BLT-GBP05-1-G liquid cold plate pneumatic leak test equipment is a new type of gas pressurization device developed by our company based on the working principle of the imported pneumatic pressure boost and test device from abroad, and in combination with the actual situation in our country.

Characteristics

This gas pressure testing equipment uses pure compressed air as the driving power source, with a gas booster pump as the pressure source, and uses pure gas as the pressurized medium. The output gas pressure is proportional to the driving air source pressure. By adjusting the driving air source pressure, the corresponding pressurized gas pressure can be obtained. When the driving air source pressure and the pressurized gas pressure reach equilibrium, the pneumatic booster pump stops boosting and the output gas pressure stabilizes at the pre-adjusted pressure. Therefore, it has the characteristics of explosion-proof, energy-saving, environmental protection, adjustable output pressure, small size, light weight, simple operation, reliable performance, wide application range, etc.

Application

Used for air pressure tests of liquid cooling plates products, as well as gas pressure boost tests and other applications.

Model Significance

1. ( BLT ) The product code indicates that this device is a pressure boost leakage detection system.

2. (GBP05) indicates that the pressure ratio of the gas booster pump GBP05 used in this device is 5:1.

3. (1) This indicates that the device has 1 test outlet.

4. (G) Indicates that the pressurizing medium is specifically for gases.

Equipment Composition

The leak test machine is composed of a gas booster pump, air pressure reducing valve and filter, automatic high-pressure stop valve, automatic high-pressure decompression valves, stainless steel pipelines, high-pressure pressure gauges, drive pressure gauges, PLC control system, touch screen, sealed box, and customized testing area, etc.

Function Information:

◪Test pressure range: 0 - 4 MPa

◪Single-channel independent testing. The pressure of the single channel can be freely adjusted to the set pressure value.

◪Equipment dimensions: Length 185cm x Width 120cm x Height 165cm

◪Test tank: Length 122cm x Width 111cm x Height 30cm

◪The equipment body is equipped with swivel casters (adjustable fixed columns).

◪With blast test chamber door protection, equipment shape and color (Look at the picture below.)

◪7-inch touch screen + alarm

The approximate appearance diagram of the equipment is as follows

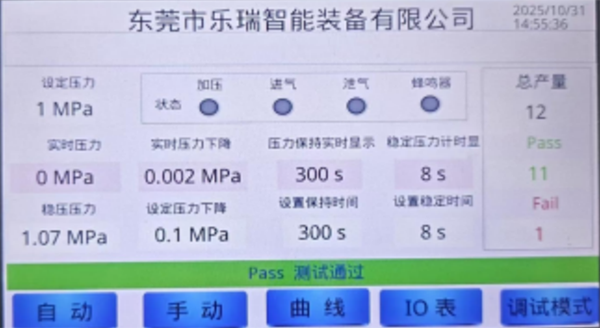

The interface diagram of the equipment operation is as follows: Chinese operation page

The BLT series pneumatic booster pumps use a single pneumatic control non-balanced gas distribution valve to achieve the reciprocating motion of the pump, which are all made of aluminum alloy and stainless steel, and all the sealing components are imported high-quality products. The maximum designed driving air pressure is 10 bar. To ensure the pump's lifespan, it is recommended that the driving air pressure be ≤ 8 bar. The driving piston diameter of this series of pumps is 160mm, and it is a double-head double-acting pump.

Main technical parameters of the single-channel liquid cooling plate air pressuer testing equipment:

| Actual boost ratio | 5:1 |

| Maximum output pressure | 40 bar (0 - 580 psi) (when the driving pressure is 8 bar) |

| Entry pressure range | 1 - 40 bar |

| Exit pressure range | 8 bar - 40 bar (adjustable) If the test pressure is lower than 8 bar, the intake pressure in the workshop needs to be adjusted to be lower than the test pressure |

| Maximum exit flow rate | 510 NL (standard flow rate per minute when the inlet pressure is 6 bar) |

| Driving pressure requirement | 1 bar - 8 bar (Customer to provide) |

| Boost medium | Air, nitrogen |

| PLC control system | Automatic pressure retention, automatic pressure relief, independent control at each single station |

| Test water tank | Length 122 cm x Width 111 cm x Height 30 cm |