Lori Technology, a leading provider of advanced thermal management solutions, will participate in The Battery Show North America 2025, taking place October 6-9, 2025, in the United States. We will showcase its latest innovations at Booth 6709, including liquid-cooled plates and thermal management components for electric vehicle (EV) components, batteries, and energy storage systems.Lori specializes in manufacturing thermal management products, including liquid-cooled plates, heat sinks, and customized cooling solutions for industries such as electric vehicles, renewable energy, and consumer electronics. With a focus on design, R&D, production, and quality, Lori delivers high-performance thermal solutions to global customers. Visitors will have the opportunity to explore multiple core products designed to enhance thermal performance, reliability, and efficiency in battery energy storage and electric vehicle applications:Key Types of Battery Energy Storage Liquid Cooling Plates

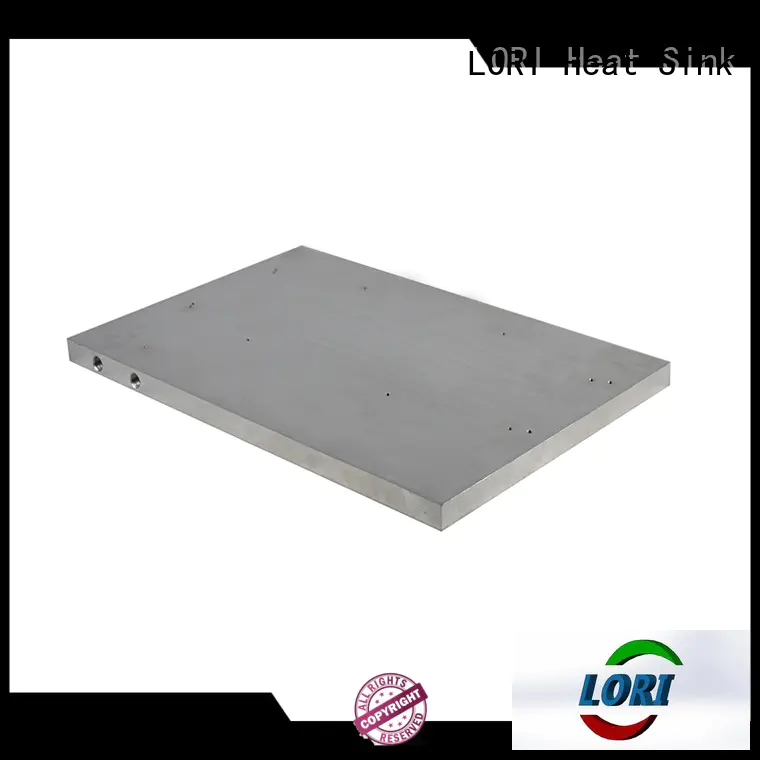

Embedded Tube Battery Liquid Cooling PlateMinimizes thermal resistance by placing cooling tubes directly in contact with the battery surface, offering a cost-effective thermal management solution.

Brazed Battery Liquid Cooling PlatesUtilizing brazing technology, these plates deliver exceptional thermal performance and lightweight design, ideal for high-power applications.

EV Battery Pack Liquid Cooling PlatesFeaturing precision-stamped aluminum construction and IP67 waterproof rating, these plates extend battery cycle life by up to 25% while reducing weight by 30% compared to traditional steel solutions.

Friction Stir Welded (FSW) Battery Liquid Cooling PlateUtilizes FSW technology for flexible design and enhanced seal reliability, with hard anodized surfaces for increased durability.EV Components

