In the planning and construction of data centers, the design of temperature control systems is particularly critical. It not only affects the stability of equipment operation but also directly impacts energy consumption and operational costs. As the core of temperature control, the selection of cooling methods for central air conditioning systems is especially important. Currently, the two most common cooling methods are cooling towers and dry coolers, which differ significantly in their principles, applicable scenarios, and operational characteristics.Fundamental Working Principles of Cooling Towers and Dry CoolersCooling towers operate as evaporative cooling equipment, utilizing the heat absorption effect of evaporation when water contacts air to dissipate heat. The specific process involves: high-temperature cooling water is delivered into the tower by pump, where a spray system atomizes it into fine droplets. These droplets undergo heat and moisture exchange with incoming air. Part of the water evaporates into vapor, absorbing substantial heat in the process and lowering the temperature of the remaining water. The cooled water is then recirculated back to the condenser of the refrigeration unit to complete the heat transfer cycle. This process relies on the latent heat of phase change in water, achieving high heat exchange efficiency and maintaining effective cooling performance even in high-temperature, high-humidity environments.Dry coolers are air-cooled devices, relying entirely on sensible heat exchange between air and the cooling medium to achieve temperature reduction. Refrigerant or cooling water flows through enclosed coils, while outdoor air is forced by fans to pass horizontally or vertically over the coil surfaces, removing heat through convection. Since no water evaporation occurs, dry coolers offer significant advantages in water consumption and water treatment requirements. However, their heat exchange efficiency is highly influenced by ambient dry-bulb temperatures, potentially reducing cooling capacity during hot weather.Environmental Suitability Analysis of Both DevicesCooling towers are suitable for scenarios with relatively abundant water resources and high cooling efficiency requirements. In humid and hot climates, their evaporative cooling mechanism maintains stable performance. However, cooling tower systems require water treatment equipment to prevent scaling, biofouling, and corrosion, resulting in relatively higher maintenance costs. Additionally, in low-temperature winter environments, anti-freeze measures such as installing heaters or partial drainage are necessary to prevent pipe bursts.Dry coolers are better suited for water-scarce regions or sites with stringent environmental requirements. Their lack of water replenishment and wastewater discharge needs gives them a clear advantage in arid areas or projects with high environmental standards. Simultaneously, dry cooler systems feature simple structures, lower maintenance demands, and excellent long-term operational stability. Their limitation lies in restricted cooling capacity during high summer temperatures, potentially requiring larger equipment specifications or auxiliary refrigeration methods, which may increase initial investment costs.Energy Consumption and Economic ComparisonFrom the perspective of operating energy consumption, cooling towers, due to their use of evaporative cooling, usually have lower power consumption for fans and pumps, resulting in higher overall energy efficiency, especially under moderate humidity conditions. However, the water consumption and chemical water treatment costs need to be included in the long-term operation and maintenance costs. Additionally, the maintenance and regular cleaning of the water system also require human and material inputs.Dry coolers consume no water but rely on fans to drive airflow. Fan power is typically substantial, especially during high-temperature seasons when full-speed operation is required, leading to higher electricity consumption. However, with the widespread adoption of variable frequency technology, modern dry coolers can adjust fan speed to accommodate load variations, reducing energy consumption during partial load conditions. In cold regions, dry coolers can also utilize natural cooling sources for free cooling, further saving energy.Regarding investment costs, cooling tower systems—which include pumps, water treatment units, and piping—may have lower initial expenditures, but long-term operational and maintenance expenses require careful evaluation. Dry cooler systems feature compact structures and relatively straightforward installation, though equipment costs can be higher, especially when larger heat exchange areas are required.Reliability and Maintenance RequirementsCooling tower operational reliability is significantly influenced by water quality. Improper water treatment can lead to scaling, corrosion, and microbial growth, impairing heat transfer efficiency and potentially damaging equipment. Consequently, regular cleaning, blowdown, and chemical dosing are required, necessitating higher maintenance frequency. Additionally, open cooling towers may pose risks of splash contamination and Legionella growth, requiring appropriate protective measures.Dry cooler is a fully enclosed system, which avoids maintenance issues related to water. Daily maintenance only requires keeping the fins clean and inspecting the fan. The maintenance workload is relatively small. However, the moving parts such as the fan and motor need to be lubricated and inspected regularly to ensure long-term stable operation. In areas with frequent sandstorms, the fins are prone to accumulate dust, and they need to be cleaned frequently to maintain the heat exchange efficiency.System Integration and CompatibilityIn modern data center projects, the selection of cooling equipment also needs to take into account its integration capability with the overall air conditioning system. For instance, whether it supports variable frequency control, whether it can work in conjunction with natural cooling systems, and whether it is compatible with intelligent building management systems, etc. Cooling towers can achieve partial load optimization by adjusting the rotational speed of the fans and the frequency of the water pumps, while dry coolers can enhance the flexibility of regulation through multi-stage fan control and circuit design.Cooling towers and dry coolers each possess distinct advantages and disadvantages. Selection requires comprehensive evaluation of factors including climate conditions, water resource availability, energy pricing, operational capabilities, and long-term costs. In regions with moderate humidity or abundant water resources, cooling towers may offer greater energy efficiency advantages. Conversely, in water-scarce areas or regions with stringent environmental requirements, dry coolers may represent a more sustainable choice. Additionally, hybrid cooling systems—combining the strengths of both technologies and switching operating modes seasonally—are increasingly becoming the preferred solution for large-scale data centers.

