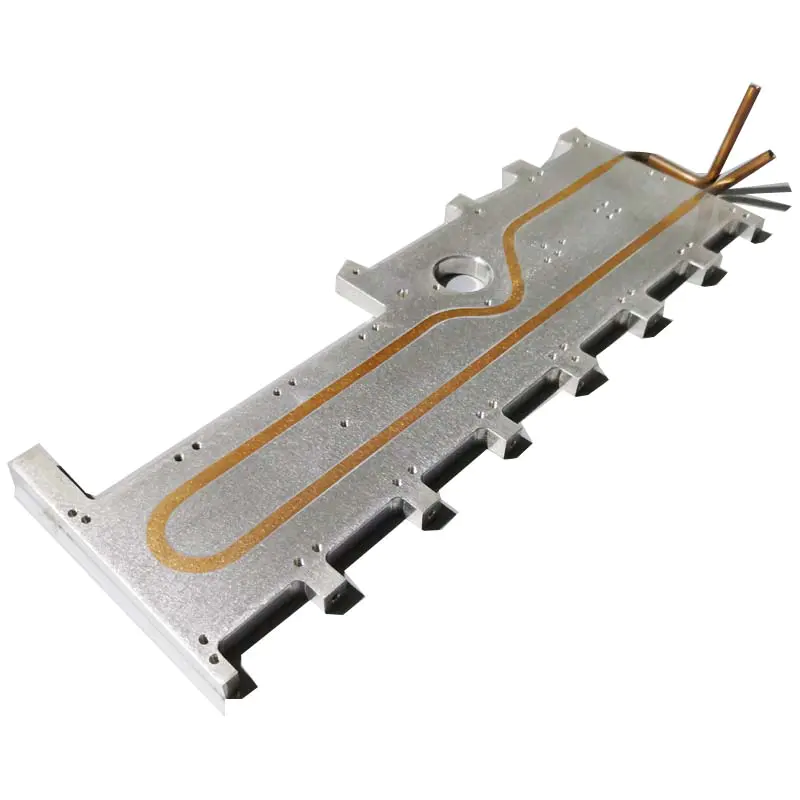

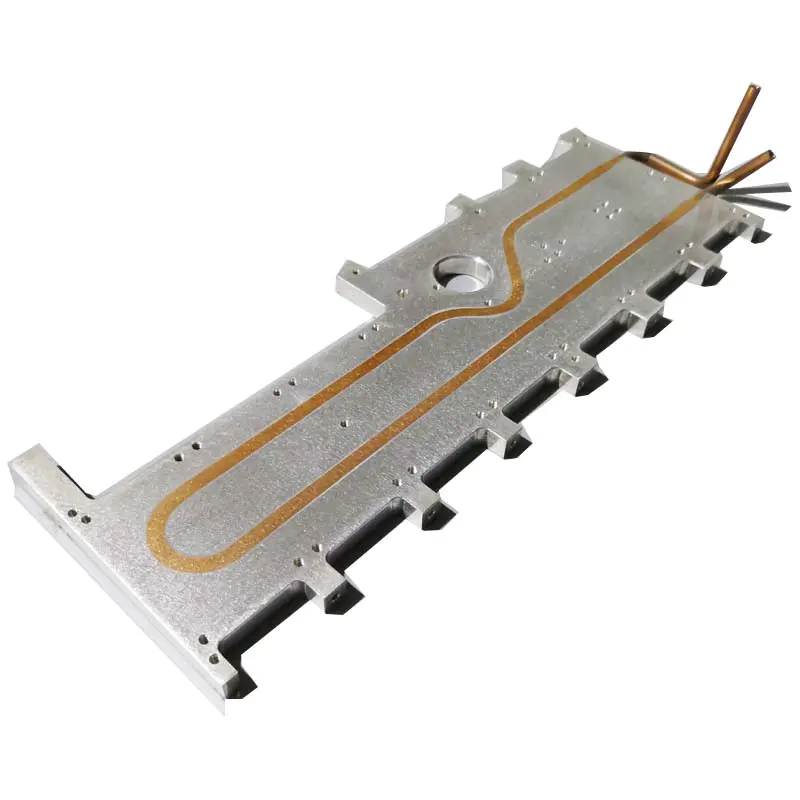

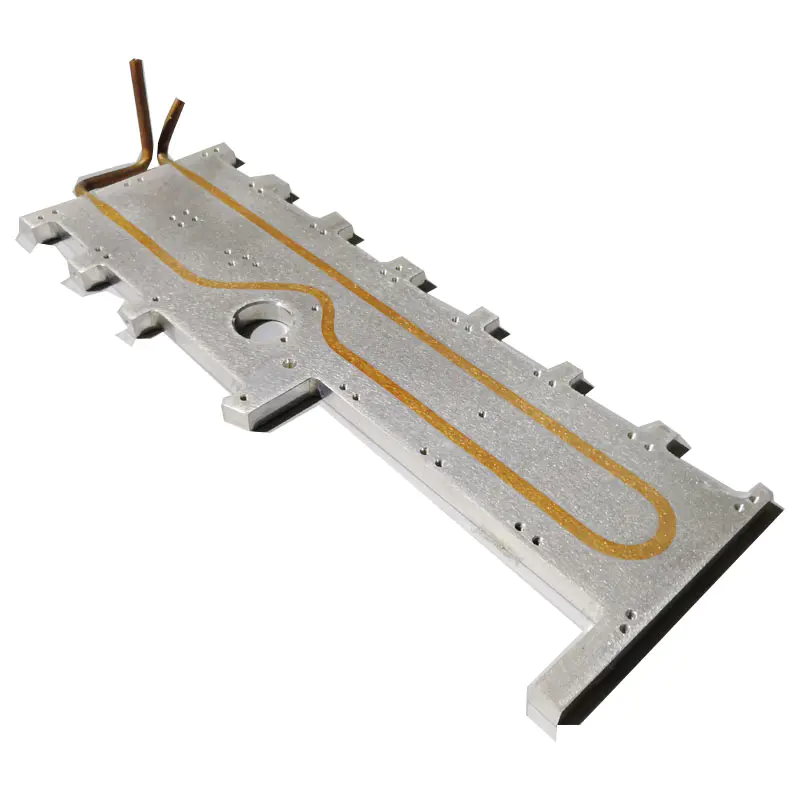

IGBT heat sink

| Place of Origin: | Shenzhen, China (Mainland) | OEM: | Yes |

| Process: | Profiles Extruding | Temper: | T3-T8 |

| Material: | AL 6063 T5 | Shape: | Square |

| Packing: | Standing Export Packing

| Brand Name:

| LORI

|

| Application: | IGBT inverter | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | IGHS002 | Tolerance:

| 0.01 mm |

| Finish: | Degreasing, Anodizing,Sand Blasting, | Quality control: | 100% thermal test |

| Extra process: | Cutting + CNC Machining(Milling, Drilling,Tapping) | Size: | 142(W)*71.5(H)*200(L)mm, or custom design |

| Max Aspect Ratio | More than 20 times aspect ratio heat sink can be extruded by 800 tons--5000 tons extruding machine by the most advanced technology |

| Max Width | Ultra wide extruded heat sink can be made by our unique friction welding technology |

| Sample Service | Samples with differernt sizes are availabe for prototypes test within 1-2 week |

| Production Process | Profiles Extrution---Cutting---CNC Machining(Milling, Drilling,Tapping), Deburring, Cleaning, Inspecting, Packing |