1.Water Cooling Motor Housing

2.Controller Liquid Cooling Housing

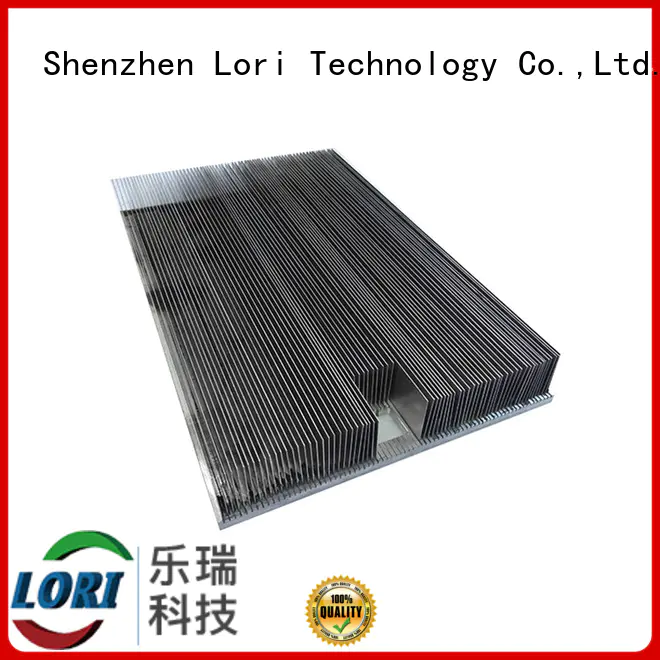

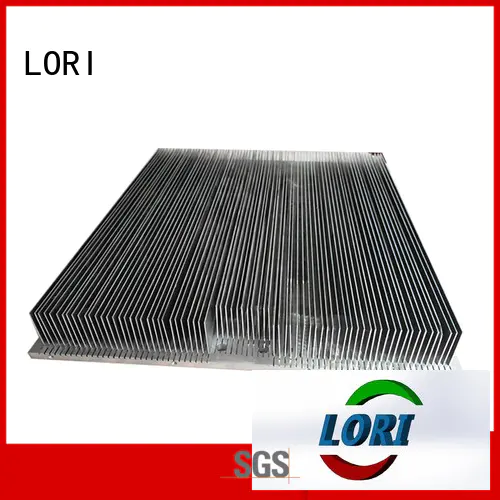

3.Converter Air Cooling Heat Sink

4. Automotive Die-cast Heat SinkLori is delighted to participate in the Battery Show, engaging with peers and showcasing our cutting-edge thermal management technologies. We specialize in customized thermal solutions designed to meet the growing demands of the electric vehicle and battery industries for higher efficiency, lighter weight, and extended lifespan. Serving global customers in the new energy vehicle and battery sectors, our products comply with international standards such as IATF16949 and are widely applied in passenger vehicles, commercial vehicles, and battery energy storage systems.Lori cordially invites attendees to visit Booth 6709 to discuss customized thermal solutions, view product demonstrations, and collect informational brochures.

Read More>>

All Products

-

Certificated Products

- Customized Heat Sink Cooling Type

-

Hot Custom Heat Sink

- Buy Heat Sink Material

-

Friction Stir Welded For sell

- Buy Heat Sink Industries Wholesale

- Liquid Cold Plate Manufacturer

-

Heat Sink Technologies For sell

- Hot Zipper Fin Heat Sinks Warranty

- Quality Stamped Fin Heat Sink Wholesale

- Brazing Heat Sink Wholesale

- Buy Folded Fin Heat Sink Bulk

- Soldering heat sink Supplier

- Certificated Skived Fin Heat Sink Manufacturer

- Buy Stacked fin heat sink For sell

- Heat Pipe Heat Sink Bulk

- Quality Bonded Fin Heat Sink

- Cold Forged Heat Sink For sell

-

Quality Products

-

Buy Friction Stir Welded Warranty

-

Heat Sink Technologies Warranty

- Customized Extruded Heat Sink Supplier

- Best Zipper Fin Heat Sinks Supplier

- Certificated Skived Fin Heat Sink Bulk

- Customized Heat Pipe Heat Sink For sell

- Hot Zipper Fin Heat Sinks

- Certificated Extruded Heat Sink Manufacturer

- Quality Skived Fin Heat Sink For sell

- Customized Folded Fin Heat Sink Wholesale

- Soldering heat sink Exporter

- Buy Stacked fin heat sink Bulk

- Best Extruded Heat Sink Supplier

- Skived Fin Heat Sink Bulk

- Heat Pipe Heat Sink Factory

-

Top Friction Stir Welded Exporter

- Quality Heat Sink Techniques Manufacturer

- Certificated Heat Sink Industries

- Liquid Cold Plate Company

- Liquid Cold Plate Exporter

-

Buy Friction Stir Welded Warranty

- Hot Products

-

Quality Products Factory

-

Friction Stir Welded Wholesale

-

Liquid Cold Plate Warranty

-

Customized Heat Sink Exporter

- Certificated Led Heat Sink Exporter

- Customized Skived Fin Heat Sink Company

- Quality Zipper Fin Heat Sinks

- Quality Extruded Heat Sink

- Quality BGA Heat Sink

- Heat Pipe Heat Sink Company

- Cold Forged Heat Sink Exporter

- Certificated Heat Pipe Heat Sink Exporter

- Buy Led Heat Sink Exporter

- Certificated Soldering heat sink Manufacturer

- Buy Bonded Fin Heat Sink

- Customized Cold Forged Heat Sink

- Buy Stacked fin heat sink

- Extruded Heat Sink Wholesale

- Quality Zipper Fin Heat Sinks Bulk

- Customized Skived Fin Heat Sink Exporter

- Hot Skived Fin Heat Sink Warranty

- Top BGA Heat Sink

- Customized Stacked fin heat sink Bulk

- Customized Skived Fin Heat Sink Factory

- Buy Zipper Fin Heat Sinks

-

Friction Stir Welded Manufacturing

- Quality Heat Sink Bulk

-

Liquid Cold Plate Bulk

-

Certificated Liquid Cold Plate

-

Quality Friction Stir Welded

- Heat Sink Bulk

-

Friction Stir Welded Wholesale

Hot products