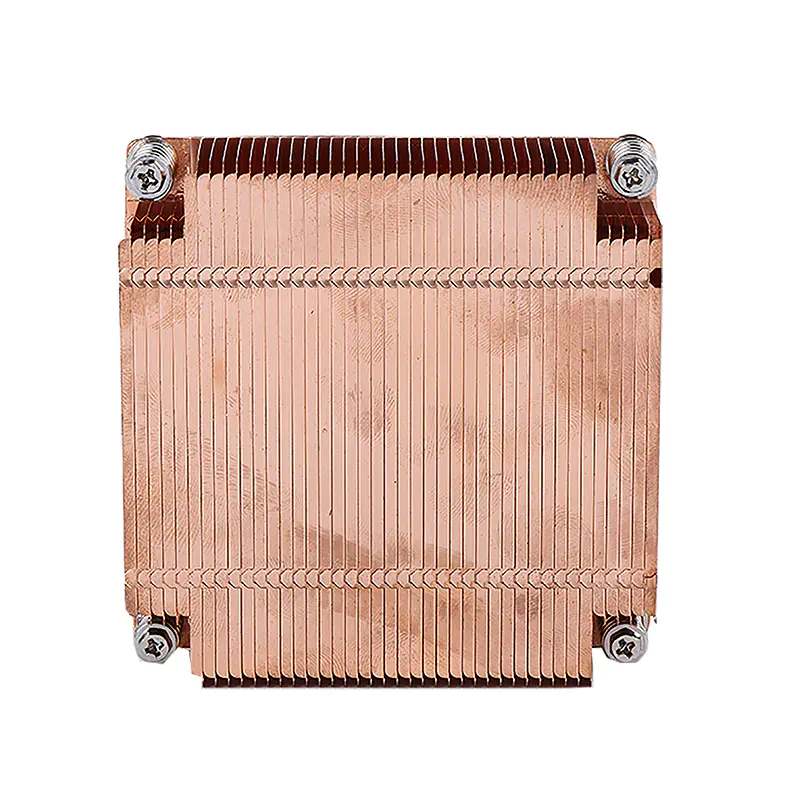

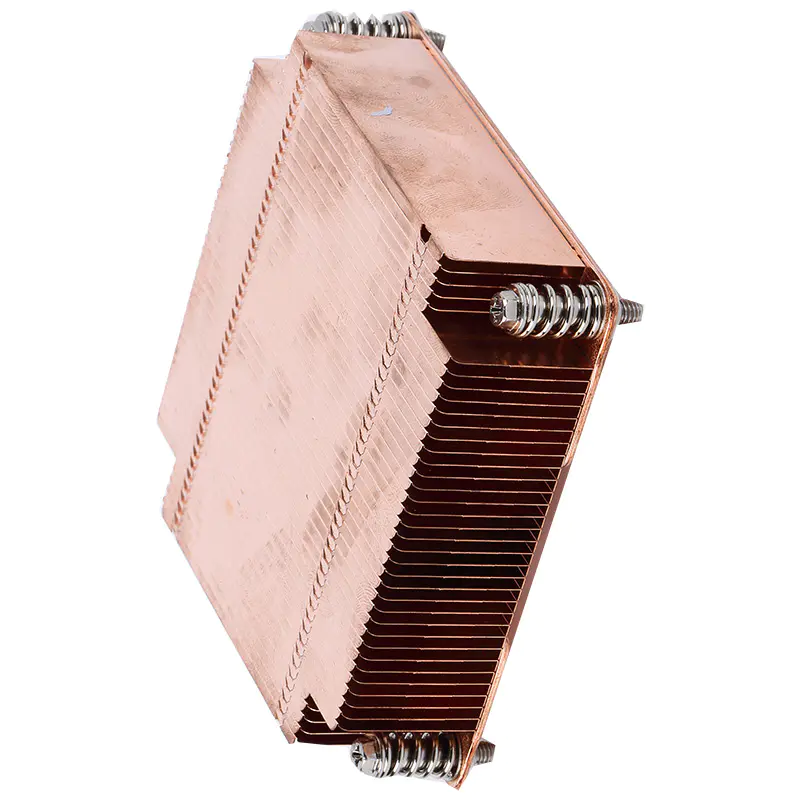

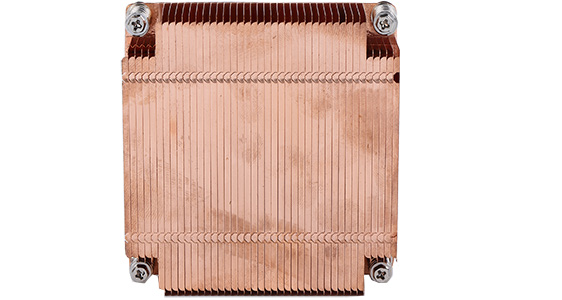

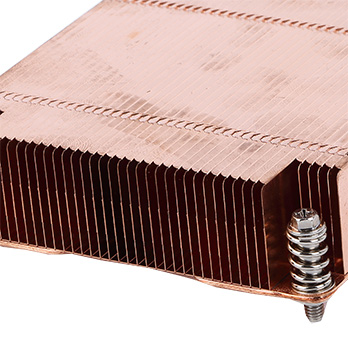

1. High density fin, heat dissipation area, light weight. For soldering single fin, the groove can be processed on the bottom plate to insert the fin into the groove for welding. The density of the fin can be up to 1mm and the height can be up to 150mm.