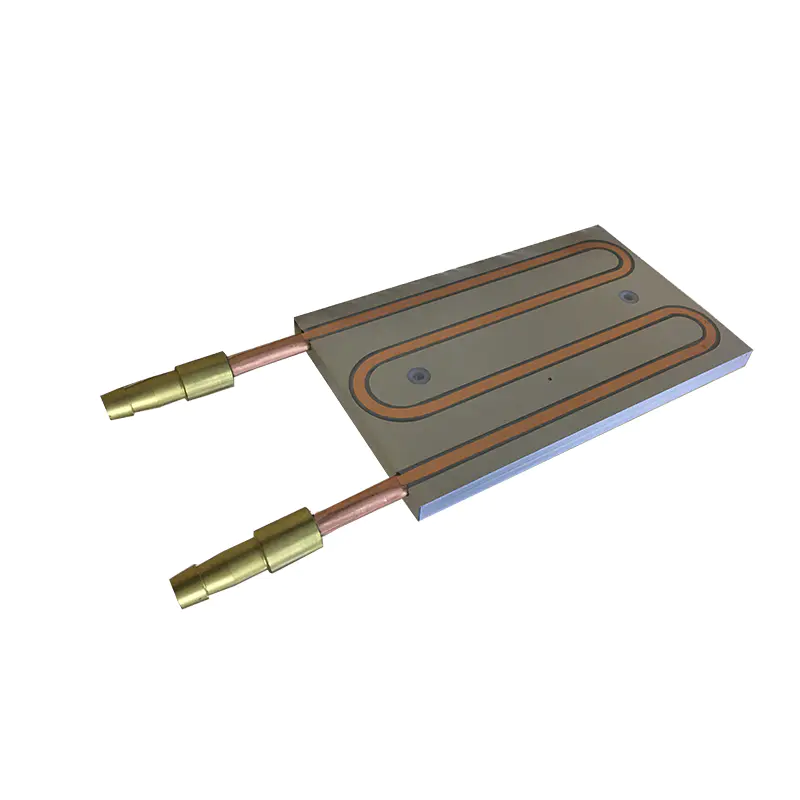

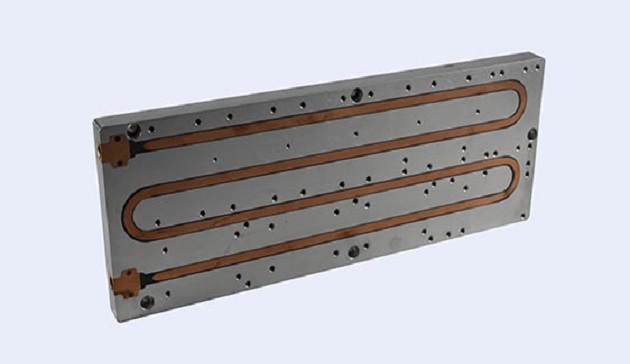

IGBT cooling system cold plate

The water cooled cold plate for IGBT modules made using buried welding technology can effectively avoid the leakage risk of the infusion pipeline, and the liquid flow is large, the conduction heat resistance is very low, and the device can be installed on the igbt cooling plate. we are providing you with thermal design, structural design, pipework assembly design of igbt cold plate and aluminium water cooled igbt cold plate and one-stop supplementary services.

LEDLighting, Inverter, Welding Machine, Communication Device, Power Supply Equipment, Electronic Industry, Thermoelectric Coolers/Generator, IGBT Cooling Systems,etc.

1. Cooling plate for high power rectifier (unique integral structure, strong and durable).

2. IGBT, IPM, Square semiconductor water cooling heat sink (good temperature uniformity, long life design)

3. Cooling plate for high power fiber laser, Electric Automobile, Optical communication, Military transmitter, Etc.

4. water cooling heat sink for LED Lighting, Inverter, Welding Machine, Communication Device, Power Supply Equipment, Electronic Industry, Thermoelectric Coolers/Generator, IGBT/UPS Cooling Systems,etc.

◪ In order to ensure the best service to the customer , we have formulated this after-sales service system, the company solemnly to the users of after-sales service work to do the following commitment:

◪ 1.Provide online technical support for customers, and provide consulting services on related issues

◪ 2.From the date of spontaneous delivery, if there is any quality problem or quality objection to our company's customized products, please contact with us in time. After checking and coordinating, we can return and replace the products in time.