Read More>>

All Products

-

Certificated Products

- Customized Heat Sink Cooling Type

-

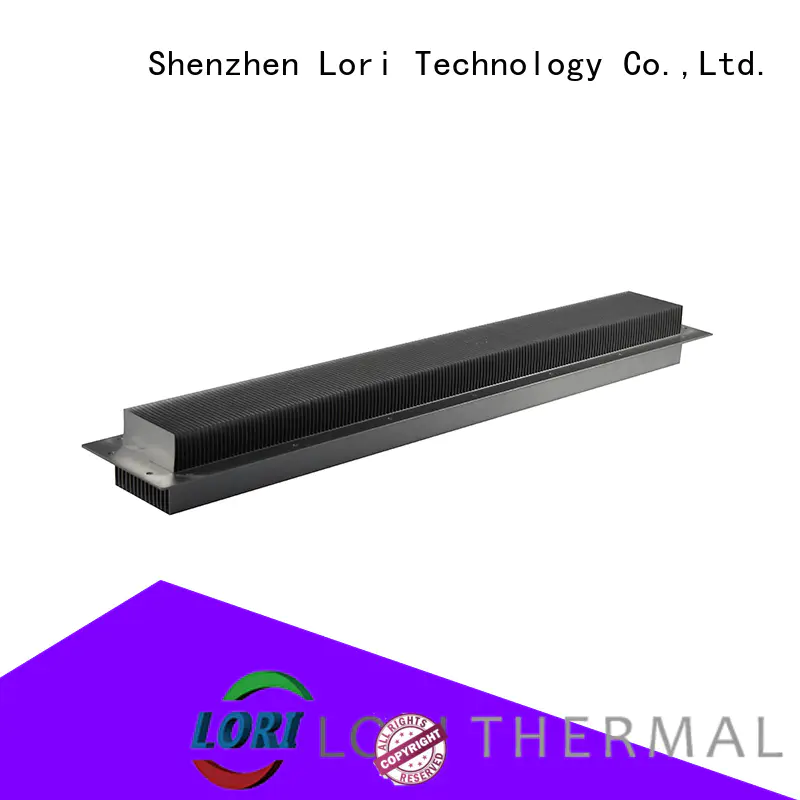

Hot Custom Heat Sink

- Buy Heat Sink Material

-

Friction Stir Welded For sell

- Buy Heat Sink Industries Wholesale

- Liquid Cold Plate Manufacturer

-

Heat Sink Technologies For sell

- Hot Zipper Fin Heat Sinks Warranty

- Quality Stamped Fin Heat Sink Wholesale

- Brazing Heat Sink Wholesale

- Buy Folded Fin Heat Sink Bulk

- Soldering heat sink Supplier

- Certificated Skived Fin Heat Sink Manufacturer

- Buy Stacked fin heat sink For sell

- Heat Pipe Heat Sink Bulk

- Quality Bonded Fin Heat Sink

- Cold Forged Heat Sink For sell

-

Quality Products

-

Buy Friction Stir Welded Warranty

-

Heat Sink Technologies Warranty

- Customized Extruded Heat Sink Supplier

- Best Zipper Fin Heat Sinks Supplier

- Certificated Skived Fin Heat Sink Bulk

- Customized Heat Pipe Heat Sink For sell

- Hot Zipper Fin Heat Sinks

- Certificated Extruded Heat Sink Manufacturer

- Quality Skived Fin Heat Sink For sell

- Customized Folded Fin Heat Sink Wholesale

- Soldering heat sink Exporter

- Buy Stacked fin heat sink Bulk

- Best Extruded Heat Sink Supplier

- Skived Fin Heat Sink Bulk

- Heat Pipe Heat Sink Factory

-

Top Friction Stir Welded Exporter

- Quality Heat Sink Techniques Manufacturer

- Certificated Heat Sink Industries

- Liquid Cold Plate Company

- Liquid Cold Plate Exporter

-

Buy Friction Stir Welded Warranty

- Hot Products

-

Quality Products Factory

-

Friction Stir Welded Wholesale

-

Liquid Cold Plate Warranty

-

Customized Heat Sink Exporter

- Certificated Led Heat Sink Exporter

- Customized Skived Fin Heat Sink Company

- Quality Zipper Fin Heat Sinks

- Quality Extruded Heat Sink

- Quality BGA Heat Sink

- Heat Pipe Heat Sink Company

- Cold Forged Heat Sink Exporter

- Certificated Heat Pipe Heat Sink Exporter

- Buy Led Heat Sink Exporter

- Certificated Soldering heat sink Manufacturer

- Buy Bonded Fin Heat Sink

- Customized Cold Forged Heat Sink

- Buy Stacked fin heat sink

- Extruded Heat Sink Wholesale

- Quality Zipper Fin Heat Sinks Bulk

- Customized Skived Fin Heat Sink Exporter

- Hot Skived Fin Heat Sink Warranty

- Top BGA Heat Sink

- Customized Stacked fin heat sink Bulk

- Customized Skived Fin Heat Sink Factory

- Buy Zipper Fin Heat Sinks

-

Friction Stir Welded Manufacturing

- Quality Heat Sink Bulk

-

Liquid Cold Plate Bulk

-

Certificated Liquid Cold Plate

-

Quality Friction Stir Welded

- Heat Sink Bulk

-

Friction Stir Welded Wholesale

Hot products