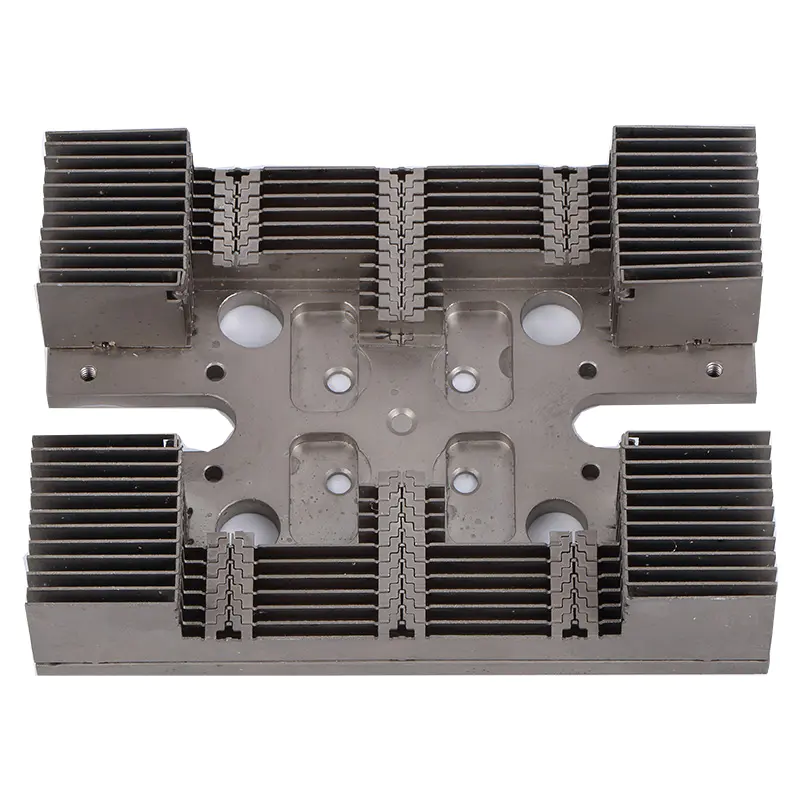

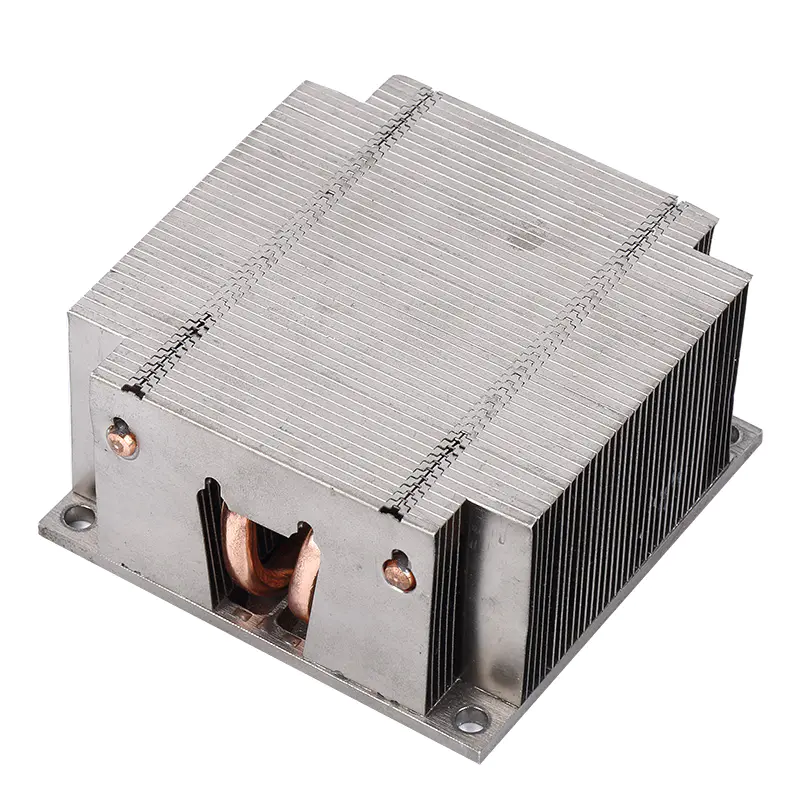

2. The plate can be machined in a complex way, and can be embedded with heat pipes or vampor chamber, greatly increasing the average temperature.

3. The surface of copper welding heat sink will not be oxidized by medium temperature machining.

4. The welding heat sink copper shape is flexible, which can easily process, install hole position and device avoiding position.

5. Low mold cost, from mini heatsink to large heat sink can be quickly mass production.

6. High reliability, has been widely used in IT equipment and communication equipment heat dissipation.

7. For surface treatment, copper can be welded only after nickel plating, red copper can be welded after rust and oil removal